The Unsung Heroes of Concrete Construction

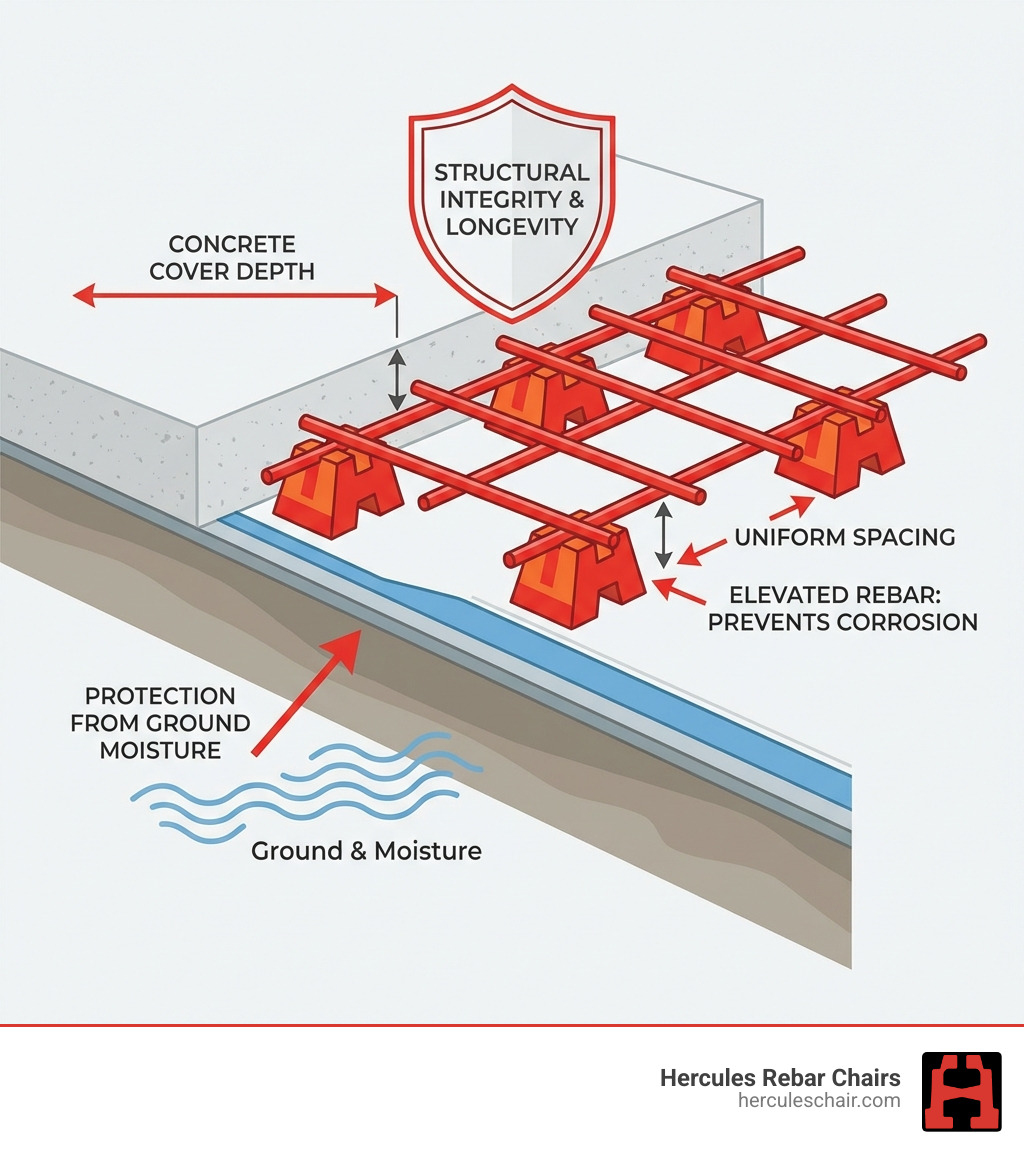

Concrete rebar support blocks are devices that lift and position reinforcing steel (rebar) at the correct height within concrete forms before pouring. They ensure proper concrete cover around the steel reinforcement, which protects against corrosion and maintains structural integrity.

