Why Understanding Rebar Requirements Matters for Your 4-Inch Slab

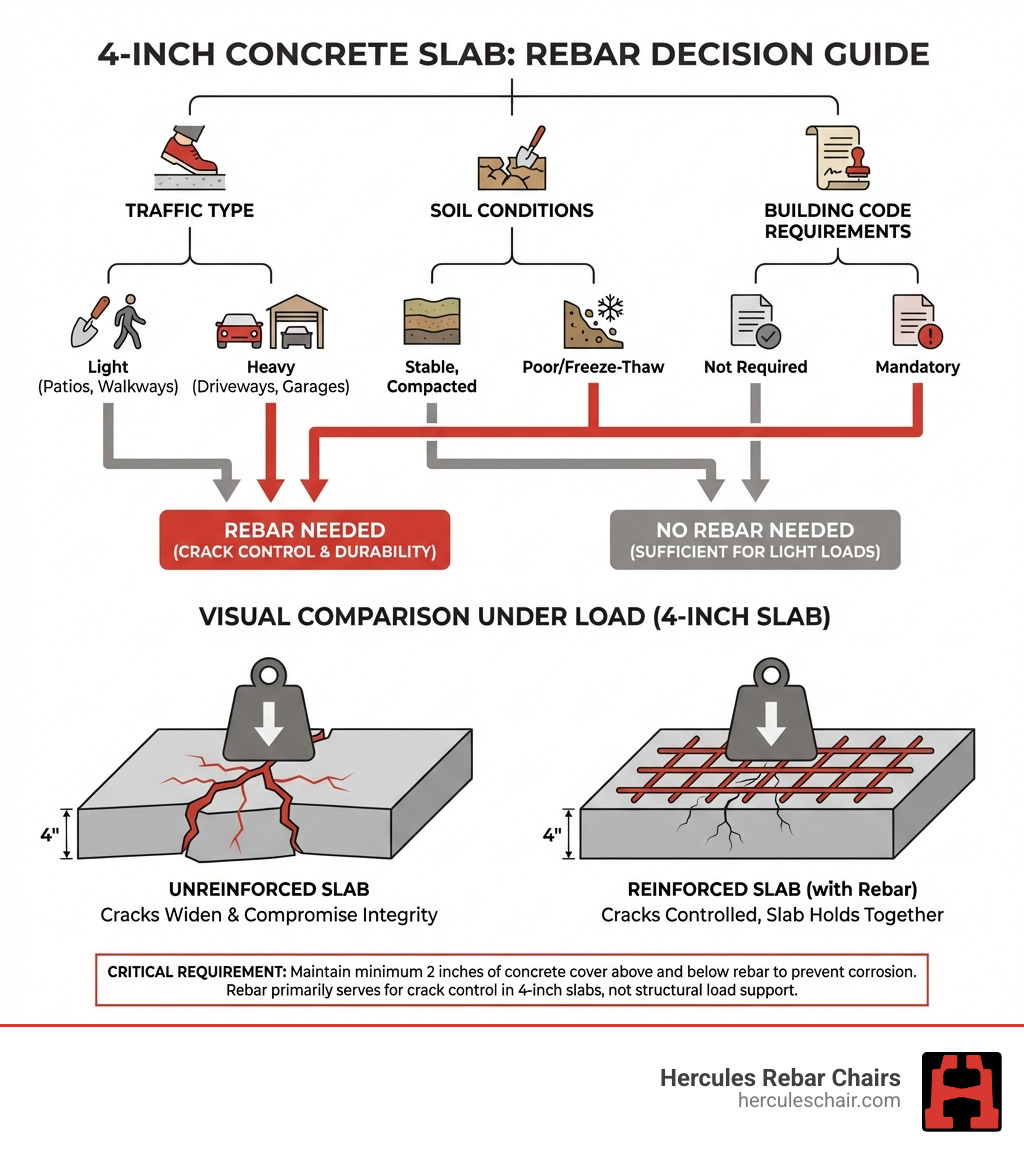

Rebar in 4 inch slab is one of the most debated topics among concrete contractors and DIYers. The short answer: it depends on your specific application, load requirements, and local building codes.

Quick Answer: Do You Need Rebar?

- Skip rebar for: Light-traffic patios, garden walkways, stable soil conditions, and small residential slabs with minimal loads

- Use rebar for: Driveways with vehicle traffic, garage floors, areas with poor soil or freeze-thaw cycles, and any application required by local building codes

- Recommended specs: #3 or #4 rebar at 18-24 inches on center when reinforcement is needed

- Critical requirement: Minimum 2 inches of concrete cover to prevent corrosion

Here’s the thing most people get wrong about thin concrete slabs: they assume rebar always makes them stronger. But a 4-inch slab is actually too thin for rebar to provide structural support in the traditional sense. When placed at the center of the slab (where it needs 2 inches of cover), the rebar sits at the point of zero stress, offering minimal structural benefit.

