Why 3-Inch Rebar Chairs Are Essential for Concrete Strength

3 inch rebar chairs are plastic or steel supports that lift reinforcing steel exactly three inches off the ground during concrete pours. Here’s what you need to know:

Top 3-Inch Rebar Chair Options:

| Product Type | Material | Best For | Key Benefit |

|---|---|---|---|

| Hercules #912 | Plastic | 6-8″ commercial slabs | Snap-in design, no wire tying |

| Heavy-Duty Steel Chair | Steel | Heavy-duty footings | Maximum stability for heavy loads |

| Standard Plastic Chair | Plastic | General slab on grade | Lightweight and non-corrosive |

If you’re a concrete contractor tired of wrestling with wire ties while your rebar sinks into the mud, you’re not alone. Traditional wire tying methods waste time, cost labor dollars, and often fail to maintain proper concrete cover during the pour. That’s a recipe for structural problems down the road.

A quality 3-inch rebar chair solves these problems by providing stable, consistent support for #4 and #5 rebar in commercial concrete applications. These simple devices snap into place in seconds, hold your rebar grid exactly where it needs to be, and stay buried in the concrete to provide permanent structural support.

The three-inch clearance is specifically designed for concrete slabs ranging from 6 to 8 inches thick. This ensures proper concrete cover over your rebar—critical for preventing corrosion and maintaining the structural integrity your projects demand. According to the research, products like the Hercules #912 are built for this exact purpose, supporting commercial-grade pours while maximizing concrete flow around the chair.

Whether you choose plastic chairs for their lightweight, rust-free performance or steel chairs for maximum load-bearing strength, the right 3-inch rebar chair will save you time and money while delivering code-compliant results.

The Foundation of Strength: What is a Rebar Chair?

When it comes to concrete construction, a strong foundation is everything. And at the heart of that strength lies properly placed reinforcing steel, or rebar. This is where the mighty 3-inch rebar chair steps in, playing a crucial, yet often unsung, role.

