Why Finding the Right Concrete Contractor Supplies Partner Matters

Concrete contractor supplies are the backbone of every successful project—from the rebar chairs that support your reinforcement to the finishing tools that create a flawless surface. Finding reliable suppliers can make or break your timeline, budget, and reputation.

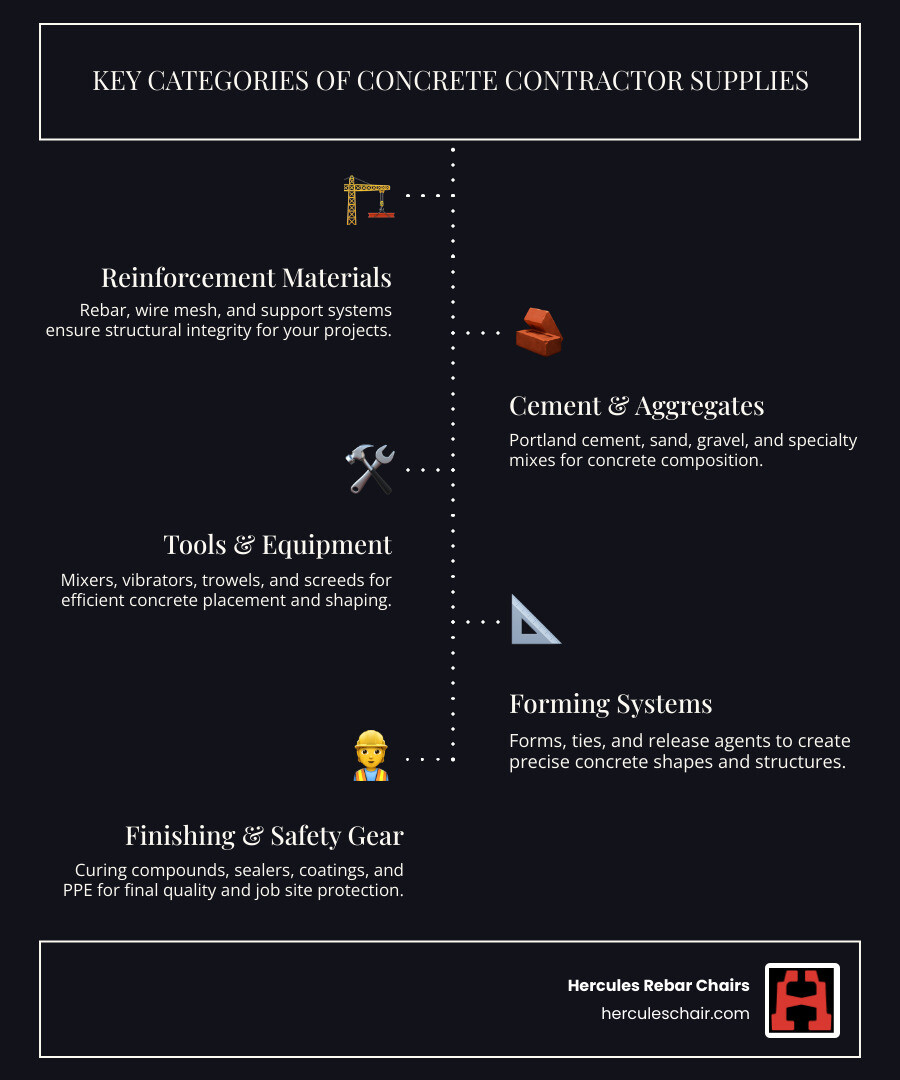

Top categories of concrete contractor supplies include:

- Reinforcement materials – Rebar, wire mesh, and support systems

- Cement and aggregates – Portland cement, sand, gravel, and specialty mixes

- Tools and equipment – Mixers, vibrators, trowels, and screeds

- Forming systems – Forms, ties, and release agents

- Finishing supplies – Curing compounds, sealers, and coatings

- Safety gear – PPE for job site protection

The difference between a smooth-running job and a costly disaster often comes down to one thing: your supply partner. When materials show up late or don’t meet spec, you’re the one scrambling to keep crews working and clients happy.

A strong supplier relationship means more than just getting products delivered. It means having access to technical expertise when you need it. It means knowing someone will pick up the phone when you’re short on materials mid-pour. And it means competitive pricing that protects your margins without sacrificing quality.

Whether you’re pouring foundations, installing rebar, or finishing surfaces, the right supplies—delivered on time—keep your projects on track and profitable. For a deeper overview of how concrete is made and used, resources like the Portland cement entry on Wikipedia can also help you better understand the core materials behind your supply needs.