That doesn’t mean rebar is useless in a 4-inch slab. It serves a different purpose: crack control. Properly placed rebar won’t prevent cracks from forming, but it holds the concrete together once cracks appear, preventing them from widening and compromising the slab’s integrity.

The real question isn’t “do I need rebar?” but rather “what loads will this slab handle, what’s my soil condition, and what do my local codes require?” For many residential applications like patios with light foot traffic on stable, well-compacted soil, you can skip the rebar and focus on proper concrete placement, curing, and control joints. But for driveways, garage floors, or areas with challenging soil conditions, rebar becomes essential for long-term durability.

In this guide, we’ll cut through the confusion and help you make an informed decision based on your specific project needs, ensuring you don’t waste money on unnecessary reinforcement or risk structural failure by skipping it when it matters.

The Verdict on Rebar: When to Use It and When to Skip It

Deciding whether to use rebar in 4 inch slab projects can feel like navigating a maze. The truth is, there’s no one-size-fits-all answer. It largely depends on the intended use of the concrete slab, the conditions of the ground beneath it, and, crucially, your local building codes. Understanding these factors will help you make an informed decision, saving you both time and money.

A 4-inch concrete slab poured directly on grade, meaning it’s in permanent contact with the ground, often functions as a “floating slab.” This means it’s designed to move slightly with the ground, and in many cases, especially for light loads, rebar isn’t strictly necessary for structural support. However, for heavier loads or less stable ground, the story changes dramatically.

When Rebar is Often Unnecessary

For many common residential projects across the USA, from Alabama to Wyoming, rebar in 4 inch slab applications can often be skipped, especially when:

- Light Foot Traffic: If your project is a small patio, a simple garden path, or a sidewalk that will only see light foot traffic, the need for rebar significantly diminishes. These areas generally don’t experience the kind of heavy point loads or sustained stress that would necessitate steel reinforcement.

- Stable, Well-Compacted Soil: A solid, well-prepared sub-base is paramount. If your soil is stable, properly graded, and thoroughly compacted, it provides excellent uniform support for the slab. In such conditions, the concrete itself, with proper mix design and curing, can handle the anticipated loads.

- Cost Savings & Simplified Pour: Opting out of rebar can lead to noticeable cost savings on materials and labor. It also simplifies the pouring process, as there’s no need to carefully place and support a rebar grid. This can be a significant advantage for DIY enthusiasts looking to simplify their project.

The consensus among many experts is that for a 4-inch-thick slab cast directly on the ground and in permanent contact with it, the slab will “float,” and structural rebar is not required in these specific, low-stress scenarios.

When Rebar is Highly Recommended

While we’ve discussed when to skip rebar, there are many critical situations where incorporating rebar in 4 inch slab projects is not just recommended, but essential for longevity and safety.

- Vehicular Traffic & Heavy Loads: Think driveways, garage floors, or RV pads. These areas are subjected to significant weight and dynamic loads from vehicles. For a concrete driveway that is normally 4 to 6 inches thick, #3 rebar placed in a grid at approximately 18 to 24 inches on center is typically sufficient. For thicker slabs or heavier traffic, #4 rebar might be necessary. This reinforcement helps the slab resist bending and cracking under the stress of tires and vehicle weight.

- Foundations for Structures: If your 4-inch slab is part of a foundation for a shed, a small outbuilding, or even a foundation wall, rebar provides crucial structural integrity. It helps distribute loads more evenly and prevents localized failure.

- Poor Soil Conditions: Expansive soils (common in parts of the Southwest and Midwest), poorly compacted fill, or areas prone to settling can put immense stress on a concrete slab. Rebar acts as an internal skeleton, holding the concrete together and mitigating the effects of soil movement.

- Areas with Significant Temperature Swings (Freeze-Thaw Cycles): Many regions across the USA, from the frigid North Dakota winters to the fluctuating temperatures in the Mid-Atlantic, experience freeze-thaw cycles. These cycles cause the ground to heave and settle, which can lead to significant cracking. In these environments, #4 epoxy-coated rebars are often recommended as they reduce corrosion risks by 40% and comply with ASTM A615 standards, offering superior protection against the elements. Proper spacing of rebar can prevent 85% of slab cracks caused by thermal expansion alone.

