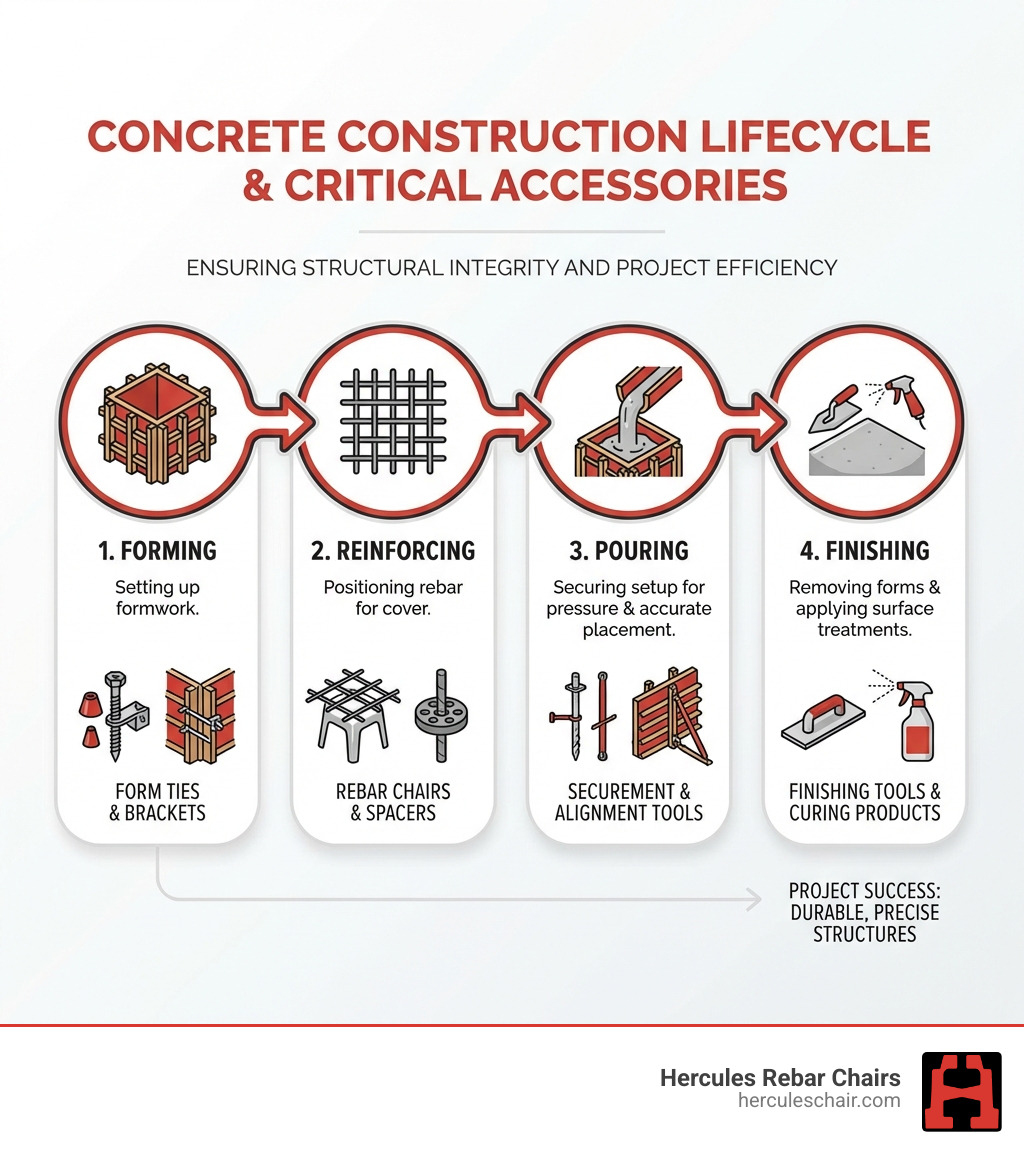

Why Concrete Construction Accessories Are the Unsung Heroes of Every Pour

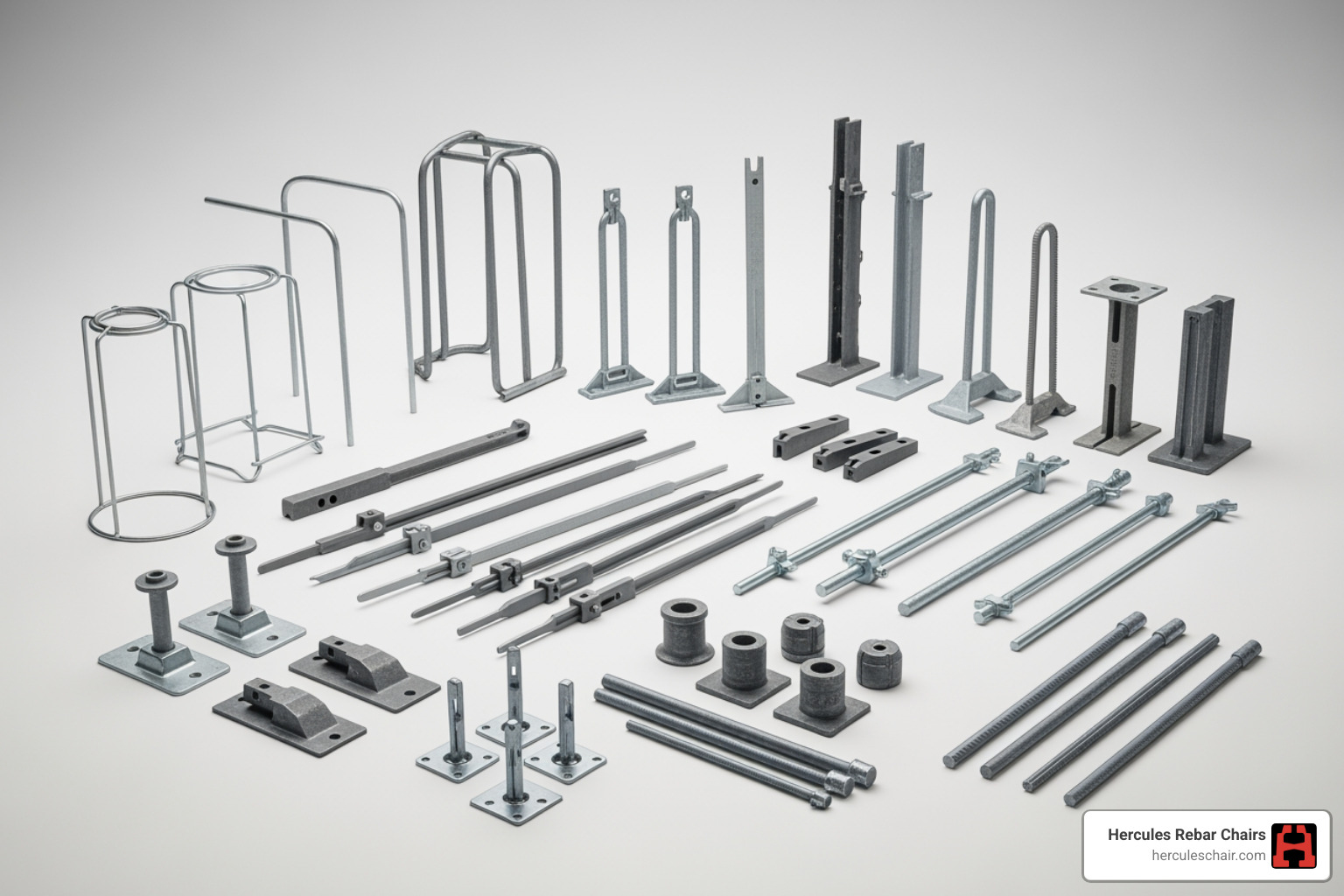

Concrete construction accessories are the specialized tools, supports, and components that ensure reinforced concrete structures are built correctly, safely, and efficiently. They include rebar chairs, form ties, lifting inserts, spacers, and finishing tools that keep steel reinforcement properly positioned and concrete forms secure during the pour.

