Why Proper Reinforcement Support is Critical for Concrete Slabs

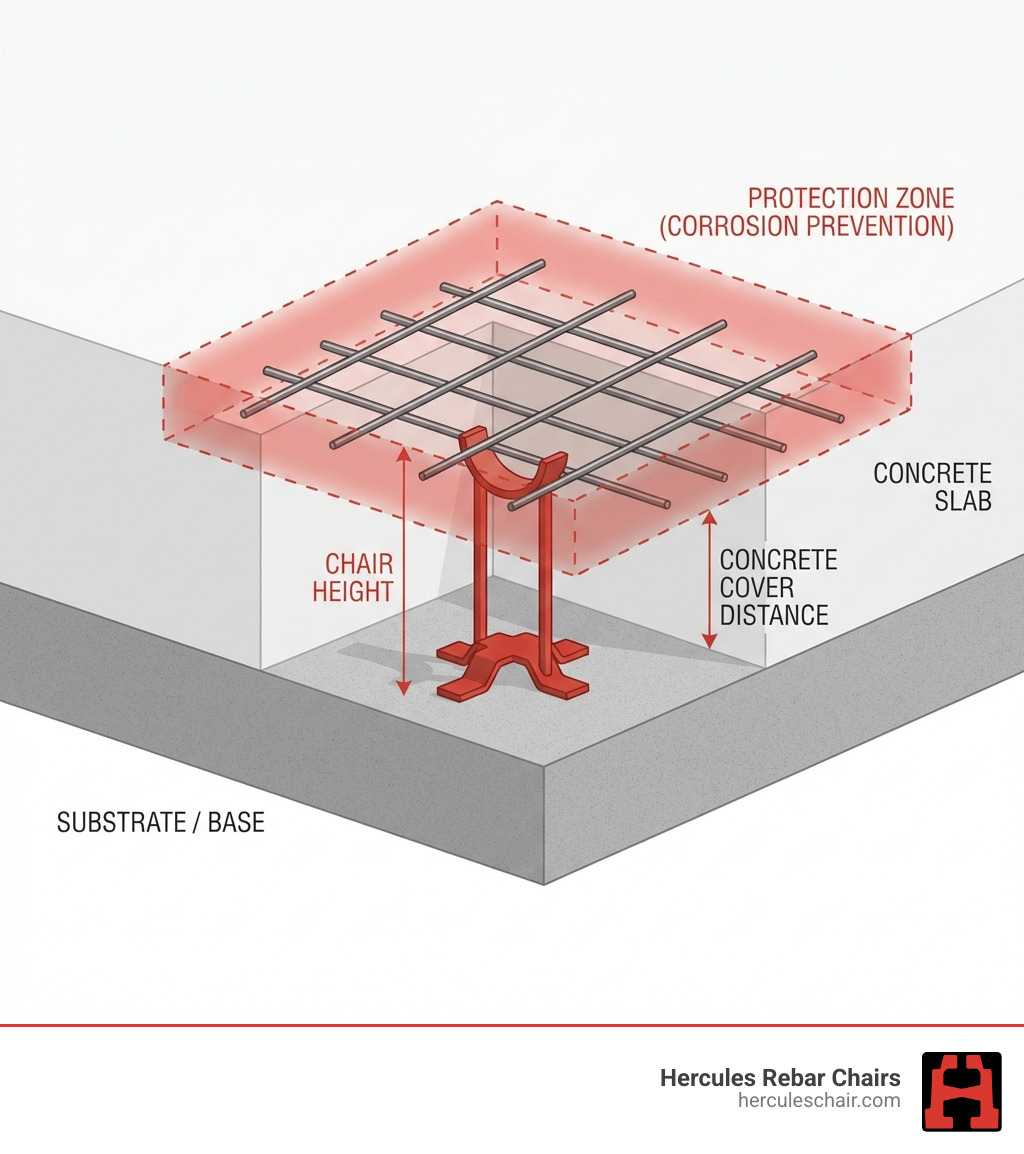

Chair in slab reinforcement refers to the plastic or metal supports placed beneath reinforcing steel (rebar or mesh) to maintain proper elevation and spacing during concrete placement. These supports ensure the reinforcement stays at the correct height within the slab, providing essential concrete cover that protects the steel from corrosion and maintains structural integrity.

Quick Answer: What Rebar Chairs Do

- Maintain concrete cover – Keep reinforcement at the specified distance from the slab bottom

- Support heavy loads – Hold rebar in position during concrete pouring and foot traffic

- Prevent corrosion – Ensure adequate concrete protection around steel reinforcement

- Meet building codes – Comply with standards like AS/NZS 2425:2015 and ACI 318

In reinforced concrete construction, proper positioning of reinforcement is crucial for structural integrity. As one industry guide notes, “Bar chairs, the unsung heroes of concrete work, ensure correct placement and cover of reinforcing steel.”

