Why Concrete Mesh Support Chairs Matter for Every Pour

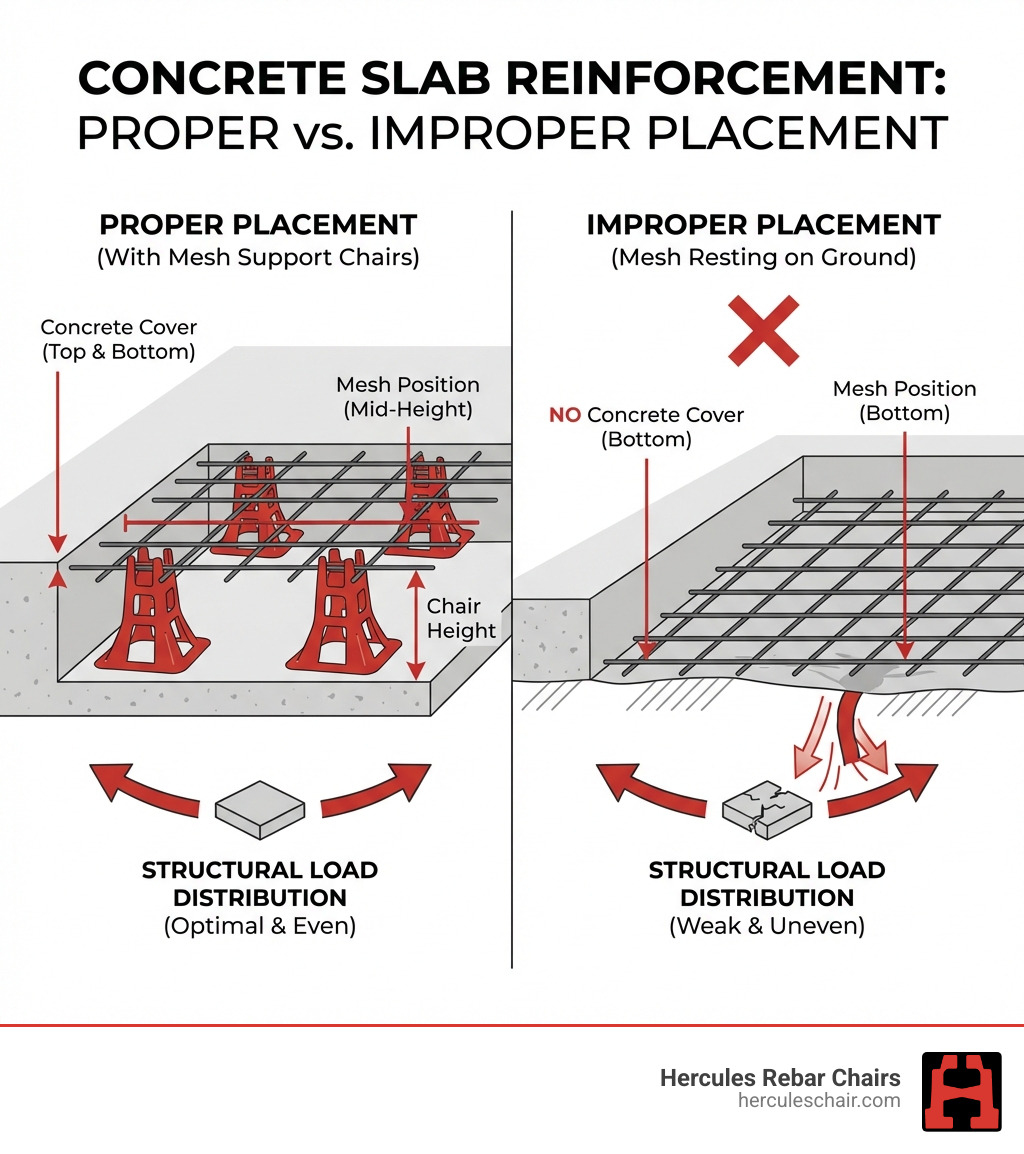

Concrete mesh support chairs are small but critical devices that hold wire mesh at the correct height within a concrete slab, ensuring the reinforcement sits in the center of the pour for maximum structural strength. Without proper support, your wire mesh sinks to the bottom during the pour, leaving your slab weak and prone to cracking.