Key Categories of Concrete Construction Accessories:

- Reinforcement Supports – Rebar chairs, bolsters, and spacers that maintain proper concrete cover

- Formwork Accessories – Ties, brackets, and wedges that secure concrete forms

- Lifting & Handling Devices – Inserts and anchors for tilt-up and precast applications

- Finishing & Curing Products – Release agents, curing blankets, and surface treatment tools

- Specialized Components – Bridge deck hangers, dowel systems, and connection hardware

You may have seen it happen on a job site. The concrete truck arrives, the crew is ready, but the rebar is not sitting where it should be. Maybe it is sagging or the chairs shifted during prep work. Either way, you are about to pour an expensive structural element with compromised cover.

This is where the right accessories make all the difference. High-quality accessories are recognized for their exceptional integrity across every sector of concrete construction. That reputation is not built on fancy marketing; it is built on preventing the kinds of failures that cost contractors time and money.

The concrete itself might be the star of the show, but accessories are what hold everything together. From the rebar chairs that keep steel reinforcement at the right height to the form ties that prevent blowouts under pressure, these components often determine whether your pour becomes a structural success or an expensive do-over.

Whether you are working on a simple slab or a complex tilt-up project, understanding which accessories to use and why can help control labor costs, speed up your timeline, and support code-compliant concrete on every job.

If you want a broader overview of reinforced concrete itself, resources like this reinforced concrete guide provide additional background on how steel and concrete work together.

The Backbone of the Build: Primary Categories of Concrete Accessories

When we talk about concrete construction accessories, we are covering a wide array of products designed to support every stage of a concrete project. Think of them as the essential supporting cast that allows the concrete itself to perform its starring role. Without these unsung heroes, even the best concrete mix would struggle to achieve its full potential. Our products, like our robust rebar chairs, are designed to be part of this critical support system.

The primary categories help organize these diverse tools:

- Formwork Accessories: These components hold the concrete in its desired shape until it sets. They include everything from the ties that help prevent forms from bulging to the brackets that support their structure.

- Reinforcement Supports: Crucial for maintaining the correct position of steel reinforcement (rebar) within the concrete, ensuring proper cover and structural integrity. This is where our strong rebar chairs truly shine, providing the elevation and stability needed for code compliance. You can see our range of products at Hercules Rebar Chairs – Our Products.

- Finishing & Curing Products: Once the concrete is placed, these accessories help achieve the desired surface finish and support proper curing, which is vital for strength and durability. This category can include items like release agents, curing blankets, and specialized tools for texturing or sealing.

- Lifting & Handling Devices: Especially important for precast and tilt-up concrete construction, these accessories are embedded into the concrete to facilitate safe and efficient lifting, moving, and positioning of large panels or elements.

- Specialized Components: This broad category includes accessories for specific applications, such as bridge deck hangers, dowel bar systems for load transfer, or specialized anchors for various structural connections.

These categories represent foundational elements that contribute to a successful concrete pour, supporting structures that are both durable and efficient to build.

Understanding Formwork Accessories

Formwork accessories are the champions of dimensional accuracy. They are responsible for creating the mold that shapes the concrete, helping walls stay plumb, slabs stay level, and columns form correctly. Without reliable formwork accessories, the pressure exerted by wet concrete can lead to blowouts, misalignments, or bulges.

Key types of formwork accessories include:

- Form Ties: These hold opposite sides of a formwork system together, limiting spreading under the lateral pressure of fresh concrete. Options like snap-tie wedges and cone ties are available for different forming systems.

- Brackets: Used to support formwork components, create corners, or attach bracing.

- Chamfers: Small strips, often made of plastic or wood, inserted into the formwork to create beveled or rounded edges on the finished concrete.

- Coil Products: Often used with form ties and other hardware, these threaded components allow for assembly and disassembly of formwork systems, providing versatility and strength.