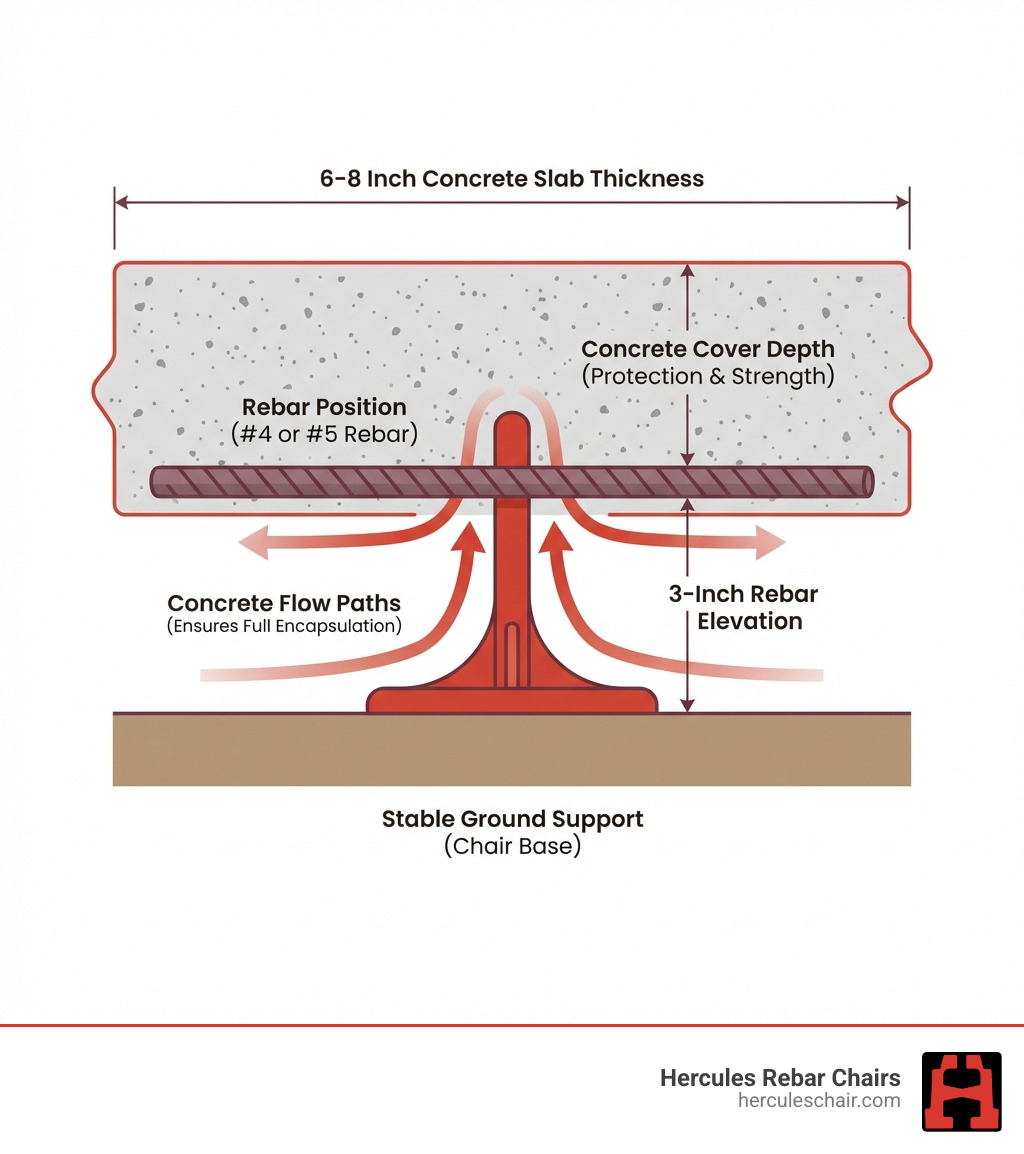

So, what exactly is a 3-inch rebar chair? In simple terms, it’s a specialized support device designed to lift rebar to a precise height within a concrete pour. Its primary function is to create and maintain a consistent 3-inch clearance between the ground (or formwork) and the bottom layer of rebar. This exact elevation ensures that the rebar is fully encapsulated by concrete, a vital process known as achieving proper concrete cover.

Why is this so important? Without adequate concrete cover, rebar is exposed to moisture and oxygen, leading to corrosion. Corroding rebar expands, cracking the surrounding concrete and severely compromising the structural integrity of the entire slab or footing. By holding the rebar firmly in its intended position, a 3-inch rebar chair prevents it from sinking during the concrete pour, protecting against premature corrosion and significantly enhancing the longevity and stability of your concrete structure. It’s not just about support; it’s about safeguarding your investment and ensuring your project stands the test of time.

To learn more about our commitment to quality and innovation in concrete supports, visit More info about our company.

Benefits Over Traditional Methods

For generations, concrete contractors have relied on various methods to prop up rebar, from makeshift stones and bricks to the tedious process of wire tying. While these methods might seem cost-effective initially, they often come with hidden costs in terms of time, labor, and inconsistent results. This is where the modern 3-inch rebar chair truly shines, offering a host of benefits that make traditional approaches feel, well, traditional!

One of the most significant advantages is the immense time savings. Imagine a job site where rebar is quickly and efficiently snapped into place, rather than painstakingly tied with wire. Our 3-inch rebar chairs are designed for just this kind of efficiency. They eliminate the need for wire tying, drastically cutting down on installation time and reducing labor costs. This streamlined process means your crew can move faster, covering more ground and keeping your project on schedule.

Beyond speed, these chairs provide consistent placement that traditional methods often struggle to achieve. When rebar is supported by a sturdy 3-inch rebar chair, it stays exactly where it needs to be—before, during, and after the concrete pour. This consistent elevation is critical for maintaining the specified concrete cover, which in turn ensures the structural integrity and durability of the finished product. The chairs are engineered to be stable and will not collapse under the weight of the rebar or during the dynamic process of a concrete pour. This improved stability translates to higher quality work and fewer headaches down the line. By embracing the efficiency and reliability of 3-inch rebar chairs, we help you improve job site efficiency and ensure your concrete structures are built to last.