- Local Building Code Requirements: This is perhaps the most important consideration. Regardless of your project’s apparent simplicity or light load, local building codes in your state or county may mandate specific rebar requirements for all concrete slabs, including 4-inch applications. Always check with your local planning or building department before starting any project. They can provide definitive guidance on rebar size, spacing, and placement that is specific to your area.

Understanding Rebar’s Role: Strength, Cracks, and Durability

The discussion around rebar in 4 inch slab projects often centers on its core purpose: making concrete stronger and more durable. While concrete excels in resisting compression (being squished), it’s notoriously weak in tension (being pulled apart or bent). This is where rebar steps in, providing the tensile strength that concrete lacks. It’s a partnership, like a strong bodybuilder (concrete) supported by a flexible gymnast (rebar).

The Benefits of Reinforcement

When we talk about reinforcing a 4-inch slab, even if it’s not for “structural support” in the traditional sense, rebar offers several undeniable advantages:

- Increased Tensile Strength: Rebar dramatically improves concrete’s ability to withstand pulling and bending forces. This is crucial for slabs that might experience uneven loads or subtle ground movement.

- Impact Resistance & Bending Stress Management: A reinforced slab is far better equipped to handle sudden impacts or continuous bending stress, which can occur from heavy foot traffic, falling objects, or even slight shifts in the sub-base.

- Holds Cracks Together: This is the big one for 4-inch slabs. Rebar doesn’t prevent cracks from forming – concrete will crack due to shrinkage, temperature changes, and curing. However, once a crack appears, the rebar holds the fractured pieces tightly together. This prevents the crack from widening into a gaping fissure, maintaining the slab’s load-carrying ability and overall integrity. Without rebar, those small hairline cracks can quickly propagate and become structural liabilities.

- Uniform Material Behavior: Rebar helps the concrete behave as a more unified composite material. This means that instead of breaking apart into separate pieces, the slab remains cohesive, distributing any stresses more effectively across its entire area. This contributes significantly to the slab’s longevity.

The Risks of Using Rebar Incorrectly

While beneficial, simply throwing rebar in 4 inch slab projects without proper knowledge can be counterproductive, leading to wasted effort and even compromising the slab’s performance.

- Improper Concrete Cover: This is a critical error. The American Concrete Institute (ACI) recommends a minimum of 2 inches of concrete cover for rebar in slabs. If the rebar is placed too close to the surface, it’s exposed to moisture and air. The alkalinity of concrete usually protects rebar from corrosion, but carbonation (from exposure to air) can reduce this protection.

- Rust and Expansion (Spalling): When rebar rusts, it expands up to nine times its original volume. This expansion creates internal pressure that can cause the surrounding concrete to crack and “spall” (chip or flake off). This not only looks terrible but also weakens the slab and exposes more rebar to corrosion.

- Reduced Load Capacity: If rebar is placed too shallow or too deep, it can actually reduce the slab’s load-bearing capabilities by up to 20%. For a 4-inch slab, placing rebar precisely in the middle (2 inches from the top and bottom) to achieve proper cover means it sits in the theoretical “point of zero stress” for structural purposes. This is why, for thin slabs, its primary role shifts from structural reinforcement to crack control.

- Wasted Cost and Effort: If rebar is incorrectly placed or unnecessary for your specific application, you’ve spent money on materials and labor that provide little to no benefit. It’s like buying a parachute but forgetting to pack it when you jump.

Understanding these risks underscores the importance of proper rebar placement. For more detailed insights into ensuring your rebar is positioned perfectly, we invite you to explore our comprehensive Rebar Placement Guide.

Best Practices for Installing Rebar in a 4-Inch Slab

Proper installation is key to using the benefits of rebar in 4 inch slab projects. It’s not enough to just lay the rebar down; its size, spacing, and precise placement within the concrete are paramount for effective reinforcement and long-term durability. We’ve seen countless projects across the country, from busy commercial sites to quiet backyard patios, and the common thread for success is always meticulous planning and execution.

Recommended Rebar Sizes and Spacing for a 4-inch slab

For a 4-inch slab, the goal of rebar is primarily crack control. Here’s what we typically recommend based on industry standards and common practice:

- Rebar Sizes:

- #3 Rebar (3/8-inch diameter): This is a common and effective choice for residential 4-inch slabs, especially for patios and light-duty driveways.

- #4 Rebar (1/2-inch diameter): For areas expecting slightly heavier loads or light commercial use, #4 rebar provides a bit more strength and is a solid option. You can find Details on #4 Rebar specifications to help you understand its properties.

- Spacing:

- For a standard 4-inch thick slab using #3 or #4 rebar, aim for about 18-24 inches on center in a grid pattern. “On center” means measuring from the center of one rebar to the center of the next.