The Role of Reinforcement Supports

If rebar is the skeleton of a concrete structure, then reinforcement supports are what hold that skeleton in place. Their primary function is to help ensure that steel reinforcement maintains its position and proper concrete cover before and during the concrete pour.

We, at Hercules Rebar Chairs, focus on this field. Our robust rebar chairs and concrete supports are designed to perform this vital role. Without adequate support, rebar can sag, shift, or get pushed down during the pour. This can lead to insufficient concrete cover, exposing the steel to moisture and air over time.

Common types of reinforcement supports include:

- Rebar Chairs: These individual supports lift the rebar off the subgrade or formwork. Our red Hercules rebar chairs are easily identifiable on job sites across the USA, helping keep the rebar at the specified height.

- Bolsters: Longer, continuous supports used to hold multiple parallel bars at a consistent height over a larger area.

- Spacers: A general term for various devices, often made of plastic or concrete, used to maintain the distance between layers of rebar or between rebar and the formwork.

We offer specialized products like our 2-Bar Footer Stand which is designed for supporting two bars in footers, helping provide stability and consistent placement.

How the Right Accessories Lift Your Project’s Quality, Safety, and Efficiency

The careful selection and use of concrete construction accessories is not just about compliance; it directly affects the outcome of your projects. These seemingly small components collectively impact everything from structural integrity to the budget’s bottom line. Quality products are engineered for performance, strength, and safety, and that is the standard we aim for with every accessory we use.

Achieving Structural Integrity and a Flawless Finish

The core purpose of reinforced concrete is to create structures that are strong and long-lasting. Accessories are critical to achieving this.

- Proper Rebar Cover: Rebar supports like our chairs help ensure that steel reinforcement is encapsulated by the correct amount of concrete. This supports protection of the steel over the life of the structure.

- Preventing Voids: Accessories help maintain the integrity of the formwork and the placement of reinforcement, reducing the likelihood of voids or honeycombing in the concrete.

- Dimensional Accuracy: Formwork accessories help the concrete element match the dimensions specified in the design.

- Architectural Finishes: Accessories like chamfers or formliners help achieve specific aesthetic finishes.

Enhancing Safety on the Job Site

Safety is a priority on any construction site, and concrete construction accessories play a role in mitigating risks.

- Secure Formwork: Properly installed form ties, clamps, and bracing help reduce the risk of sudden formwork failures.

- Stable Rebar Cages: Rebar supports help keep assembled rebar cages stable during the pour.

- Safe Lifting Points: For precast and tilt-up applications, specialized lifting devices are embedded in the concrete. These should be engineered for performance and used according to the manufacturer’s guidance.

- OSHA Guidelines: Many accessories and their installation methods are subject to OSHA guidelines and industry safety standards, reinforcing the need for quality products and proper training.

For more on general job site safety principles, you can also review the OSHA construction overview.

Impact on Project Timelines and Costs

Time is money in construction, and the right concrete construction accessories can streamline operations and support cost control.

- Faster Setup: Pre-engineered accessories, such as our rebar chairs, are designed for quick and straightforward installation, reducing the time spent on formwork and reinforcement setup.

- Reduced Labor: Efficient accessories often require less labor to install or adjust.

- Preventing Costly Delays: By supporting proper rebar placement and secure formwork, accessories help prevent errors that could lead to rework or delays. Our Hercules Rebar Chair Estimator can help with planning, supporting material takeoffs and scheduling.

By investing in high-quality concrete construction accessories, you are investing in the quality, safety, and efficiency of the entire project. Our Rebar Placement Guide offers further insights into optimizing reinforcement setup.

A Closer Look at Essential Concrete Construction Accessories and Their Functions

Let’s look at some of the common and critical concrete construction accessories used for various applications. From foundational rebar support to the specialized needs of modern construction techniques, each accessory serves a specific purpose.

The Critical Role of Rebar Supports in Concrete Construction Accessories

The performance of any reinforced concrete structure depends on correct placement of its steel reinforcement. Rebar supports are the components that make this possible.