How to Evaluate a Concrete Supply Partner

Choosing the right partner for your concrete contractor supplies is a critical business decision. It’s not just about finding the cheapest option; it’s about securing reliability, quality, and service that supports your project’s success. We believe a truly valuable supplier becomes an extension of your team, helping you steer challenges and ensuring smooth operations.

When we evaluate a potential supplier, we look for several key indicators:

- Product Range and Quality: Does the supplier offer a comprehensive selection of concrete contractor supplies that meet the diverse needs of our projects? More importantly, is the quality consistently high? We need to know that the cement will perform as expected, the rebar will meet strength requirements, and tools will withstand the rigors of a job site. A supplier with a wide range of reputable brands and quality control measures is invaluable.

- Inventory Availability: Nothing stalls a project faster than waiting for materials. We prioritize suppliers who maintain robust inventory levels of commonly used items. This means less downtime for our crews and fewer unexpected delays. For specialized items, we need clear communication about lead times.

- Delivery Speed and Reliability: Timely delivery is non-negotiable. A supplier’s ability to get materials to our job site when and where we need them, consistently and reliably, speaks volumes about their operational efficiency. This includes having a well-maintained fleet and competent delivery personnel.

- Customer Service: When issues arise—and they sometimes do—responsive and helpful customer service is paramount. We look for partners who are easy to communicate with, proactive in addressing concerns, and committed to finding solutions quickly. Good customer service can turn a potential problem into a minor hiccup.

- Technical Expertise: The best suppliers offer more than just products; they offer knowledge. Having access to their technical experts for advice on product applications, material specifications, or troubleshooting on the job site can be a huge asset. They can help us choose the right admixture for a specific climate or understand the nuances of a new curing compound.

What to ask a potential supplier

Before committing to a supplier for your concrete contractor supplies, we always recommend asking targeted questions to ensure transparency and align expectations. This due diligence can save you headaches and money down the line.

- Delivery fees: Are they flat-rate, mileage-based, or do they vary by order size? Are there minimum order requirements to avoid a delivery charge? Understanding the cost structure upfront helps us budget accurately.

- Return policies: What are the conditions for returning unused or incorrect materials? Are there restocking fees? Knowing the process for returns can be crucial if project plans change or errors occur.

- Bulk pricing: Do they offer discounts for large-volume orders? How can we qualify for better pricing as a repeat customer or for substantial purchases? Building a relationship can often lead to more favorable terms over time.

- Lead times for special orders: If we need a non-stock item, how long can we expect to wait? This is vital for planning and scheduling projects that require unique or custom concrete contractor supplies.

Why a reliable supplier is crucial

In our experience, partnering with a reliable supplier for concrete contractor supplies isn’t a luxury; it’s a necessity for profitability and reputation.

- Avoiding project delays: Every minute counts on a construction site. Delayed material deliveries mean idle crews, missed deadlines, and potential penalties. A reliable supplier ensures materials are there when you need them, keeping your project on schedule.

- Ensuring material quality: Substandard materials can compromise the integrity of your work, leading to costly rework, structural failures, and damage to your company’s reputation. A trustworthy supplier consistently provides high-quality products that meet all specifications and industry standards.

- Access to expert advice: Sometimes, we encounter unique challenges that require specialized knowledge. A good supplier’s technical team can offer invaluable guidance, helping us select the best products or techniques for complex situations. This partnership approach can save time and prevent costly mistakes.

- Streamlining procurement: An efficient supplier simplifies the ordering process, reduces administrative burdens, and makes invoicing straightforward. This allows our team to focus more on construction and less on chasing down orders or reconciling invoices.

Types of Concrete Supply Companies

This section helps you understand the landscape of suppliers without focusing on specific brand names, allowing you to find the right fit for your needs.

When we’re looking for concrete contractor supplies, we know there isn’t a one-size-fits-all solution. The market offers a variety of supplier types, each with its own advantages and disadvantages. Understanding these different models helps us choose the best fit for a particular project’s scale, location, and specific material needs across our operations in states like California, Texas, Florida, and beyond.

National Retail Chains

These are often the big-box stores or large construction material suppliers with a presence in many states.

- Pros: They typically boast a large inventory, meaning you can often find common concrete contractor supplies readily available. Their multiple locations across the USA, from New York to Arizona, offer convenience, and their pricing tends to be standardized, which can simplify budgeting. They often have robust online ordering systems, making procurement accessible.

- Cons: While convenient, national chains may offer less personalized service. You might interact with different staff members each time, making it harder to build a strong relationship. They may also not stock highly specialized or niche concrete contractor supplies, requiring you to look elsewhere for unique admixtures or custom rebar configurations.