Quick Reference: What Rebar Support Blocks Do

- Primary Function: Hold rebar off the ground or formwork at a precise height

- Key Benefit: Create uniform concrete cover (typically 10-100mm) around steel reinforcement

- Result: Prevent corrosion, extend structure lifespan, and meet building codes

- Common Types: Plastic chairs, slab bolsters, beam bolsters, and continuous supports

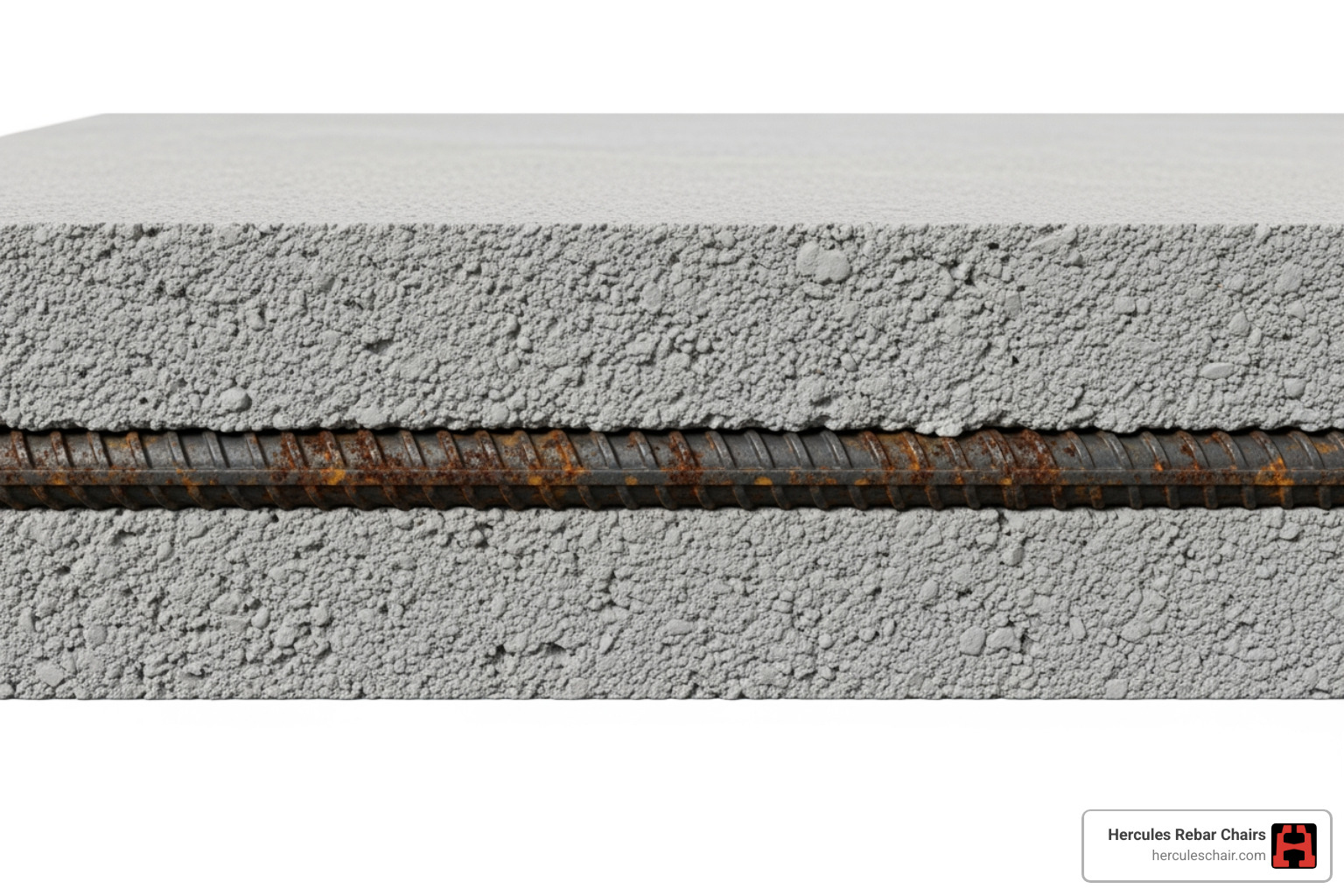

If you’ve ever watched rebar sink into the mud or settle to the bottom of a form during a concrete pour, you know the problem. Without proper support, your reinforcing steel ends up in the wrong place. And when rebar sits too close to the concrete surface, moisture reaches the steel, corrosion begins, and your structure’s lifespan gets cut short.

Rebar supports solve this problem. They’re simple devices that keep your steel exactly where your engineer specified it. Some look like small plastic chairs. Others are continuous wire supports that run the length of your pour. All of them serve the same critical purpose: maintaining the protective concrete cover that keeps your rebar from rusting.

The research is clear on this. Proper concrete cover is non-negotiable for structural longevity. Whether you’re pouring a slab-on-grade, forming up walls, or building a bridge deck, these small components make the difference between a structure that lasts decades and one that fails prematurely.

In this guide, we’ll break down everything you need to know about concrete rebar support blocks. You’ll learn which types work best for different applications, how to select the right specifications for your project, and the installation practices that ensure your rebar stays exactly where it needs to be.

Why Concrete Cover is Non-Negotiable for Structural Longevity

Imagine building a house, but forgetting to put a roof on it. That’s essentially what happens to your rebar when it doesn’t have adequate concrete cover. This protective layer of concrete around your reinforcing steel isn’t just a nicety; it’s a fundamental requirement for the structural integrity and longevity of any concrete structure.

Concrete cover is the distance between the surface of the concrete and the nearest reinforcing steel bar. Its primary function is multifaceted:

- Corrosion Protection: This is arguably the most critical role. Concrete is naturally alkaline, which creates a passive layer around the steel, protecting it from rust. However, if the rebar is too close to the surface, moisture, chlorides (from de-icing salts or marine environments), and other corrosive agents can penetrate the concrete and reach the steel. Once rust begins, it expands, causing the concrete to crack and spall, eventually compromising the structural integrity. Our concrete rebar support blocks ensure this vital barrier remains intact.

- Fire Resistance: In the event of a fire, concrete cover acts as an insulator, protecting the steel reinforcement from high temperatures. Steel loses its strength rapidly when heated, so adequate cover buys crucial time, maintaining the structural capacity of the building during an emergency.

- Structural Integrity and Load Transfer: The design of reinforced concrete relies on the composite action of steel and concrete working together. Proper cover ensures that the bond between the two materials is effective, allowing for efficient transfer of stresses and strains. Without it, the steel might not engage properly, leading to reduced load-bearing capacity.

- Crack Prevention: While rebar helps reduce cracking, consistent concrete cover also plays a role. It ensures the rebar is properly positioned to absorb and distribute tension caused when concrete expands and contracts due to climate variations. If rebar is too close to the surface, it can exacerbate cracking as the concrete moves.

The required concrete cover varies significantly depending on the structural element and its exposure to environmental factors. For instance, in walls, bars larger than No. 5 require 2 inches of cover when exposed to weather or in contact with the ground. For smaller bars (No. 5 and less), 1 1/2 inches is sufficient under these conditions. However, for interior wall faces not directly exposed to the ground or weather, a mere 3/4 inch is typically enough. Columns usually demand 1 1/2 inches of cover over spirals and ties, while beams and girders also require 1 1/2 inches to the nearest bars on all sides. For joists and slabs, 3/4 inch is common for surfaces not directly exposed to the ground or weather.

All these measurements are critical and are taken from the outside of the rebar to the face of the concrete. Our Rebar Placement Guide offers further insights into these crucial specifications. By precisely holding the rebar in place, concrete rebar support blocks directly contribute to meeting these cover requirements, ensuring your structure stands strong and lasts for generations.