Quick Answer: What Are Concrete Mesh Support Chairs?

- Purpose: Lift wire mesh reinforcement to the proper height within concrete slabs

- Function: Keep mesh positioned at mid-height during the pour for optimal structural integrity

- Design: Snap onto wire intersections and stay in place during concrete placement

- Result: Prevent mesh from sinking, ensure proper concrete coverage, eliminate weak spots

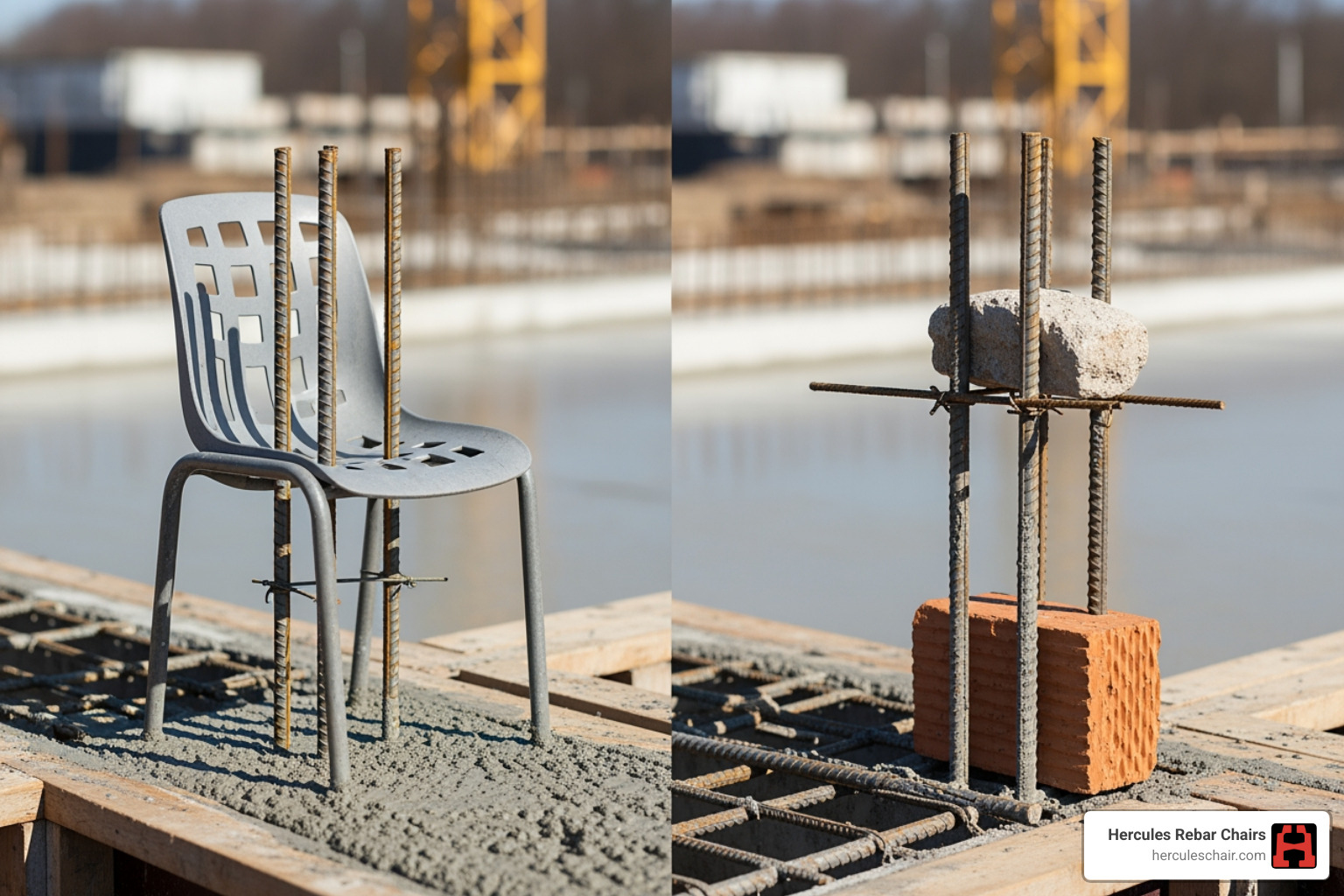

If you’ve ever poured a patio, driveway, or garage slab, you know the frustration of watching wire mesh sink into the subsurface or dealing with makeshift supports that shift during the pour. Many contractors still use bricks, rocks, or scrap materials to prop up their reinforcement—but these methods create inconsistent support heights, can puncture vapor barriers, and often require extra labor to adjust mesh position during the pour.

Mesh chairs solve these problems. They snap firmly onto wire intersections, provide stable support on grade, and even allow you to walk on the mesh during installation without permanent damage. The mesh deflects when stepped on, then springs right back into position.

According to the research, one contractor with 32 years of experience found that mesh chairs made it easy to “get wire up in slabs” and significantly reduced the need for constant supervision. Another contractor preparing a basement floor pour reported that the chairs “made the process easy” and allowed walking on the mesh “without issue.”

This guide will show you how to choose the right mesh chairs for your project, install them correctly, and ensure your concrete work meets code while saving time and labor.

Why Use Mesh Chairs? The Benefits Over Bricks and Blocks

When it comes to concrete construction, the seemingly minor detail of how you support your reinforcement mesh can make all the difference between a durable, long-lasting slab and one prone to cracks and failure. We’ve all seen, or perhaps even used, improvised methods to prop up wire mesh. But as experts in concrete supports, we can tell you that these shortcuts often create more problems than they solve. This is where engineered concrete mesh support chairs truly shine.

Our primary goal with any concrete pour is to achieve optimal structural integrity. This means ensuring that the wire mesh, which provides tensile strength, is perfectly positioned within the concrete. When the mesh is suspended at the correct height, typically in the middle third of the slab, it can effectively resist forces that cause cracking and structural failure.