Plastic vs. Steel: Choosing the Right Material

When selecting a 3-inch rebar chair for your project, one of the first decisions you’ll face is the material: plastic or steel. Both options offer distinct advantages, and the “right” choice often depends on your specific project requirements, the load-bearing needs, and even the environmental conditions of your job site. We offer both types to cater to the diverse needs of concrete construction professionals across the USA.

Plastic Rebar Chairs

Plastic 3-inch rebar chairs are incredibly popular, and for good reason. They are lightweight, making them easy to transport and handle on the job site. A major benefit is their non-corrosive nature; unlike metal, plastic will not rust or cause unsightly rust bleed on the surface of your finished concrete. This makes them an excellent choice for applications where aesthetics are important or where the concrete will be exposed to moisture. Plastic chairs are also often more cost-effective, offering a great balance of performance and budget-friendliness. They are particularly ideal for slab-on-grade applications and situations where insulation or vapor barriers are present, as they will not puncture these critical layers. While robust, their primary drawback can be a generally lower load capacity compared to their steel counterparts, though many plastic chairs are strong enough to hold up to 600 lbs, accommodating rebar sizes up to 1 inch in diameter.

Steel Rebar Chairs

For projects demanding maximum strength and durability, steel 3-inch rebar chairs are often the preferred option. These heavy-duty supports are designed to withstand significant loads, providing exceptional stability for heavier rebar and larger concrete pours. Our steel chairs are typically made from durable materials like annealed steel, which improves their toughness, ductility, and machinability. This material choice ensures they can handle the rigors of commercial and industrial applications. Steel chairs are excellent for footings and other heavy-duty applications where the sheer weight of the rebar grid and wet concrete requires unwavering support. The main considerations with steel are the potential for rust if not properly coated or if the concrete cover is compromised, and generally a higher cost per unit. However, for projects where uncompromising strength is paramount, steel is often the superior choice.

While we are focusing on 3-inch rebar chairs here, we also offer a range of steel support options, such as our 2 Inch Steel Mesh Chair Product 944, designed for different support needs.

TABLE comparing Plastic vs. Steel Rebar Chairs

| Feature | Plastic Rebar Chairs | Steel Rebar Chairs |

|---|---|---|

| Strength | Good, often up to 600 lbs load capacity | Excellent, maximum durability for heavy loads |

| Cost | Generally more cost-effective | Typically higher cost |

| Rust Resistance | Excellent, non-corrosive, no rust bleed | Potential for rust if exposed, typically annealed steel for durability |

| Weight | Lightweight, easy to handle | Heavier, provides robust stability |

| Best Applications | Slabs-on-grade, insulated panels, vapor barriers, general commercial slabs | Heavy-duty footings, large rebar, high-load applications |

A Guide to Using Your 3-Inch Rebar Chair

Using a 3-inch rebar chair might seem straightforward, and in many ways, it is! However, understanding the best practices for installation and placement can significantly impact the strength and longevity of your concrete structure. We’re here to guide you through maximizing the support these chairs provide and ensuring a successful pour every time.

Recommended Placement and Spacing

Proper placement of your 3-inch rebar chairs is crucial for maintaining the integrity of your rebar grid. For concrete slabs and footings, the general rule of thumb is to place a chair at every rebar crossing. This ensures optimal support across the entire reinforcement network. By placing chairs strategically, you prevent any section of the rebar from sagging or shifting, which could lead to inadequate concrete cover.

Whether you’re working on a sprawling commercial slab or a critical footing, our chairs are designed to adapt to various rebar grid layouts. They provide consistent elevation, keeping the reinforcement precisely 3 inches off the ground. This meticulous placement ensures that your rebar stays in the right place before, during, and after the concrete pour, contributing directly to a structurally sound and code-compliant result.

For more detailed guidance on rebar placement, we encourage you to explore our resources:

Estimating How Many Chairs You Need

One of the most common questions we hear is, “How many 3-inch rebar chairs do I need for my project?” Estimating the correct quantity is essential to avoid costly delays or last-minute shortages on the job site. The amount you’ll need depends primarily on the total project area and the spacing of your rebar grid.