A Breakdown of Concrete Rebar Support Blocks by Material and Type

Choosing the right concrete rebar support blocks is crucial. The world of rebar supports is diverse, with various materials and designs for specific applications. Understanding these differences is key to making the right choice.

Generally, rebar spacers fall into two main categories:

- Linear Spacers: Continuous supports that provide support along a line, ideal for long runs of rebar.

- Point Spacers: Individual supports, like chairs, that provide support at specific points for elevating bars or grids.

The primary raw materials are plastic, concrete, and metal, each with properties suited for different scenarios. You can find More info about our Products on our site.

Material Matters: Plastic vs. Fiber-Reinforced Concrete Supports

The choice between plastic and fiber-reinforced concrete supports balances cost, performance, and application.

Plastic Rebar Supports

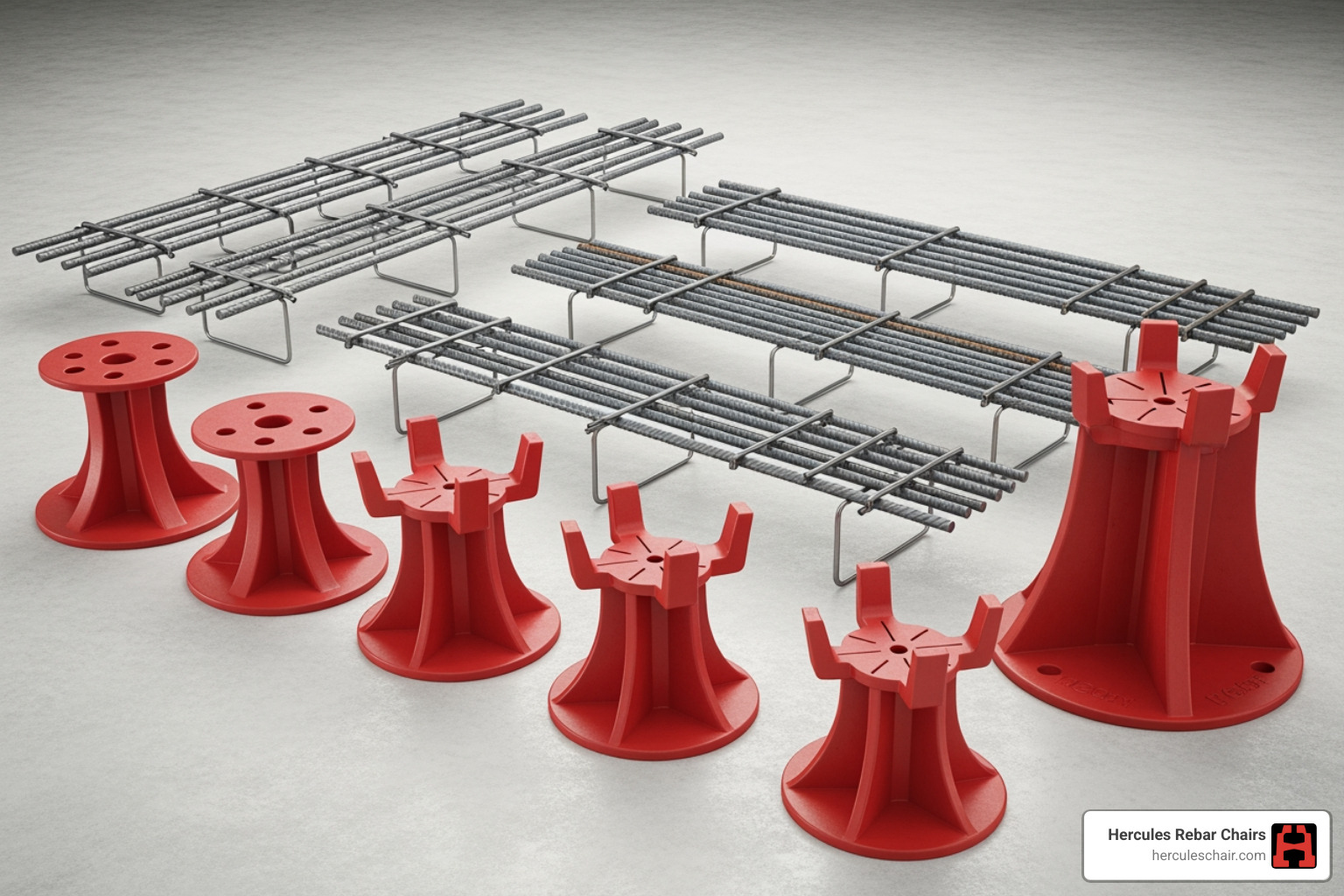

Plastic supports, like our Hercules rebar chairs, are popular for their low cost and ease of use. They are lightweight and easy to handle. Our iconic red chairs feature ribbed designs for excellent concrete adhesion, making them a go-to for many applications. However, plastic has limitations. Its thermal expansion is much higher than concrete’s, which can create gaps as temperatures change, allowing moisture to cause corrosion. Plastic can also melt at high temperatures, a concern for fire-rated assemblies.

Fiber-Reinforced Concrete Supports

Conversely, concrete spacers, made from extruded fiber-reinforced concrete, offer superior material compatibility. They bond seamlessly with the pour, preventing gaps from thermal expansion. This maintains material integrity and improves water tightness. Fiber-reinforced concrete also improves the spacers’ crack resistance and durability. They are favored for heavy-weight applications, projects with high fire safety requirements (like tunnels), and pre-cast systems. Research into the Characterization of cement-based spacers highlights their benefits.

Form and Function: Common Types of Concrete Rebar Support Blocks

The variety of concrete rebar support blocks reflects the diverse needs of concrete construction. Each type is engineered for specific functions. Here are some common types:

- Individual Rebar Chairs (Point Spacers): Our Hercules rebar chairs lift individual rebar or mesh to create uniform cover. They are lightweight, easy to install, and ideal for slabs and footings. Our Solo Chairs are available in heights from 3″ to 18″.

- Castle Chairs: These provide stable elevation for rebar in pours like slabs and driveways. Their wide base prevents sinking into soft ground. Our Castle Chairs offer cover heights from 1-1/2” to 6-1/4”.

- Slab Bolsters: These continuous wire supports are for the bottom layer of steel in slabs. They come in 5-foot lengths and ensure consistent placement. Heights range from 3/4″ to 7″.

- Slab Bolster Uppers: These support an upper layer of rebar or are used on soft surfaces. A runner wire adds stability. Heights range from 3/4″ to 5″.

- Beam Bolsters: Similar to slab bolsters but designed for beams, with closer leg spacing for concentrated loads. Heights range from 3/4” to 4”.

- Beam Bolster Uppers: These support upper rebar levels in beams, often with a runner wire for stability.

- Continuous Support (Zig-Zags): Heavy-duty linear supports for thick applications like highways and bridge decks, providing exceptional stability. Cover heights range from 2” to 16”.

- Continuous High Chairs: Robust continuous supports that hold steel on soft surfaces or multiple rebar layers. They accommodate cover heights from 2” to 30”.

- Snap-On Mesh Chairs: High-strength, heat-resistant chairs used with mesh sheets, offering heights from 1” to 6”.

- Footer Stands: Specialized supports like our 3-Bar Footer Stand lift multiple bars in footings, ensuring perfect positioning.

Choosing the right support is crucial for any project design, from simple slabs to complex rebar mats. Each design serves a purpose, and we can help you select the best fit.

How to Select the Right Rebar Support for Your Project

Selecting the correct concrete rebar support blocks isn’t a one-size-fits-all decision. It’s a critical step that impacts the structural integrity and longevity of your concrete project. Think of it like choosing the right shoes for a marathon versus a sprint—each requires specific features for optimal performance. Our goal is to empower you to make informed decisions for your job site.

When we approach a project, we consider several key factors:

- Application: What kind of concrete element are you pouring? (Slab-on-grade, liftd slab, beam, column, wall, footing, etc.)