- For residential use, particularly for driveways, some recommendations suggest spacing #3 rebars at 12-inch intervals for improved crack control.

- Always create a grid pattern, with rebar running perpendicular and parallel to each other. This ensures better load distribution and helps the slab act as a unified unit.

- When rebar sections overlap (known as lapping), they should overlap by at least 24 inches and be securely tied together with tie wire. This ensures continuity of reinforcement.

The Critical Importance of Rebar Placement and Cover

This is arguably the most crucial aspect of using rebar in 4 inch slab applications. Even the right size and spacing won’t help if the rebar isn’t positioned correctly.

- Mid-Slab Placement: The ideal placement for rebar in a 4-inch slab for crack control is as close to the middle as possible. This means approximately 2 inches from the top surface and 2 inches from the bottom surface. This ensures the rebar is embedded where it can best resist tensile forces from both upward and downward bending.

- 2-inch Concrete Cover: As per American Concrete Institute (ACI) recommendations, a minimum of 2 inches of concrete cover is essential. This cover protects the rebar from moisture, oxygen, and corrosive elements, preventing rust and subsequent spalling. It also insulates the rebar from extreme temperatures, which could cause expansion and contraction, further stressing the concrete.

- Using Rebar Chairs for Elevation: Achieving and maintaining this precise mid-slab placement is where tools like rebar chairs become indispensable. We, at Hercules Rebar Chairs, specialize in manufacturing strong, reliable concrete supports that ensure your rebar stays exactly where it needs to be during the concrete pour. Our red rebar chairs are “America’s #1” with millions sold, known for saving time and money while ensuring code compliance. They lift the rebar off the sub-base, preventing it from sinking during the pour. You can explore Our Products to see how they can simplify your project.

- Edge Clearance: Ensure rebar is placed at least 2-3 inches from any edge of the slab. This ensures full concrete encasement and prevents the rebar from being too close to the surface where it could corrode or cause edge spalling.

Calculating Rebar Needs and Navigating Codes for a 4-inch slab

Before you even think about pouring, calculate your rebar needs accurately and, most importantly, understand your local building codes.

- Local Building Codes: We cannot stress this enough: always consult your local building department. Building codes vary significantly from state to state and even county to county across the USA, from California to New York. What’s acceptable for a patio in Florida might not be for a driveway in Minnesota due to different soil conditions, seismic activity, or freeze-thaw cycles. These codes will dictate minimum rebar size, spacing, and cover requirements for various applications.

- Engineering Specifications: For larger or more complex projects, or if you have challenging site conditions, a licensed structural engineer can provide project-specific designs. They will consider factors like soil bearing capacity, anticipated loads, and environmental stresses to specify the exact rebar requirements.

- Calculating Rebar Quantity: To estimate the amount of rebar you’ll need, you’ll calculate the total linear feet required for your grid pattern. For instance, a 10×10 foot slab with 18-inch on-center spacing would require 7 pieces of rebar each 10 feet long in one direction, and 7 pieces in the perpendicular direction, totaling 140 linear feet. Our Hercules Rebar Chair Estimator can help you quickly determine how many chairs you’ll need for your project, ensuring your rebar stays put. For more comprehensive rebar and concrete calculations, you can use an Online rebar calculator tool.

Here’s a simplified table for estimated rebar needs for common 4-inch slab sizes, assuming 18-inch on-center spacing:

| Slab Size (Feet) | Linear Feet of #3 or #4 Rebar (approx.) |

|---|---|

| 10 x 10 | 140 |

| 10 x 20 | 280 |

| 12 x 12 | 192 |

| 15 x 15 | 300 |

| 20 x 20 | 520 |

Note: These are estimates. Always calculate based on your specific dimensions and desired spacing, and factor in overlaps for lapping.

Beyond Rebar: Essential Use Cases and Considerations

While we’ve digd into the specifics of rebar in 4 inch slab projects, reinforcement is just one piece of the puzzle. The overall success and longevity of your concrete slab also depend on meticulous planning, proper sub-base preparation, a quality concrete mix, and effective curing. These elements work in concert to create a durable surface.

When making decisions about your concrete project, always consider the big picture. What will this slab be used for throughout its lifetime? What are the environmental challenges in your area? Is the soil stable, or does it have a tendency to shift? These project-specific needs, coupled with load requirements and local codes, should guide your choices. A well-constructed slab, whether reinforced or not, begins with a solid foundation (literally!).

When Rebar is the Best Choice

Even if a 4-inch slab floats on grade, there are clear scenarios where rebar simply makes sense and provides peace of mind.