While a precise calculation can be complex, a general guideline is to place a chair at every intersection of your rebar grid. For example, if you have rebar spaced at 2-foot intervals in both directions, you’d need approximately one chair for every 4 square feet. We offer our popular Hercules #912 3-inch rebar chairs in convenient pack sizes, including 50-packs and 100-packs, available at major retailers like Home Depot and online.

To simplify this process, we’ve developed helpful tools:

- Use our Hercules Rebar Chair Estimator for a general estimate.

- For specific calculations related to our #912 model, try the Hercules Rebar Chair Estimator 912. These tools help you confidently determine the quantity needed, ensuring you have enough chairs to get the job done right.

Understanding the Design of a 3-inch rebar chair

The effectiveness of a 3-inch rebar chair isn’t just about its height; it’s also about its thoughtful design, engineered to perform under demanding conditions. Our chairs incorporate several key features that facilitate concrete flow and ensure proper support throughout the pour.

Firstly, many of our chairs feature innovative snap-in clips. This design allows rebar to be quickly and securely fastened into the chair without the need for wire tying. This not only saves time and labor but also ensures a firm grip, preventing the rebar from dislodging or shifting during subsequent construction activities or the concrete pour itself.

Secondly, our chairs are designed with a wide, stable base. This broad footprint distributes the load evenly over the ground or formwork, preventing the chair from sinking into soft subgrades or unstable surfaces. This robust stability is critical to ensure the rebar remains at its intended 3-inch elevation, maintaining optimal concrete cover.

Finally, the open design of our 3-inch rebar chairs is specifically engineered to maximize concrete flow. Unlike solid blocks or other obstructive supports, our chairs allow concrete to pass freely around and through their structure. This minimizes voids and honeycombing beneath the rebar, ensuring a complete and uniform encapsulation of the steel. This attention to detail in design ensures that the concrete fully surrounds the rebar, creating a monolithic and durable reinforced slab.

You can view more product details and design specifics for our Hercules #912 chair at View product details.

Specifications and Applications

Understanding the technical details and potential applications of 3-inch rebar chairs is key to selecting the right product for your specific project. These versatile supports are designed to meet a wide range of construction needs, from standard slabs to more complex structures. We pride ourselves on offering products that combine reliability with performance. You can explore our full range of offerings at Our Products.

Typical Dimensions and Rebar Compatibility

When we talk about a 3-inch rebar chair, the “3-inch” refers to the crucial clearance it provides from the ground to the bottom bar of rebar. This exact measurement is vital for achieving optimal concrete cover. For instance, our Hercules #912 chair provides precisely a 3-inch clearance and has an overall height of approximately 4-3/8 inches, accommodating the thickness of the rebar itself.

These chairs are typically designed to support common rebar sizes, with our Hercules #912 specifically engineered for #4 and #5 rebar. However, many 3-inch rebar chairs are versatile enough to accommodate a wider range of rebar, often supporting diameters up to 1 inch, which includes rebar sizes from #3 to #8. The base diameter of these chairs is also important for stability, with many plastic models featuring a base diameter of around 4-1/8 inches to ensure firm footing.

Common Applications for a 3-inch rebar chair

The versatility of a 3-inch rebar chair makes it indispensable across a broad spectrum of concrete construction projects. While they are a staple for standard concrete slabs, their application extends far beyond. Here are some common uses:

- Commercial Concrete Slabs: They are perfect for commercial concrete applications that require 6-inch to 8-inch concrete slabs, ensuring the rebar is correctly positioned for heavy loads.

- Footings: Essential for elevating rebar grids in excavated trenches for concrete footings, preventing the rebar from settling into the soil.

- Vertical Walls: Yes, our chairs can even be used in vertical concrete walls, holding rebar in place as concrete is poured.

- Insulated Sandwich Panels: Certain plastic chairs are ideal for insulated sandwich panel construction, as their design prevents puncturing of insulation or vapor barriers.

- Slab-on-Grade Applications: They provide reliable support for rebar in slab-on-grade constructions, crucial for maintaining structural integrity directly on the ground.