- Environment: Will the concrete be exposed to weather, corrosive elements (like salts or marine air), or seismic activity?

- Structural Requirements: What are the specified concrete cover depths, rebar sizes, and load capacities?

- Sub-base Material: Is the support resting on a vapor barrier, compacted earth, gravel, or a soft form surface?

Key Specifications to Consider

To ensure we’re getting the job done right, we carefully evaluate the specifications of each rebar support:

- Height Specification (Cover Depth): This is paramount. The support’s height directly dictates the concrete cover over the rebar. Heights can range significantly, from 3/4″ for thinner slabs to 30″ for deep foundations or multi-layer rebar cages. For instance, our Slab Bolster Uppers are available in heights from 3/4″ to 5″, while individual Solo Chairs can go from 3″ to 18″. Always match the support height to your project’s engineered cover requirements.

- Material Choice: As we discussed, plastic, fiber-reinforced concrete, and metal (steel) are the main options. The choice depends on the environment and structural demands. Plastic is lightweight and economical for many applications, while concrete offers superior material compatibility. Metal supports provide robust strength.

- Coating Options: For steel supports, coatings are crucial in specific environments.

- Plain Steel: Suitable for interior, dry applications where corrosion is not a major concern.

- Epoxy Coated: Offers improved corrosion resistance, ideal for projects exposed to moisture or mild corrosive agents.

- Galvanized: Provides another layer of protection against rust, often used in outdoor or damp conditions.

- Plastic-dipped/tipped feet: For steel supports, these prevent rust marks on exposed concrete surfaces and protect vapor barriers.

- Length: Continuous supports like slab bolsters and beam bolsters come in standard lengths, often 5 feet. This is important for efficient layout and coverage on larger pours.

- Base Design: The design of the support’s base is critical for stability, especially on varying sub-base materials.

- Wide Base: Supports like our Castle Chairs with a wide base prevent sinking into soft ground or insulation.

- Runner Wires: Slab Bolster Uppers and Beam Bolster Uppers often have runner wires spot-welded to their feet, providing a continuous contact surface for stability on soft forms or lower rebar layers.

- 4-Point Contact: Individual bar chairs with a 4-point contact base offer stability for lighter steel in slab/deck construction.

For a comprehensive overview of our product specifications, check out our Data Sheet.

Matching the Support to the Application and Environment

The specific characteristics of your project and its environment will heavily influence your selection:

- Slabs-on-Grade: For slabs poured directly on the ground, especially with a vapor barrier, we recommend supports with a wide base or plastic-tipped feet to prevent puncturing the membrane and minimize rust staining. Our Vapor Barrier Mat can also be used to provide a stable, protective base for your supports.

- Liftd Slabs and Decks: For these, individual chairs or continuous high chairs are common, depending on the rebar layout and load. Metal supports, potentially epoxy-coated, might be preferred for durability.

- Walls and Columns: Vertical applications often use specialized spacers that attach to the rebar and bear against the formwork, ensuring consistent cover on all sides.

- Corrosive Environments: If your project is near saltwater, uses de-icing salts, or faces other corrosive elements, selecting supports made from stainless steel, chromium steel, or those with heavy epoxy or galvanized coatings is crucial to prevent premature corrosion. This is especially vital in places like our coastal states, where bridges and other infrastructure are constantly battling the elements. Projects like the Design and Construction of Segmental Concrete Bridges for Service Life of 100 to 150 Years emphasize the importance of material selection in such environments.

- Seismic Zones: In areas prone to high seismic activity, the structural integrity of every component is scrutinized. Using robust, high-quality concrete rebar support blocks that maintain precise rebar positioning and cover is essential to ensure the structure can withstand dynamic forces.

By carefully considering these factors, we ensure that the concrete rebar support blocks we choose not only meet the immediate needs of the pour but also contribute to the long-term strength and resilience of the entire structure.