Yet many contractors still struggle with chairs that crush under pressure, corrode and stain concrete, or fail to meet code requirements. The wrong chair—or incorrect placement—can compromise an entire pour, leading to costly repairs or structural failures down the line.

This guide explains everything you need to know about rebar chairs: the different types available, how to calculate spacing requirements, what building codes require, and how to avoid common placement mistakes. Whether you’re working on a residential slab-on-ground or a commercial liftd deck, understanding chair selection and placement will save you time, money, and headaches on every concrete project.

Understanding Rebar Chairs: Function and Types

When we talk about the unsung heroes of concrete construction, the chair in slab reinforcement definitely earns a spot at the top. These small but mighty components play a colossal role in the long-term strength and durability of our concrete structures. Their primary function is straightforward: to lift and secure the reinforcing steel at the precise height required by engineering designs. This ensures that the rebar is correctly encased within the concrete, creating a robust, structurally sound slab. Without them, our rebar would likely sink to the bottom during the concrete pour, rendering it ineffective.

The Critical Role of Concrete Cover

The significance of maintaining adequate concrete cover cannot be overstated. Concrete cover is the distance between the surface of the reinforcing steel and the exterior surface of the concrete. Why is this so crucial?

Firstly, it protects the steel from environmental elements like moisture and chemicals, which can cause corrosion. Corroding rebar expands, leading to cracking and spalling of the concrete, severely compromising the slab’s integrity and lifespan. We want our structures to last, and proper cover is key to that longevity.

Secondly, concrete cover provides fire resistance. A sufficient layer of concrete insulates the steel, preventing it from reaching critical temperatures that would cause it to lose strength during a fire.

Thirdly, it allows the concrete and steel to work together as a composite material, maximizing the strength and performance of the reinforced concrete. The bond between concrete and steel is essential for the transfer of stresses, and proper cover facilitates this bond.

Tolerances for concrete cover are typically stringent. For instance, in many applications, the position tolerance for surfaces controlled by cover can be as tight as -5mm to +10mm, while for slabs-on-ground, it might be -10mm to +20mm. These tolerances highlight the precision required in placing reinforcement. Our rebar chairs are designed to help you meet these exacting standards, ensuring that every slab we pour is built to last and complies with relevant building codes like ACI 318, which is the cornerstone for concrete design in the US.

Common Types of Rebar Chairs and Their Applications

The world of rebar chairs is more diverse than you might imagine, with each type designed for specific applications and conditions. Here at Hercules Rebar Chairs, we pride ourselves on offering a range of robust solutions to meet every project’s needs.

Here are some of the most common types you’ll encounter:

- Plastic Chairs: These are increasingly popular due to their non-corrosive properties and ease of use. They come in various heights and designs, making them versatile for many slab applications. Many of our Hercules chairs fall into this category.

- Metal Chairs: Traditionally used, metal chairs offer high strength and can support heavier loads. However, care must be taken to ensure they don’t corrode and stain the concrete, or compromise the concrete cover if not properly protected.

- Combination Slab-On-Ground Chairs: These are specially designed for ground floor slabs, often featuring dual heights and a wide base. Our combination chairs are designed to support steel without puncturing vapor barriers, making them ideal for slab-on-grade applications where moisture protection is critical.

- Individual High Chairs (H-Chairs): Known for their robust design and high load capacity, Individual High Chairs (or H-Chairs) are excellent for supporting heavy reinforcement in foundations, liftd slabs, and other demanding applications. Our H Chair Series, for example, offers over 20 height options and can accept #3 – #8 rebar with an impressive 1000lb weight capacity, making them incredibly versatile. You can explore our full range of robust rebar supports at Our Products.

- Castle Chairs: A specific type of plastic chair, often conical in design, that can offer multiple heights with a simple turn, reducing inventory needs.

- Footer Stands: Essential for foundational elements, footer stands provide stable support for rebar in footings and trenches. We offer options like our 3 Bar Footer Stand and 2 Bar Footer Stand to ensure your foundations are as strong as possible.

Advantages of Modern Plastic Rebar Chairs

We’re big believers in the power of innovation, and modern plastic rebar chairs, particularly those made from recycled polypropylene, represent a significant leap forward in concrete construction. Our Hercules chairs embody these advantages:

- Non-Corrosive Material: Unlike metal chairs that can rust and stain concrete or even lead to structural issues over time, our plastic chairs are inherently non-corrosive. This means lasting protection for your rebar and a pristine concrete finish.

- Superior Strength: Don’t let the word “plastic” fool you. Our chairs are engineered for superior strength. For instance, our H Chair Series is tested to hold up to 1000lb, demonstrating that plastic can indeed be incredibly strong when designed correctly.

- Lightweight and Stackable: This translates directly into easier handling on the job site, reducing fatigue and improving efficiency. Their stackable design also means less storage space is required.

- Wide Base for Stability: Many of our plastic chairs feature a wide, integrated base that provides excellent stability, especially on softer subgrades or when used with vapor barriers. This design prevents the chairs from sinking and helps protect delicate membranes. For applications involving vapor barriers, our specialized Vapor Barrier Mat ensures optimal performance.