- Function: Rebar supports, such as our Hercules rebar chairs, help lift and maintain the steel reinforcement bars (rebar) at a specific height within the concrete formwork.

- Maintaining Concrete Cover: The goal is to achieve the correct concrete cover, the distance between the surface of the rebar and the exterior surface of the concrete. This cover is important for protecting the steel and providing bond strength.

- Positioning Steel Reinforcement: Our rebar chairs help prevent the rebar from settling to the bottom of the form or shifting during the concrete pour.

We offer a variety of rebar supports for different needs. For example, our 3-Bar Footer Stand is designed to support multiple rebar in footer applications, providing stability and consistent elevation. For slab-on-grade or mesh applications, our 2 Inch Steel Mesh Chair offers support. For guidance on layout, see our Footer Stand Placement Guide.

Securing the Mold: Essential Formwork Accessories

Formwork is the temporary mold into which fresh concrete is poured, and formwork accessories are the components that hold this mold together until the concrete cures.

- Function: Formwork accessories help manage the hydrostatic pressure exerted by wet concrete.

- Prevents Blowouts: A major function is to help reduce the risk of blowouts, where the formwork fails under pressure.

- Ensures Dimensional Accuracy: By helping keep the formwork rigid, these accessories support the finished concrete element having the intended dimensions and alignment.

Common formwork accessories include:

- Ties: These connect opposing form panels.

- Wedges: Often used with snap ties to tighten the formwork system.

- Clamps: Used to secure various formwork components, such as walers and strongbacks.

- Brackets: Provide support for various formwork elements.

Specialized Concrete Construction Accessories for Modern Applications

As concrete construction evolves, so do the accessories that support it. Modern techniques like tilt-up and precast construction, along with infrastructure projects like bridge decks and paving, rely on specialized accessories.

- Tilt-Up Inserts: Embedded into concrete panels during casting, providing attachment points for lifting hardware, bracing, and connections to other structural elements.

- Precast Lifting Hardware: Precast concrete elements are manufactured off-site and then transported and lifted into place. Specialized anchors and lifting systems are embedded to support handling.

- Bridge Deck Hangers: Used to support formwork for bridge decks from the structural steel girders below.

- Dowel Bars: Used to help transfer loads across concrete joints (for example, in pavements or slabs) while allowing horizontal movement due to thermal effects.

- Splicers: For situations where rebar needs to be extended or connected, mechanical splicers offer an alternative to lap splicing. Our Splicer provides a solution for rebar connections.

Navigating the Market: Innovations, Standards, and Support

The world of concrete construction accessories is dynamic, with new materials, technologies, and best practices emerging regularly. Staying informed about these developments, understanding the importance of domestic manufacturing, and using technical support are all helpful for successful project execution.

Innovations and Trends in Concrete Accessories

Innovation drives progress in construction, making processes safer, more efficient, and often more sustainable. Some current developments in concrete construction accessories include:

- Composite Materials: There is increased use of composite materials for items like rebar supports. These materials can offer corrosion resistance and lighter weight compared to traditional steel.

- Integrated Technology: Technology is increasingly being used alongside construction accessories. Some companies use software to help with layout, while others track components with identification systems.

- Sustainability: There is growing emphasis on environmentally conscious practices, including using recycled materials in accessory manufacturing and designing products that minimize waste.

- Advanced Anchoring Solutions: The market continues to develop anchor solutions, including adhesive and mechanical anchors, which are important for fastening to concrete and masonry.

These innovations help the industry build more efficiently and with greater consideration for long-term performance.

Choosing Your Supplies: Domestic Quality and Reliability

When selecting concrete construction accessories, the origin of the product can be an important factor for many contractors and project managers in the USA.

- Made in USA: Opting for accessories made in the USA, like our Hercules rebar chairs, supports local manufacturing.

- Quality Control: Domestic manufacturing often allows for close quality control and oversight.

