Why Accurate Rebar Calculation is Crucial

A rebar slab calculator helps you determine the exact quantity, length, and weight of reinforcement steel needed for your concrete pour. Here’s what you need to know:

Key Inputs Required:

- Slab dimensions (length, width, depth)

- Rebar size (#3, #4, #5, etc.)

- On-center spacing (typically 18-24 inches)

- Concrete cover (usually 2-3 inches)

- Lap splice length and waste factor

What It Calculates:

- Total linear feet of rebar needed

- Number of rebar pieces required

- Total steel weight

- Number of stock bars to order

Getting your rebar calculations wrong can cost you serious money and time. Order too little, and you’re making emergency runs to the supplier mid-pour. Order too much, and you’re eating the cost of excess material that sits in your yard.

But here’s the bigger issue: incorrect rebar placement can lead to serious concrete structural failures. Concrete handles compression well, but it’s weak under tension. That’s where rebar comes in—it can boost concrete’s resistance to failure by several times.

For contractors, accurate calculations mean better bids, fewer change orders, and jobs that stay on schedule. Research shows that reinforced concrete slabs last much, much longer than unreinforced ones, making proper calculation not just about today’s pour, but about the structure’s lifetime performance.

Whether you’re pouring a residential patio with #4 rebar at 18-inch spacing or a commercial foundation with tighter tolerances, understanding how to calculate your rebar needs correctly is fundamental to the job.

Understanding the Key Inputs for a Rebar Slab Calculator

When we talk about using a rebar slab calculator, we’re really talking about a powerful tool that simplifies a complex estimation process. To get accurate results, we need to provide it with precise information about our project. Think of it like baking a cake – if you don’t use the right ingredients in the right amounts, you won’t get the desired outcome. The key inputs for any rebar calculator include your slab’s dimensions, the size and spacing of the rebar, the concrete cover, and factors like lap splices and waste.

Slab Dimensions and Concrete Cover

The foundation of any rebar calculation starts with the physical size of your concrete slab. We need to input the length and width of the area to be reinforced, typically measured in feet. For irregular shapes, we’ll break the area down into smaller, manageable geometric forms, calculate each, and then combine them for a total. We also need the slab thickness or depth, usually in inches, as this impacts the overall volume of concrete and, indirectly, the placement of our rebar.

Now, let’s talk about concrete cover. This is the thickness of concrete between the rebar and the outside surface of the slab. Why is it so important? Concrete cover serves two main purposes:

- Corrosion Protection: It shields the steel rebar from moisture and chemicals, preventing rust and subsequent expansion that can crack the concrete.

- Fire Resistance: It helps protect the rebar from high temperatures during a fire, maintaining the structural integrity of the slab for longer.