Concrete mesh support chairs are specifically designed to achieve this precise placement. They ensure proper concrete flow around the reinforcement, preventing issues like honeycombing or voids. By elevating the mesh consistently, they also help prevent corrosion by ensuring adequate concrete cover, protecting the steel from moisture and chemical ingress. This consistent height also facilitates even load distribution across the slab, meaning your concrete will perform as intended for years to come.

Beyond structural benefits, using purpose-built mesh chairs offers significant labor savings. Gone are the days of a “hook man” painstakingly lifting and adjusting the mesh during the pour. With chairs, the mesh is set and secure before the concrete even flows, streamlining the process and reducing on-site manpower. This professional approach drastically reduces the risk of structural failure and ensures that every project, from a simple patio to a complex commercial floor, stands strong.

For more information on the various supports available for your concrete projects, you can explore resources on Supports for Wire Mesh and Rebar – Supplies .

The Problem with Makeshift Supports

Let’s talk about those “alternatives” we mentioned earlier: bricks, scrap wood, rocks, or even chunks of concrete. While they might seem like a quick fix, they are far from ideal.

Imagine a scenario: you’re pouring a new driveway. You’ve laid out your wire mesh, and now you’re using broken bricks to lift it. The issues start immediately. The bricks offer inconsistent support heights, leading to portions of your mesh being too high, too low, or completely resting on the subgrade. This unevenness means some areas of your slab will be significantly weaker than others.

Furthermore, these makeshift supports can absorb moisture, leading to potential spalling (surface flaking) in the concrete above them. If they’re made of organic materials like wood, they can decompose over time, leaving voids within your slab. Metal scraps can introduce rust bleed, staining your finished concrete surface and potentially initiating corrosion of your reinforcement. Perhaps most critically, these items can puncture your vapor barrier, compromising its ability to prevent moisture transfer from the ground, which is vital for the long-term health of your slab. While they might save a few dollars upfront, they compromise the very strength and longevity of your concrete, leading to costly repairs down the line.