- Poorly Compacted or Loose Soil Conditions: The wide base of many chairs offers improved stability in challenging soil conditions.

- Supporting Mesh or Rebar in Concrete Pours: Whether it’s a grid of rebar or a mesh, these chairs provide the necessary elevation and support.

These applications highlight how a 3-inch rebar chair is not just a single-purpose tool but a fundamental component for ensuring robust, long-lasting concrete structures in various environments across the USA.

Frequently Asked Questions

We understand that even experienced contractors can have questions about optimizing their concrete pours. Here, we address some of the most common queries we receive about 3-inch rebar chairs, offering expert answers to build your confidence and streamline your projects.

Do rebar chairs stay in the concrete?

Absolutely, yes! This is one of the most frequently asked questions, and the answer is a resounding yes. 3-inch rebar chairs are explicitly designed to be left inside the concrete pour. They become an integral, permanent part of the finished concrete structure. Their purpose isn’t just to temporarily hold the rebar; it’s to provide continuous support and maintain the rebar’s position indefinitely. This ensures that the concrete cover remains consistent, protecting the rebar from corrosion and preserving the structural integrity for the entire lifespan of the concrete element. So, once installed and the concrete is poured, rest assured, your rebar chairs are doing their job for good!

Are rebar chairs necessary for reinforced concrete?

We firmly believe they are necessary, and industry standards agree. 3-inch rebar chairs are not just a convenience; they are critical for the proper construction of reinforced concrete elements. Without them, the rebar can easily sink to the bottom of the formwork during the concrete pour, or shift out of position. This results in insufficient concrete cover, leaving the rebar vulnerable to moisture and corrosion, which can lead to premature failure of the concrete structure.

By ensuring the rebar is held precisely at the specified 3-inch elevation, these chairs guarantee proper concrete cover. This adherence to proper rebar placement is crucial for the structural integrity of the concrete and is often a requirement for meeting building codes and engineering specifications. Using 3-inch rebar chairs is a non-negotiable best practice for any reinforced concrete project that aims for durability and safety. Many of our plastic chairs, for example, are designed to meet current CRSI (Concrete Reinforcing Steel Institute) requirements, ensuring compliance and peace of mind.

Can chairs be used for any rebar spacing?

Yes, our 3-inch rebar chairs are designed with versatility in mind and can be effectively used for virtually any rebar spacing configuration. The key is to place them strategically at the intersections of your rebar grid. Whether your rebar is spaced closely or more widely, you simply position a chair wherever the horizontal and vertical bars cross. This method ensures that every critical point of the reinforcement network receives adequate support and elevation. By placing a chair at every crossing, you provide consistent support across the entire rebar matrix, regardless of the specific spacing, making them highly adaptable to diverse project designs and requirements.

Conclusion

We’ve journeyed through the essential world of the 3-inch rebar chair, uncovering its fundamental role in concrete construction. We’ve seen how these seemingly simple devices are pivotal for creating strong, durable, and code-compliant concrete structures. From their primary function of elevating rebar to ensure proper concrete cover, to the significant time and labor savings they offer compared to outdated methods, the benefits are clear.

Whether you opt for the lightweight, non-corrosive advantages of plastic chairs or the maximum strength and durability of steel for heavy-duty applications, the right 3-inch rebar chair is an investment in the longevity and safety of your project. We’ve explored how their smart design facilitates optimal concrete flow, how to strategically place them, and how to estimate your project’s needs.

At Hercules Rebar Chairs, we are proud to be America’s #1 choice, with over 14 million units sold across the nation. Our signature red chairs are synonymous with quality, consistency, and innovation. We are dedicated to providing products that not only save you time and money but also ensure your concrete projects meet the highest standards of structural integrity. When you choose our 3-inch rebar chairs, you’re choosing a solution that helps you get the job done right.

Ready to secure your next concrete project with the best in the business?

You can easily find our Hercules 3-inch rebar chairs and accessories through our nationwide retail stores, major online retailers, or directly on Amazon. Look for our products at Home Depot for convenient access to our 50-packs and 100-packs.