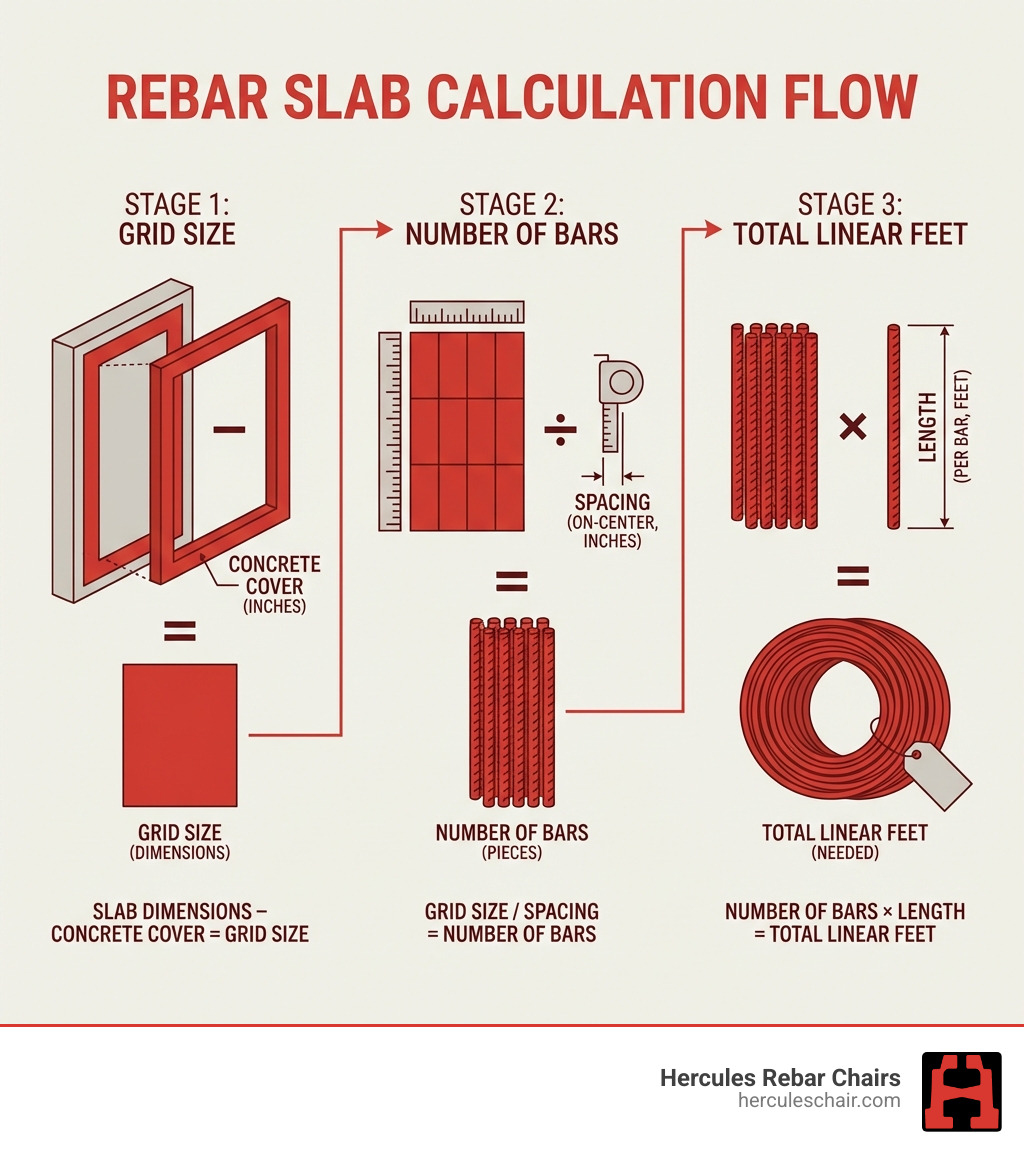

How does concrete cover affect our rebar calculation? A rebar slab calculator accounts for concrete cover by subtracting it from the overall slab dimensions. For example, if we have a 10-foot slab and need 2 inches of cover on each side, our effective rebar grid will be 9 feet 8 inches wide, not 10 feet. Common cover values are 2 inches for slab bottoms and walls, and 3 inches for footings. By accurately calculating this internal “grid size,” we ensure the rebar is placed where it provides the most structural benefit and is adequately protected.

Rebar Sizes, Spacing, and Weight

The choice of rebar isn’t one-size-fits-all. Rebar sizes are designated by numbers, where each number represents the bar’s diameter in eighths of an inch. So, a #4 rebar is 4/8″ (or 1/2″) in diameter, while a #8 is a full inch.

Here’s a quick look at common rebar sizes and their typical uses:

| Rebar Size | Diameter (inches) | Approx. Weight per Foot (lbs) | Typical Uses |

|---|---|---|---|

| #3 | 3/8 | 0.376 | Light residential slabs, sidewalks, small patios |

| #4 | 1/2 | 0.668 | Driveways, residential slabs, foundations, footings |

| #5 | 5/8 | 1.043 | Heavy residential slabs, commercial floors, columns |

| #6 | 3/4 | 1.502 | Industrial slabs, heavy-duty foundations, structural |

Note: Weights are approximate and can vary slightly by manufacturer.

Rebar spacing refers to the distance between the center of one rebar to the center of the next, known as “on-center spacing.” For flat slabs like driveways and patios, spacing is typically 18 to 24 inches. However, for footings or slabs bearing heavier loads, a tighter spacing of 12 inches is often specified to meet building codes. The rebar slab calculator will use this spacing to determine how many bars are needed in each direction.