- Structural Reinforcement (where applicable): While a 4-inch slab might be too thin for rebar to provide traditional structural support in its center, for thicker slabs (5-6 inches) or areas with specific structural demands (like thickened edges or footings under a wall), rebar is undeniably structural. Even in a 4-inch slab, it improves the slab’s ability to span minor inconsistencies in the sub-base and provides added resilience against localized stresses.

- Superior Crack Control: As we’ve discussed, rebar is a champion of crack control. It won’t prevent cracks, but it will keep them tight and manageable, preventing them from becoming eyesores or structural weaknesses. This is particularly valuable for visible surfaces like patios or driveways where aesthetics matter.

- Long-Term Durability: Investing in proper reinforcement with rebar, especially when supported by quality rebar chairs, significantly extends the lifespan of your concrete slab. It helps the slab withstand the test of time, resisting the wear and tear of daily use, environmental factors, and unforeseen stresses.

- Compliance with Codes: In many jurisdictions across the USA, from the busy cities of Texas to the serene landscapes of Oregon, building codes will simply mandate rebar for certain applications, even for 4-inch slabs. Adhering to these codes isn’t just about legality; it’s about ensuring safety and quality standards for your project.

- Use of Rebar Chairs for Correct Placement: We can’t overstate the importance of getting rebar placement right. Our Hercules Rebar Chairs are designed precisely for this purpose, ensuring your rebar is liftd to the correct height and remains stable during the pour. This small investment in proper support makes a monumental difference in the effectiveness of your reinforcement, helping you save time and money by avoiding costly mistakes down the line.

Frequently Asked Questions about Rebar in Concrete Slabs

We understand that working with concrete and rebar can bring up a lot of questions. Here are some of the most common ones we hear, specifically related to rebar in 4 inch slab projects:

Does rebar stop concrete from cracking?

No, rebar does not prevent concrete from cracking. This is one of the most common misconceptions. Concrete naturally shrinks as it cures and will crack due to this shrinkage, as well as from temperature changes and ground movement. What rebar does do, exceptionally well, is hold those cracks tightly together. Instead of a crack widening and compromising the slab’s structural integrity, the rebar acts like a stitch, keeping the two sides of the crack from separating, thus maintaining the slab’s load-bearing capacity and aesthetic appeal.

What is the best rebar size for a 4-inch driveway slab?

For a standard residential driveway that is 4 to 6 inches thick, #3 rebar (3/8-inch diameter) is typically sufficient. For slightly heavier traffic or more demanding conditions, #4 rebar (1/2-inch diameter) might be a better choice. In both cases, the rebar should be placed in a grid pattern at approximately 18 to 24 inches on center. However, the most important step is always to check with your local building codes in your specific state (e.g., from Washington to Maine), as requirements can vary significantly.

Can I use rebar and wire mesh together?

While it’s technically possible to use both rebar and wire mesh in a concrete slab, it’s often redundant and usually not necessary for a typical 4-inch slab. Wire mesh is primarily used for surface crack control, helping to minimize minor cracking in the top layer of the concrete. Rebar, on the other hand, provides more robust reinforcement against bending stresses and helps hold larger cracks together.

In most 4-inch slab applications, if you’ve properly designed and placed your rebar, adding wire mesh might not provide significant additional benefit. It could even complicate placement, making it harder to ensure both are at their optimal depths. If you’re considering using both, we strongly recommend consulting a structural engineer to ensure it’s justified for your project and that both materials can be correctly positioned without interfering with each other’s effectiveness. Often, focusing on proper rebar placement with quality supports like our rebar chairs is a more effective and efficient approach.

Conclusion

Navigating rebar in 4 inch slab projects can seem complex, but with the right information, you can make an informed decision that ensures the longevity and durability of your concrete. We’ve learned that while rebar isn’t always a structural necessity for thin slabs, it plays a critical role in crack control and overall slab integrity, especially under heavy loads, in poor soil conditions, or in areas with harsh freeze-thaw cycles.

Remember to always consider your project-specific needs, including the anticipated load-bearing capacity, the condition of your soil, and, most importantly, your local building codes. Proper installation, with careful attention to rebar size, spacing, and precise placement using reliable supports, is paramount.

At Hercules Rebar Chairs, we are committed to providing the concrete construction industry across the USA with “America’s #1” rebar chairs, designed to save you time and money while ensuring your projects are code-compliant and built to last. For all your rebar placement needs, trust our red rebar chairs to keep your reinforcement exactly where it needs to be.

For further detailed guidance on ensuring your rebar is perfectly positioned for maximum effectiveness, we encourage you to consult our comprehensive Rebar Placement Guide.