The Professional Solution: Engineered Support

Now, let’s contrast that with the professional approach: using engineered concrete mesh support chairs. These chairs are specifically designed to eliminate the problems associated with makeshift supports and lift your concrete project to a higher standard.

Our chairs provide unwavering stability. With features like wide, round bases, they prevent sinking into the subsurface, even on softer grades. This ensures uniform placement of your mesh across the entire slab. When we say uniform, we mean consistent concrete cover, which is critical for protecting the steel reinforcement from corrosion and ensuring the slab’s designed strength.

Another key benefit is the prevention of membrane puncture. Unlike jagged rocks or sharp wood, our chairs are designed with smooth surfaces that won’t damage your vapor barrier. This maintains the integrity of your moisture protection system, a crucial element for any slab on grade.

Finally, and perhaps most appreciated by those on the job site, engineered chairs significantly reduce manpower. As one of our sources highlighted, they can eliminate the need for a “hook man” to constantly adjust the wire mesh during the concrete pour. Once our chairs are snapped onto the mesh and placed, they stay put. This efficiency not only saves labor costs but also speeds up the pouring process, keeping your project on schedule.

For more insights and helpful guides, be sure to check out More info about our resources.

A Guide to Choosing and Using Concrete Mesh Support Chairs

Choosing and using the correct concrete mesh support chairs is fundamental to the success and longevity of any concrete pour. Whether you’re tackling a small home project or a large commercial slab, getting the reinforcement placement right is non-negotiable. Our chairs are versatile and perfect for a wide range of applications where wire mesh reinforcement is used.

Consider these common real-world uses where our mesh chairs excel:

- Patios: Ensuring your outdoor living space has a strong foundation that resists cracking from freeze-thaw cycles or heavy furniture.

- Sidewalks: Providing durable, long-lasting pedestrian paths that can withstand foot traffic and environmental stressors.

- Driveways: Creating robust surfaces that can handle the weight of vehicles without developing premature cracks or potholes.

- Garage Slabs: Building solid foundations for your garage that can support vehicles, heavy equipment, and resist moisture intrusion.

- Basement Floors: Critical for ensuring a dry, stable base for your home’s lowest level, preventing issues like moisture transfer and structural weakness.

- Liftd Decks: For commercial projects, ensuring the structural integrity of upper-level concrete decks.

- Footings: Supporting reinforcing steel in the foundational elements of structures.

These applications all benefit immensely from the precise mesh placement that only dedicated mesh chairs can provide. To dive deeper into optimal reinforcement strategies, take a look at our Rebar Placement Guide.

Choosing the Right Type of Concrete Mesh Support Chairs

The world of concrete mesh support chairs isn’t one-size-fits-all. Different projects and conditions call for different materials and designs. Understanding the types available will help you make the best choice for your specific needs.

We primarily deal with steel mesh chairs, which we believe offer superior performance for many applications. However, it’s worth understanding the broader landscape.

Here’s a quick comparison of common types:

| Feature | Plastic Mesh Chairs | |

|---|---|---|

| Durability | Steel Mesh Chairs | Extremely durable, resilient, and resistant to environmental stressors. |

| Cost | Plastic Mesh Chairs | Generally more cost-effective per unit, making them suitable for large-scale projects with budget constraints. |

| Application | Steel Mesh Chairs | Ideal for heavy-duty applications, commercial projects, and situations where maximum strength and longevity are paramount. Our Hercules 2″ Steel Mesh Chairs, for instance, are designed for 6, 8, and 10 Gauge Steel Wire and are perfect for patios, sidewalks, driveways, and garages. |

| Flexibility/Rebound | Plastic Mesh Chairs | Some plastic chairs are designed with a “deflect and rebound” feature, meaning they can be stepped on during installation and spring back to their original position without permanent damage. This can be a practical benefit during pours. |

| Material Conformance | Steel Mesh Chairs | Our steel chairs are manufactured from wire conforming to high industry standards like ASTM A82/82M, ensuring quality and consistency. |

| Continuous vs. Individual | Both materials come in individual chairs (like our Hercules chairs) and continuous forms (long strips of chairs). Continuous mesh chairs, often made of wire, are excellent for covering large areas quickly, while individual chairs offer flexibility in placement. | |

| Slab on Grade vs. Liftd Decks | Both types can be used for slab on grade. For liftd decks or bridge decks, continuous wire chairs that meet specific CRSI standards are often preferred for their robust support. |