The choice of rebar size and spacing directly impacts the total weight and cost of the rebar. Finer spacing means more bars, which increases the total linear footage and, consequently, the total weight and cost. Similarly, using a larger rebar size (e.g., #5 instead of #4) significantly increases the weight per linear foot, even if the spacing remains the same. For instance, going from #4 to #5 rebar increases the unit weight by approximately 56%! This is why careful consideration of both size and spacing is crucial for both structural integrity and budget management.

Factoring in Laps, Waste, and Stock Lengths

Concrete slabs often exceed the length of a single piece of rebar, which means we need to join them together. This is where lap splices come in. A lap splice is the length by which two pieces of rebar must overlap to safely transfer tension from one bar to the next. A common rule of thumb for lap splices is to overlap by at least 40 times the bar’s diameter. So, for a #4 (1/2-inch diameter) rebar, a lap splice would be 40 * 0.5 inches = 20 inches. Your project specifications and local codes will dictate the exact lap development length required for your specific conditions.

Rebar is commonly available in standard stock lengths such as 20, 30, 40, and 60 feet in the United States. When your slab dimensions are longer than these stock lengths, the rebar slab calculator will automatically factor in the necessary lap splices to ensure continuous reinforcement. Interestingly, if your stock length is equal to or greater than the span in a particular direction, no laps are needed in that direction, which can reduce both lap length and total weight.

Finally, we must account for waste. No construction project is perfectly efficient, and rebar is no exception. Cuts, mismeasurements, and small off-cuts mean we’ll always use a little more material than the theoretical calculation. We generally recommend ordering 10% additional material to account for these overlaps, cutoffs, and general waste. Some contractors might use a smaller waste factor, like 2-5%, for very simple take-offs, but a 10% buffer is a safe bet to prevent shortages and unexpected trips to the supplier. For more on rebar’s purpose and its indispensable role in construction, you can read our detailed guide: More on rebar’s purpose.

How to Use a Rebar Calculator: A Step-by-Step Guide

Using a rebar slab calculator isn’t just about punching numbers; it’s about making informed decisions for your project. This tool helps us move from vague estimates to precise material takeoffs, preventing both costly over-ordering and frustrating under-ordering. Let’s walk through the process.

Step 1: Gather Your Project Dimensions and Specs

Before we even touch a calculator, we need to gather all the critical information for our project. This is the “measure twice, cut once” phase.

- Measure the Area: Accurately measure the length and width of your concrete pour area. If it’s an irregular shape, break it down into simple rectangles or squares and measure each section. Use consistent units (e.g., all feet or all inches).

- Determine Slab Thickness: Know the exact depth of your concrete slab, typically in inches.

- Choose Rebar Size: Based on the load-bearing requirements and the type of project (residential patio, commercial foundation, etc.), select the appropriate rebar gauge. As we discussed, #3 to #5 rebar is common for residential work, while industrial projects might need #6 or thicker.

- Decide on Spacing: Determine your desired on-center spacing for the rebar grid. This could be 12, 18, or 24 inches, depending on the project’s demands.

- Identify Concrete Cover: Know the required concrete cover for your project, usually 2 or 3 inches, to protect the rebar.

- Check Local Code Requirements: This is non-negotiable! Always consult your local building codes and any project-specific engineering plans. These documents will specify minimum rebar sizes, spacing, and lap splice lengths, especially for structural elements like foundations. We don’t want to get caught having to redo work because we didn’t check the rules.

Step 2: Using an Online Rebar Slab Calculator

With all our project data in hand, we’re ready to use the rebar slab calculator. Most online calculators are very user-friendly, guiding us through the inputs.

Let’s imagine we’re planning a concrete patio that’s 20 feet long and 15 feet wide, with a 4-inch thickness. We’ve decided to use #4 rebar with an 18-inch on-center spacing and a 2-inch concrete cover.

Here’s how we’d typically enter the data:

- Slab Length: 20 feet

- Slab Width: 15 feet

- Slab Thickness: 4 inches (though this might not be a direct input for rebar, it’s good to have)

- Rebar Size: #4

- Rebar Spacing: 18 inches (on-center)

- Concrete Cover (Edge Clearance): 2 inches

- Lap Splice Factor: 40 times diameter (if applicable, the calculator might handle this automatically for dimensions exceeding stock lengths)

- Waste Factor: 10% (as a buffer)

The calculator will then process these inputs. It will first determine the effective rebar grid dimensions by subtracting the concrete cover from the slab’s length and width. For our 20′ x 15′ slab with 2″ cover, the rebar grid would be 19′ 8″ x 14′ 8″. Then, it will calculate the number of bars needed in each direction based on the spacing, typically adding one extra bar to ensure the far edge is satisfied.