Installation Best Practices for Concrete Rebar Support Blocks

Even the best concrete rebar support blocks are only as good as their installation. Proper placement is crucial to ensure that the rebar stays exactly where the engineer intended, providing the correct concrete cover and maximizing the structural integrity of your project. We’ve seen it all, and we know that a little attention to detail during installation saves a lot of headaches (and money) down the line.

Here are our best practices for installing rebar supports:

- Follow the Design Documents: Always, always, always refer to your project’s blueprints and specifications. These documents will dictate the required concrete cover, rebar spacing, and often, the specific type and placement of supports.

- Even Spacing is Key: Distribute your supports evenly across the rebar mat or cage. This prevents localized sagging or displacement of the rebar, especially under the weight of foot traffic or the fresh concrete. The Concrete Reinforcing Steel Institute (CRSI) and American Concrete Institute (ACI) standards provide guidelines for spacing, typically recommending closer spacing for heavier rebar or thicker slabs.

- Stability on the Sub-base: Ensure the supports are placed firmly on the sub-base or formwork. If you’re working on a soft surface (like compacted earth or insulation), use supports with a wide base or continuous runner wires to prevent them from sinking. Our Footer Stand Placement Guide offers detailed instructions for these critical elements.

- Secure the Rebar: While many supports cradle the rebar, some designs allow for the rebar to be tied or clipped into place. This is especially important for vertical elements like walls and columns to prevent movement during the pour.

- Protect Vapor Barriers: If you’re using a vapor barrier, select supports with plastic-tipped feet or a broad, flat base to avoid puncturing the membrane. A damaged vapor barrier can lead to moisture issues in your slab.

Tips for Specific Support Types and Designs

Different concrete rebar support blocks require slightly different installation approaches:

- Individual Chairs (e.g., Hercules Rebar Chairs): Place these chairs at regular intervals, typically following a grid pattern, to support the rebar. Ensure each rebar intersection is adequately supported or that the spans between supports are not excessive, which could lead to deflection. For lighter rebar, a wider spacing might be acceptable, but for heavier bars or higher loads, more frequent placement is needed.

- Slab Bolsters and Beam Bolsters: These continuous supports are laid directly on the formwork or lower rebar layer. When supporting one layer of steel above another, place the bolster so its runner wires are perpendicular to the lower rebar. Then, lay the upper layer of rebar perpendicularly on the bolster’s top supporting wire. This creates a stable, liftd plane. Their locking ends can create a durable connection when joining multiple bolster sections.

- Multi-Layer Rebar Mats (Using High Chairs): For projects requiring multiple layers of rebar, high chairs are invaluable. They are designed to span and straddle the lower rebar, cradling the upper layer at the correct elevation. This ensures precise vertical spacing between rebar layers, which is crucial for structural performance.

- Curved Surfaces: For curved designs, continuous supports can often be gently bent to follow the contour, or individual chairs can be strategically placed to maintain the curve. The key is to ensure consistent cover throughout the curve.

To help you plan and execute your rebar support placement efficiently, we offer the Hercules Rebar Chair Estimator. This tool can assist in determining the right quantity and spacing for your project, saving you time and ensuring compliance. A well-supported rebar cage is a robust foundation for a long-lasting concrete structure.

Frequently Asked Questions about Rebar Supports

We hear a lot of questions about concrete rebar support blocks, and for good reason! They might seem like small components, but their role is mighty. Let’s tackle some of the most common inquiries we get.

How many rebar chairs do I need for my project?

This is a question we get all the time, and the answer, like many things in construction, is “it depends!” The exact number of rebar chairs or supports you need will vary based on several factors:

- Rebar Size and Weight: Heavier, larger diameter rebar will require more frequent support to prevent sagging.

- Slab Thickness/Concrete Cover: Thicker slabs or those requiring greater concrete cover often necessitate taller, and sometimes more robust, supports.

- Load on the Rebar Before Pour: Consider the weight of workers, concrete pumps, and other equipment that might be on the rebar mat before the pour. More supports provide better stability.