We at Hercules Rebar Chairs focus on providing robust steel mesh chairs. Our Hercules 2″ Steel Mesh Chair, for example, is specifically designed for 6, 8, and 10 Gauge Steel Wire, offering best performance and reliability for your projects.

Sizing and Spacing: The Keys to a Strong Foundation

Getting the right height and consistent spacing for your concrete mesh support chairs is crucial. It’s not just about lifting the mesh; it’s about lifting it to the correct height and ensuring that height is maintained uniformly across the entire slab.

-

Slab Thickness and Chair Height: The height of your mesh chair directly relates to the thickness of your concrete slab. The goal is to place the mesh in the middle to upper-middle third of the slab. For instance, if you’re pouring a 4-inch slab, a 2-inch chair would typically position the mesh perfectly. Some chairs are designed for specific slab thicknesses; for example, certain plastic chairs are ideal for 3-inch to 5-inch slabs with a 1-1/2 inch height. Our Hercules 2″ Steel Mesh Chair has an overall height of 2-3/8 inches, making it suitable for many standard slab applications.

-

Wire Gauge Compatibility: Ensure your chosen chair is compatible with the gauge of your wire mesh. Reinforcement mesh commonly comes in 6, 8, or 10 gauge wire. Our Hercules 2″ Steel Mesh Chair, for example, is designed specifically to support 6, 8, and 10 Gauge Steel Wire, providing a secure fit that won’t dislodge during installation or pouring.

-

Spacing Guidelines: Proper spacing is vital for uniform support. If chairs are too far apart, the mesh can sag between them, defeating the purpose of elevation. For our Hercules 2″ Steel Mesh Chair, we recommend placing a chair every 24 inches in each direction. This creates a grid of support that effectively maintains the mesh’s position. This recommended spacing is a critical factor in ensuring that the mesh remains liftd and functional throughout the concrete pour.

To help you accurately determine the number of chairs needed for your project, we offer a handy tool. You can Use our estimator for your project.

Step-by-Step Installation Guide

Installing concrete mesh support chairs is a straightforward process, but getting it right ensures maximum effectiveness. Here’s our recommended step-by-step guide:

- Prepare Your Area: Ensure your subgrade is properly prepared, compacted, and that any vapor barrier is laid out smoothly.

- Position Your Mesh: Lay out your wire mesh panels over the prepared area. Overlap them according to your project specifications or local building codes.

- Attach the Chairs: This is where our chairs make life easy! Our chairs feature a snap-on mechanism. Simply snap the clips of the chair onto the wire’s crossing from the bottom. Do this at the intersections of your mesh wires. The goal is a firm, secure attachment that won’t easily come loose.

- Mind the Spacing: Following our recommendation, place a chair every 24 inches in each direction. This grid-like pattern ensures consistent elevation and support across the entire mesh.

- Pre-Pour Inspection: Before the concrete truck arrives, do a final walk-through. Check that all chairs are securely attached, the mesh is at the correct height, and there are no loose sections.

- Walk with Confidence: One of the great advantages of our high-quality chairs is their ability to handle foot traffic. You can walk on the mesh between chairs during installation without causing permanent damage. The mesh will temporarily deflect under your weight but spring right back into place once you step off, thanks to the resilient design of the chairs.

- Pour the Concrete: Now you’re ready! With the mesh securely liftd by our chairs, you can pour your concrete with confidence, knowing the reinforcement will stay exactly where it needs to be.

Our chairs are designed to be an integral part of your concrete slab. They get buried in the concrete and are not removed during the pour. They become a permanent fixture, ensuring the long-term strength and durability of your project.