Local and Regional Distributors

These suppliers focus on a specific geographic area, often serving a city, county, or a few neighboring states.

- Pros: We often find that local and regional distributors possess deep local knowledge. They understand regional building codes, common practices, and even local weather patterns that affect concrete work. This specialized insight can be incredibly valuable. They tend to build strong relationships with contractors, offering more personalized service and potential flexibility in terms of delivery schedules or specific product requests.

- Cons: Their service area is, by definition, smaller, which might not be ideal for projects spanning vast distances. Their stock might also be more limited compared to national chains, especially for less common concrete contractor supplies. However, for most day-to-day needs, they are often a fantastic resource.

Online and Specialty Suppliers

This category includes e-commerce platforms and companies that specialize in a very specific type of concrete contractor supplies, often shipping nationwide.

- Pros: The convenience of ordering from anywhere, at any time, is a significant advantage. These suppliers often provide access to niche products that might be hard to find locally, such as specific chemical admixtures, unique decorative concrete tools, or specialized rebar supports. Their online model can sometimes lead to competitive pricing due to lower overhead.

- Cons: Shipping costs and potential delays, especially for heavy or bulky concrete contractor supplies, can be a drawback. You also lose the ability to physically inspect products before purchase, which can be a concern for certain materials. Customer service might be less immediate compared to local distributors, relying more on email or phone support.

Essential Concrete Contractor Supplies You’ll Need

A comprehensive list ensures you’re prepared for any job, from foundation to finish.

No matter the scale of your project, having the right concrete contractor supplies on hand is paramount. From the foundational elements that bear the load to the tools that create a perfect finish, every item plays a critical role. We’ve learned that being well-stocked not only keeps projects moving but also improves the quality and longevity of our work.

Foundational and Reinforcement Materials

These are the backbone of any concrete structure, providing strength and stability.

- Cement and aggregates: The very building blocks of concrete. We rely on various types of Portland cement (Type I, II, III for different strength and setting times), along with sand, gravel, and crushed stone as aggregates. The right mix design is crucial for achieving desired strength and workability.

- Chemical admixtures: These are vital for modifying concrete properties. We use water reducers to improve workability without adding water, accelerators to speed up setting times in colder climates (common in places like Alaska or Montana), retarders to slow down setting in hot conditions (like in Texas or Florida), and air-entraining agents to improve freeze-thaw resistance, especially important in states with harsh winters such as Wisconsin or New York. For additional background on how these admixtures work, the Concrete admixture overview on Wikipedia can be a helpful reference.

- Rebar and wire mesh: Steel reinforcement is essential for concrete’s tensile strength. We use various grades and sizes of rebar (e.g., #4, #5) and welded wire mesh to prevent cracking and improve structural integrity, ensuring our projects meet strict engineering standards.

- Rebar supports and chairs: This is where we truly shine! Proper placement of rebar is critical; it must be held in the correct position within the concrete pour to perform its job effectively. Our strong, red Hercules Rebar Chairs are designed precisely for this purpose, ensuring rebar maintains its specified cover and spacing, guaranteeing code compliance and superior structural performance. They are “America’s #1” with over 14 million units sold because they save time and money on the job site. You can find detailed information about proper rebar footing support techniques and best practices on our site.

Essential tools for your concrete contractor supplies list

Efficiency and quality on a concrete job site depend heavily on having the right tools.

- Concrete mixers: For smaller jobs or on-site mixing, we use drum or paddle mixers. For larger pours, we coordinate with ready-mix trucks.

- Power trowels: These machines, whether walk-behind or ride-on, are indispensable for achieving a smooth, dense, and durable finish on large concrete slabs. They significantly reduce the manual labor involved in finishing.

- Concrete vibrators: Essential for consolidating concrete after it’s placed. Internal vibrators remove air pockets, ensuring a dense, strong, and void-free slab, which is critical for structural integrity.

- Screeds and floats: Screeds (manual or power) are used to level the concrete surface, bringing it to the desired grade. Floats, such as bull floats and hand floats, are then used to smooth the surface and bring the cream to the top, preparing it for finishing.

Forms, Finishing, and Safety Gear

These categories complete the concrete process, ensuring the final product is shaped correctly, protected, and that our crew is safe.

- Concrete forming systems: We use various forming materials—wood, metal, or plastic—to create the desired shape and dimensions of our concrete structures. Ties, clamps, and form release agents are equally important to ensure forms hold during the pour and can be removed cleanly afterward.