Step 3: Understanding the Calculator’s Output

Once we hit “calculate,” the rebar slab calculator will provide us with a detailed breakdown of our rebar needs. These outputs are crucial for ordering materials and planning our installation.

Here are the key metrics we’ll typically see:

- Total Linear Feet: This is the total length of rebar required for the entire slab, including any calculated lap splices.

- Total Steel Weight: This figure tells us the total weight of the rebar in pounds, which is important for transportation and cost estimation.

- Number of Rebar Pieces: The calculator will break down how many individual bars are needed for both the length and width directions of the grid.

- Number of Stock Bars: Based on standard rebar lengths (e.g., 20 ft), the calculator estimates how many full stock bars we need to purchase. This helps us visualize our order.

With these numbers in hand, we can create an accurate material order list. We’ll take the “Number of Stock Bars” and, as a best practice, add our 10% waste factor to that total. This ensures we have enough material for any unexpected cuts or overlaps and avoids costly project delays. This precise calculation process prevents us from ordering too much material, which ties up capital, or too little, which brings our project to a grinding halt.

Beyond the Numbers: Proper Placement and Safety

Calculating rebar is a critical first step, but the job isn’t done until the rebar is correctly placed and the concrete is poured safely. Even the most accurate calculations are useless if the rebar isn’t installed properly.

The Importance of Rebar Placement and Supports

Once we’ve calculated our rebar needs, the next challenge is ensuring it’s positioned correctly within the concrete slab. Rebar isn’t meant to sit directly on the ground; for effective reinforcement, it must be located in the middle or upper-third of the slab’s thickness. This strategic placement allows the rebar to absorb tensile forces effectively, preventing cracks and providing structural support.

This is where rebar chairs (also known as concrete supports) become indispensable. These small, sturdy devices hold the rebar grid at the precise height required, ensuring it stays in place during the concrete pour. Without them, the rebar could sink to the bottom, rendering it ineffective. At Hercules Rebar Chairs, we pride ourselves on manufacturing strong, reliable rebar chairs that are America’s #1 choice, with millions sold. Our distinctive red chairs ensure that your rebar stays exactly where it needs to be, helping you achieve code compliance and a structurally sound slab. For a deeper dive into how to correctly position your rebar, Read our detailed Rebar Placement Guide. If you’re ready to secure your rebar with the best, you can Buy Rebar Chairs directly from us.

Safety First: Working with Rebar and Concrete

Working with rebar and concrete involves inherent risks, and safety should always be our top priority. We always ensure our team wears appropriate Personal Protective Equipment (PPE), including hard hats, safety glasses, gloves, and sturdy work boots.

Here are some specific safety considerations:

- Handling Sharp Edges: Rebar often has sharp ends and can be cumbersome. We take care to handle it with gloves, avoid walking too close to exposed ends, and cap any protruding rebar to prevent impalement hazards.

- Cutting Hazards: When cutting rebar, whether with a grinder or rebar cutter, sparks and flying debris are a concern. We ensure eye and face protection are always worn.

- Concrete Dust Risks: Perhaps one of the most overlooked hazards is the dust generated when cutting concrete, blocks, or even stone. This dust can contain crystalline silica, and prolonged exposure can lead to silicosis, a serious and irreversible lung disease. The best practice is to cut wet to suppress dust, or if dry cutting is unavoidable, to wear a proper respirator. As the saying goes, “Silicosis Sucks!” Always prioritize dust control to protect your long-term health. For more information on the dangers, refer to the Health risks of silica dust.

By following these safety protocols, we protect ourselves and our crew, ensuring that our projects are not only structurally sound but also completed without incident.

Frequently Asked Questions about Rebar Calculation

Even with a reliable rebar slab calculator, some questions often arise, especially for those new to concrete reinforcement or tackling more complex projects. Let’s address some common queries and clarify advanced concepts.

What’s the difference between ‘exact’ and ‘equal’ spacing?

When using a rebar slab calculator, you might encounter options for “exact spacing” versus “equal spacing.” Understanding the distinction is key to achieving your desired rebar layout.