For more details on our specific products and how they integrate into your project, you can View the 2 Inch Steel Mesh Chair.

Key Specifications and Industry Standards

Understanding the specifications and industry standards for concrete mesh support chairs is not just for engineers; it’s essential for any contractor or DIY enthusiast who wants to ensure a quality, code-compliant concrete pour. These details speak to the durability, reliability, and performance of the chairs you choose.

When we talk about specifications, we’re looking at things like the chair’s height, its material composition, its compatibility with different wire gauges, and its load-bearing capacity. These factors directly impact how well the chair performs its critical function of holding reinforcement in place. A chair that’s too weak or made of inferior material simply won’t do the job, leading to compromised structural integrity.

Our commitment to quality means we focus on chairs that meet or exceed these critical standards, ensuring that every project you undertake benefits from a strong, stable foundation. For a deeper dive into our product specifics, you can View our product data sheet.

Key Features to Look for in Concrete Mesh Support Chairs

When purchasing concrete mesh support chairs, certain features stand out as indicators of quality and effectiveness. We’ve designed our chairs with these critical elements in mind to provide you with the best possible support for your concrete reinforcement.

- Wide Base Design: A wide, stable base is paramount. It prevents the chair from sinking into the subgrade, especially on softer or uneven surfaces. This ensures consistent elevation of your mesh, which is fundamental for proper concrete cover and structural performance.

- Stable Support: Beyond the base, the overall design of the chair must offer inherent stability. This means it won’t easily tip or shift when the mesh is placed or during the concrete pour, even under the weight of foot traffic.

- Snap-In Top or Secure Grip: The mechanism that holds the mesh in place is crucial. Our chairs feature a secure clip system that snaps firmly onto the wire intersections. This positive engagement prevents the mesh from dislodging or rotating, maintaining its precise position throughout the entire process. Some continuous mesh chairs also feature snap-in tops that allow panels to be moved without the chairs dislodging.

- Material Quality: For our steel mesh chairs, the quality of the steel wire is non-negotiable. We ensure our materials conform to rigorous industry standards, guaranteeing durability and long-term performance within the concrete. This also means our chairs are robust enough to handle the stresses of a construction site.

These features collectively contribute to a chair’s ability to “get the job done right!” and provide “unrivaled performance,” as we like to say about our products. For a prime example of these features in action, we invite you to See an example of a quality steel mesh chair.

Understanding Compliance: ASTM and CRSI Standards

In concrete construction, adherence to industry standards isn’t optional; it’s a mark of quality, safety, and reliability. When it comes to concrete mesh support chairs, two key standards organizations often come into play in the United States: ASTM International and the Concrete Reinforcing Steel Institute (CRSI).

- ASTM A82/A82M: This standard specification covers cold-drawn steel wire for concrete reinforcement. When our steel mesh chairs are manufactured from wire conforming to ASTM A82/A82M, it means the material has met specific requirements for tensile strength, yield strength, and other mechanical properties. This ensures the wire itself is of a consistent, high quality, contributing to the overall integrity of the support chair and, by extension, your concrete slab.

- CRSI Standards: The Concrete Reinforcing Steel Institute (CRSI) provides comprehensive standards and practices for reinforcing steel and its accessories, including bar supports. CRSI standards address aspects like design, manufacturing, and application of these supports. When a mesh chair meets CRSI standards, it signifies that the product has been evaluated and approved for use in concrete construction according to established industry best practices. This provides an additional layer of quality assurance, ensuring the support chairs perform as expected in critical structural applications.

Adherence to these standards is crucial for code compliance. Many local building codes in the US reference ASTM and CRSI standards, making it imperative that the products you use meet these requirements. This not only ensures the safety and durability of your construction but also helps you pass inspections without a hitch.

Furthermore, for many government or public works projects, there’s often a “Buy America” requirement. This means that products must be manufactured in the United States from substantially US-sourced components. We understand the importance of these domestic requirements and strive to ensure our products meet these criteria where applicable.