- Curing compounds and blankets: Proper curing is non-negotiable for achieving concrete’s full strength and durability. Curing compounds spray a protective film, while curing blankets provide insulation and moisture retention, especially vital in extreme temperatures, from the heat of Arizona to the cold of Michigan.

- Sealers: Applied after curing, sealers protect the concrete surface from moisture penetration, staining, and abrasion, enhancing its lifespan and appearance.

- Safety Gear: Safety is always our top priority. We adhere strictly to OSHA guidelines, and a comprehensive guide to concrete safety is available from A guide to concrete safety from OSHA.

- Personal Protective Equipment (PPE): This includes hard hats, safety glasses, hearing protection, gloves, respirators (especially when cutting or mixing), and steel-toed boots. Ensuring our team is properly equipped protects them from the inherent hazards of concrete work.

Frequently Asked Questions about Sourcing Supplies

We understand that navigating concrete contractor supplies can sometimes feel overwhelming. Here are some common questions we hear, along with our insights.

How do I find concrete suppliers near me?

Finding reliable local suppliers is a cornerstone of efficient project management. Here’s how we typically go about it:

- Online searches: A quick search on Google Maps or specialized construction directories for “concrete suppliers near me” or “concrete contractor supplies in [your city/state]” will often yield a list of local options. We also check their websites for product lists and service areas.

- Local business directories: Chambers of Commerce or local building associations often maintain lists of businesses, including material suppliers.

- Industry associations: Organizations like the Associated General Contractors (AGC) or American Subcontractors Association (ASA) have local chapters. Their members often share recommendations for trusted suppliers.

- Word-of-mouth referrals: There’s no substitute for a recommendation from a fellow contractor. Ask peers, general contractors, or even local hardware store owners for their preferred suppliers. Their experiences can provide valuable insights into reliability and service.

What are the most common mistakes contractors make when ordering supplies?

Even experienced contractors can sometimes stumble when it comes to ordering concrete contractor supplies. We’ve learned from our own experiences and observations:

- Underestimating quantities: This is a classic. Running short on concrete mid-pour, or realizing you don’t have enough rebar, leads to costly delays, emergency orders, and often higher prices. Always double-check your calculations and add a small buffer.

- Ignoring lead times: Assuming all materials are readily available can be a mistake, especially for custom orders or specialty items. Always confirm lead times with your supplier and factor them into your project schedule.

- Not verifying material specifications: Ordering “cement” isn’t enough. You need to specify the type (e.g., Type I Portland cement), strength, and any admixtures. For rebar, specify grade and size. Getting the wrong material can compromise structural integrity.

- Forgetting accessory items: It’s easy to focus on the big-ticket items like concrete and rebar, but forgetting essential accessories like rebar caps, form ties, curing blankets, or even basic hand tools can bring a job to a halt. We always use a comprehensive checklist.

How can I save money on my concrete contractor supplies?

Every contractor aims to maximize profitability without compromising quality. Here’s how we approach saving money on concrete contractor supplies:

- Bulk purchasing: For frequently used items or large projects, buying in bulk almost always yields a better price per unit. Negotiate with your supplier for volume discounts.

- Building relationships for better pricing: Loyal customers often receive preferential treatment, including better pricing, extended credit terms, or priority delivery. Invest in a strong, long-term relationship with a few key suppliers.

- Reducing waste on-site: Proper planning, accurate measurements, and careful handling of materials minimize waste. Every bag of cement or length of rebar saved is money in your pocket.

- Optimizing delivery schedules: Consolidate your orders whenever possible to reduce the number of deliveries and associated fees. Planning ahead allows you to receive multiple items in a single, larger shipment, saving on transport costs.

Conclusion: Building a Strong Foundation with the Right Partner

As we’ve explored, concrete contractor supplies is vast and varied, but making the right choices is fundamental to your success. We’ve seen that understanding the different types of suppliers—from national chains to local distributors and online specialists—and knowing how to thoroughly evaluate them is key. Factors like product quality, inventory, delivery reliability, and customer service are not just conveniences; they are critical components of efficient and profitable construction.

The right concrete contractor supplies partner ensures your projects run smoothly, on time, and within budget, allowing you to focus on what you do best: building strong, lasting structures. By carefully vetting your suppliers and fostering strong relationships, you’re not just buying materials; you’re investing in the success and reputation of your business.

For strong, code-compliant rebar supports that save time and money, consider the #1 choice in America; Hercules Rebar Chairs. With over 14 million units sold, our iconic red rebar chairs are engineered for superior performance, ensuring your reinforcement stays exactly where it needs to be. We are committed to providing the foundational support you need for every pour. Learn more about our rebar footing support solutions and how we can support your next project.