- Exact Spacing: This method calculates bars at exactly the entered center-to-center distances, starting from one end of the effective rebar grid. The calculator will then adjust the space for the very last bar or the middle space to fit the remaining length. This means most of your rebar will be at your precise target spacing, but there might be one slightly smaller or larger space at an edge or in the middle. This is often indicated by the calculator marking the adjusted space in red.

- Equal Spacing: In contrast, the equal spacing method adjusts all spaces evenly across the entire length or width of the effective rebar grid. The calculator will determine the closest spacing (either slightly less than or equal to your target spacing) that allows all bars to be placed with uniform gaps between them. This results in a cleaner, more symmetrical layout, which can sometimes be preferred for aesthetic or practical reasons, even if the exact target spacing isn’t met precisely.

The choice between the two often depends on project specifications or personal preference, but both methods ensure full coverage of the slab.

Can I use a rebar slab calculator for footings or walls?

Yes, many advanced rebar slab calculator tools, especially online versions, are designed to estimate rebar for various concrete elements beyond just flat slabs. You’ll often find options for “Fast Takeoffs for Slabs, Footings & Walls.” While the underlying principles of calculating linear footage and weight remain similar, the inputs and specific requirements will differ.

For instance:

- Footings: Footings typically require tighter rebar spacing than general slabs, often no more than 18 inches apart to meet building codes for foundations. The calculator will account for the different dimensions and potentially different cover requirements.

- Walls: Concrete walls will have both horizontal and vertical rebar. A calculator for walls would require inputs for wall height, length, thickness, and separate spacing for horizontal and vertical bars, as well as specific cover values (e.g., 2 inches for walls).

While these calculators provide material quantity estimates, they generally do not perform structural analysis. The appropriate rebar size and spacing for load-bearing footings or walls depend heavily on the loads they will bear and must be specified by a qualified structural engineer. Use the calculator for material takeoffs, but always defer to engineering plans for design specifics.

When should I consult a structural engineer?

This is a crucial question, and the answer is simpler than you might think: when in doubt, or when the structure is load-bearing. While a rebar slab calculator is an excellent tool for estimating material quantities for straightforward projects like residential patios or sidewalks, it has limitations.

We should always consult a structural engineer in the following situations:

- Load-Bearing Structures: Any concrete slab or element that will support significant weight, such as a foundation for a house, a garage slab, a commercial floor, or a retaining wall, absolutely requires a structural engineer’s input. They will design the rebar layout, size, and spacing based on anticipated loads, soil conditions, and specific building codes.

- Complex Designs: Slabs with unusual shapes, multiple layers of rebar, integrated beams, or those subject to unique environmental conditions (e.g., seismic zones, heavy machinery vibration) demand professional engineering.

- Local Code Mandates: Many local building codes explicitly require engineered plans for certain types of concrete construction. Always check with your local building department before starting any significant project.

- Unfamiliarity or Uncertainty: If you’re unsure about the correct rebar size, spacing, or placement for your project, or if the consequences of failure are high, consulting an engineer is the safest and most responsible course of action.

A rebar slab calculator is a material estimation tool. A structural engineer is a design professional whose expertise ensures the safety and longevity of your concrete structure. They transform the theoretical into a safe, buildable reality.

Get an Accurate Estimate for Your Rebar Supports

We’ve covered a lot of ground, from understanding the inputs of a rebar slab calculator to the nuances of rebar placement and the importance of safety. The ultimate goal is to complete our concrete projects with confidence, knowing we’ve used the right materials, in the right quantities, and installed them correctly.

Accurate rebar quantity calculations are the first step in successful project planning. But just as important is ensuring that rebar stays precisely where it’s designed to be. That’s where high-quality rebar supports become invaluable. They prevent rebar from sinking during the pour, ensuring proper concrete cover and maximum structural integrity.

At Hercules Rebar Chairs, we understand the critical role our products play in your projects across the USA. Our strong, red rebar chairs are easily identifiable and designed to save you time and money by ensuring code compliance and preventing costly structural failures. With millions of units sold, we’re proud to be America’s #1 choice for rebar supports.

To help you get an even more precise estimate for the supports you’ll need, we invite you to use our specialized tool. Take the guesswork out of your next project and ensure your rebar is perfectly positioned. Use our free Hercules Rebar Chair Estimator today!