- Spacing Guidelines: Industry standards and engineering specifications will provide minimum spacing requirements. A general rule of thumb for slabs might be to space individual chairs every 2-3 feet in both directions, but always consult your project’s engineered drawings.

To simplify this process, our Hercules Rebar Chair Estimator is a fantastic tool that can help you calculate the approximate number of chairs needed for your specific project dimensions. It takes the guesswork out of ordering and helps you save time and money.

Can I use broken bricks or rocks instead of proper supports?

Absolutely not! While it might seem like a clever way to save a few bucks, using broken bricks, rocks, scraps of wood, or any other makeshift material as rebar supports is a recipe for disaster. Here’s why we strongly advise against it:

- Inconsistent Height: Makeshift supports are rarely uniform in height, leading to uneven concrete cover. This compromises the rebar’s protection and the slab’s structural integrity.

- Absorb Moisture: Porous materials like bricks or wood will absorb moisture from the wet concrete, creating localized areas of weakness and potential pathways for water intrusion.

- Create Weak Points: These foreign objects don’t bond with the concrete like proper supports (especially fiber-reinforced concrete spacers) do. They can create voids or cold joints, leading to cracks and structural weaknesses.

- Risk of Corrosion: If the makeshift support is too permeable, it can allow corrosive elements to reach the rebar, accelerating rust.

- Fails Inspection: Building inspectors are well aware of this common shortcut and will likely fail your project, costing you more in rework and delays than you would have saved on proper supports.

Using purpose-built concrete rebar support blocks is a non-negotiable best practice for quality construction.

What happens if I don’t use any rebar supports?

Skipping rebar supports is akin to setting your concrete project up for premature failure. The consequences can be severe and costly:

- Rebar Sinks: Without supports, the weight of the rebar itself, combined with the pressure of the wet concrete, will cause the rebar to sink to the bottom of the formwork.

- No Concrete Cover: If the rebar is resting on the ground or formwork, it has little to no concrete cover beneath it. This exposes the steel directly to moisture from the ground or environmental elements.

- Corrosion Risk: Exposed rebar will rust quickly. As rust expands, it creates internal pressure that causes the concrete to crack, spall, and delaminate.

- Spalling and Delamination: The concrete surface will begin to flake off, exposing more rebar and accelerating the decay process.

- Structural Failure: The entire structural integrity of the concrete element is compromised. The rebar cannot perform its intended function of resisting tensile forces if it’s not properly encased in concrete. This leads to reduced strength and a significantly shorter lifespan for the structure.

- Cracking: Without the rebar properly positioned to distribute tension, the concrete will be much more prone to cracking as it cures and experiences thermal expansion and contraction.

Not using concrete rebar support blocks undermines the very purpose of reinforced concrete, turning what should be a durable, long-lasting structure into a fragile one. It’s a small investment that yields massive returns in structural integrity and peace of mind.

Conclusion: Building a Stronger, More Durable Structure

In the grand scheme of a concrete construction project, concrete rebar support blocks might seem like minor details. However, as we’ve explored, these unsung heroes play an absolutely vital role in the structural integrity and longevity of every pour. From ensuring precise concrete cover to protecting against corrosion, enhancing fire resistance, and preventing premature cracking, their contribution is immeasurable.

By carefully selecting the right type of support—whether it’s our robust plastic rebar chairs, versatile slab bolsters, or specialized footer stands—and adhering to best installation practices, we ensure that your rebar stays exactly where your engineer specified it. This attention to detail isn’t just about meeting code compliance; it’s about building structures that stand the test of time, resisting the elements and the wear and tear of daily use for decades to come.

At Hercules Rebar Chairs, we pride ourselves on being America’s #1, with over 14 million units sold, helping contractors save time and money while achieving superior results. Our commitment to quality and innovation means you can trust our products to keep your rebar up, ensuring your concrete structures are as strong and durable as possible.

Don’t underestimate the power of proper rebar support. It’s a small investment that yields massive returns in structural integrity, longevity, and ultimately, your reputation. Ready to equip your next project with the best? Buy Rebar Chairs directly from us or find a retailer near you!