- Supply Chain Reliability: Sourcing domestically can support more predictable lead times and reduce some risks associated with longer shipping routes.

- Cost Considerations: While some imported goods may have lower initial prices, factors like shipping costs and consistency should be considered when comparing long-term value.

For those interested in partnering with a U.S. manufacturer, you can Become a Hercules Dealer and join our network.

The Importance of Technical Support and Safety Standards

Even the best concrete construction accessories are only as effective as their correct application. Technical support and adherence to safety standards play a large role here.

- Engineering Services: Many manufacturers offer engineering assistance, such as helping with layout for lifting points or reviewing accessory selection.

- Load Calculations: Technical support may include help with load calculations for anchors, ties, and lifting devices. Guides like this technical anchor selection reference can be helpful when used alongside project specifications.

- ACI Recommendations: Adherence to industry standards, such as those published by the American Concrete Institute (ACI), provides guidelines for material properties, design, and construction practices.

- Safety Standards: Using accessories safely includes following manufacturers’ installation instructions and general job site safety protocols.

For additional guidance and information on best practices, explore our Resources section, which is designed to help you make informed decisions.

Frequently Asked Questions about Concrete Accessories

We often hear common questions about concrete construction accessories from builders and contractors. Here are some of the frequent inquiries and our answers.

How do I choose the right rebar support for my project?

Choosing the correct rebar support is important for the performance of your concrete. Consider the following:

- Slab Thickness: The rebar chair must lift the rebar to help achieve the specified concrete cover.

- Rebar Size: The diameter of the rebar influences the type and strength of the support needed.

- Load Requirements: Consider the weight of the rebar mat itself, as well as any foot traffic or light equipment that might be on the rebar cage before the pour.

- Base Material (Soil vs. Vapor Barrier): If pouring directly on soil, a wider base on the chair can help reduce sinking. If a vapor barrier is present, chairs should be compatible with it.

For more general background on how rebar works within concrete, you can reference this overview of rebar in reinforced concrete.

What is the purpose of a form tie?

The purpose of a form tie is to hold concrete formwork together against the lateral pressure of fresh concrete, helping ensure the wall or structure is the intended thickness. As wet concrete is poured, it exerts hydrostatic pressure on the formwork. Form ties pass through the formwork and are secured on the outside, creating a system that helps maintain the form’s dimensions.

Can concrete accessories be reused?

The reusability of concrete construction accessories depends on the specific accessory type and its design.

- Reusable: Many formwork components, such as steel form panels, strongbacks, walers, and certain types of clamps and brackets, are designed for multiple uses, provided they are cleaned, maintained, and inspected for damage.

- Single-Use: Items like most form ties (for example, snap ties), embedded lifting inserts, and many types of rebar chairs are typically designed for single use. Once concrete sets around them, they become part of the structure or are no longer suitable for reuse.

- Limited Reuse: Some accessories might have limited reuse potential, often requiring careful extraction and inspection before they are used again.

Always consult the manufacturer’s guidelines and applicable safety standards to determine if an accessory can be reused safely and effectively.

Conclusion: Building with Confidence from the Ground Up

In concrete construction, it is easy to focus on mix design or the volume of concrete poured. However, as we have seen, concrete construction accessories are far more than minor components; they underpin the quality, safety, and efficiency of every project. From supporting precise rebar placement to helping maintain the integrity of formwork, these accessories work quietly in the background on every pour.

The right accessories help reduce rework, support job site safety, and contribute to the long-term performance of the finished structure. Whether you are building a residential foundation, a commercial project, or an infrastructure element, understanding and selecting appropriate accessories is a key step toward success.

At Hercules Rebar Chairs, we manufacture strong rebar chairs and concrete supports that are designed with these demands in mind. As “America’s #1” choice, with over 14 million units sold, our products are engineered to help save time and money, support code compliance, and are easily identifiable by their distinctive red color.

By prioritizing quality accessories and staying informed about industry innovations and best practices, you can continue to build structures that stand the test of time.

Explore our durable 3-Bar Footer Stand for your next project