By choosing concrete mesh support chairs that conform to ASTM and CRSI standards, you’re investing in quality assurance and peace of mind. You’re ensuring that the foundation of your project is built with reliable components that contribute to its long-term strength and integrity. To learn more about our commitment to these high standards, visit Learn more about our company standards.

Frequently Asked Questions about Concrete Mesh Supports

We often get excellent questions about the practical use of concrete mesh support chairs. Here are some of the most common ones we encounter, along with our expert answers.

Can I walk on the wire mesh after the chairs are installed?

Yes, you absolutely can! This is one of the distinct advantages of using well-designed concrete mesh support chairs. Our chairs are engineered to allow for movement on the mesh during the installation process without causing permanent damage to the mesh’s position.

When you step on the wire mesh, it will naturally deflect or push down slightly. However, thanks to the inherent resilience and design of our chairs, the mesh will spring right back up into place once you step off. This “deflect and rebound” capability is a testament to the robust construction of our chairs and their ability to maintain the mesh’s proper elevation. This feature is incredibly helpful on a busy job site, as it means you don’t have to be overly cautious about every step, making the installation process more efficient and less frustrating. Just ensure proper installation, and you can walk with confidence.

What is the correct spacing for mesh chairs?

The correct spacing for concrete mesh support chairs is crucial for ensuring uniform support and preventing the mesh from sagging between the chairs. While specific project specifications might vary, a general and highly effective guideline for our Hercules 2″ Steel Mesh Chairs is to place them every 24 inches in each direction.

This creates a consistent grid of support across the entire area where the mesh is laid. By maintaining this 24-inch spacing, you guarantee that the wire mesh remains liftd at its intended height, providing optimal tensile strength throughout your concrete slab. Deviating too much from this guideline can lead to inconsistent concrete cover, which can weaken the slab in unsupported areas. Always consult your project’s specific plans, but this 24-inch rule is an excellent starting point for most standard applications.

To help you accurately calculate the number of chairs you’ll need and visualize the optimal spacing for your specific project dimensions, we’ve developed a helpful tool. You can Use our placement estimator.

Do the chairs get removed before pouring the concrete?

No, absolutely not! This is a common misconception, especially for those new to concrete work. Concrete mesh support chairs are specifically designed to be left in place and buried within the concrete.

They are an integral part of the reinforcement system, ensuring that the wire mesh maintains its position not just before the pour, but also during and after the concrete sets. Attempting to remove them would disturb the mesh, defeat its purpose, and potentially compromise the structural integrity of your slab. Think of them as permanent components that work in harmony with the wire mesh to create a stronger, more durable concrete structure. Our chairs are made to be encased, becoming a discreet yet vital part of your finished project.

Conclusion

We’ve explored concrete mesh support chairs, from their fundamental purpose to the intricate details of their selection and installation. It’s clear that these small but mighty components are indispensable for achieving a high-quality, durable concrete slab. By ensuring your wire mesh is perfectly positioned, you’re not just pouring concrete; you’re building a foundation that will stand the test of time.

Choosing engineered supports over makeshift alternatives provides a multitude of benefits: superior structural integrity, consistent concrete cover for corrosion protection, significant labor savings, and peace of mind knowing your project meets industry standards. Whether you’re reinforcing a patio, driveway, garage, or a commercial deck, the precision offered by dedicated mesh chairs is simply best.

For project success and long-term durability, we encourage you to prioritize the proper elevation of your reinforcement. Our Hercules Rebar Chairs, identifiable by their signature red color, are trusted by professionals across the nation to deliver strength and reliability. We’ve sold over 14 million units, saving time and money for countless projects while ensuring code compliance.

Ready to lift your next concrete project with confidence? You can find our high-quality solutions, including our renowned red chairs, through various nationwide retail stores, major online retailers, or directly on Amazon. Take the first step towards a stronger foundation and Buy Rebar Chairs. We’re confident that once you experience the difference our products make, you’ll understand why we’re America’s #1 choice for concrete supports.

For specific details and to get started on your next build, be sure to View the Hercules 2″ Steel Mesh Chair for your next project.