- Code Compliance: Our Slab-On-Grade Chairs, for example, meet the requirements to qualify as a CRSI Class 1 Bar Support and meet CRSI requirements per table 3-4, giving you peace of mind that your project adheres to industry standards.

Correct Spacing and Placement of a Chair in Slab Reinforcement

Ensuring the correct spacing and placement of a chair in slab reinforcement is as critical as selecting the right chair itself. Think of it as building a strong, invisible scaffolding for your rebar. A well-placed grid of chairs guarantees that the reinforcement remains perfectly positioned throughout the entire concreting process, from the initial pour to the final set. This meticulous attention to detail prevents issues like rebar sag or displacement, which can severely weaken the finished slab.

Key Factors Influencing Chair in Slab Reinforcement Spacing

Determining the ideal spacing for your rebar chairs isn’t a one-size-fits-all scenario. Several key factors come into play, and understanding them is crucial for a successful pour:

- Reinforcement Size and Weight: This is perhaps the most significant factor. Heavier and larger diameter rebar (like #8 bars) naturally exert more weight, requiring closer chair spacing to prevent sagging. Conversely, lighter mesh or smaller diameter rebar can typically tolerate wider spacing. Our H Chair Series, for example, is designed to support #3 – #8 rebar, but the spacing will vary depending on the specific bar size and overall weight.

- Slab Thickness: Thicker slabs often mean more concrete weight and potentially more layers of reinforcement, which can influence chair height and spacing requirements.

- Application Type: Is it a residential basement slab, a heavy-duty industrial floor, or a suspended deck? Each application will have different structural demands and, consequently, different spacing guidelines. For instance, a residential pavement might have different requirements than a building foundation.

- Chair Design and Strength: The specific design and strength rating of the chair itself will dictate how many are needed and how they should be spaced. A chair with a higher load capacity might allow for slightly wider spacing compared to a less robust design. Always choose chairs with adequate strength for your application.

- Engineering Drawings and Project Specifications: Above all, always defer to the project’s engineering drawings and specifications. These documents provide the definitive requirements for rebar size, spacing, concrete cover, and chair placement, custom to the specific structural demands of your project. They are your blueprint for success. To help you estimate your needs, our Hercules Rebar Chair Estimator can be a valuable tool.

Spacing Guidelines and Rules of Thumb

While project specifications are paramount, we can offer some general guidelines and rules of thumb for spacing your chair in slab reinforcement:

- General Rule: A simple calculation method often used is to aim for an average of 1 chair per square meter (or roughly 10 chairs per 100 sq ft). This provides a good starting point for many applications.

- Maximum Spacing: For many building constructions in the US, maximum chair spacing can range, but often falls within 2 to 3 feet (approximately 600mm to 900mm). For lighter residential pavements, specific codes might dictate closer spacing. Always consult your local building codes and project specifications for exact maximums.

- Heavier Reinforcement: The heavier your rebar and the more layers you have, the closer your chairs will need to be. This prevents any unwanted sag or movement during the concrete pour.

- Lateral Offset: A crucial best practice is to avoid long, continuous linear runs of supports. Instead, each individual length of support should be laterally offset from its adjacent support by at least 8 inches (approximately 200mm). This simple technique helps prevent potential linear cracking in the concrete that could otherwise occur along a continuous line of weakness.

- Edge Support: Don’t forget the edges! Chairs must be placed sufficiently close to formwork edges to maintain the required concrete cover from all surfaces. This ensures consistent protection for the rebar around the entire perimeter of the slab.

Common Mistakes When Using a Chair in Slab Reinforcement

Even experienced professionals can sometimes fall prey to common mistakes when it comes to rebar chair placement. Avoiding these pitfalls will save you time, money, and prevent structural headaches down the road:

- Exceeding Maximum Spacing: This is arguably the most common error. When chairs are too far apart, the rebar can sag under its own weight, or under the weight of workers and wet concrete. This reduces the concrete cover, exposing the rebar to corrosion and weakening the slab.

- Insufficient Edge Support: Neglecting to place chairs close enough to the formwork edges can lead to inadequate concrete cover at the slab perimeter, creating vulnerable points for corrosion.

- Using Non-Compliant Products: Always ensure the chairs you use comply with industry standards (like CRSI Class 1 in the US) and are suitable for the load. Using weak or inappropriate chairs can lead to collapse during the pour. Our Hercules chairs are designed to meet these rigorous standards, giving you confidence in your build.

- Incorrect Height Selection: Choosing chairs that are too tall or too short will result in incorrect concrete cover, defeating the entire purpose of using chairs. Always double-check your slab thickness and cover requirements.

- Linear Arrangement of Chairs: As we mentioned, placing chairs in a perfectly straight line can create a continuous plane of weakness in the concrete, potentially leading to linear cracking. Always offset adjacent chairs.

- Inadequate Quantity: Underestimating the number of chairs needed for a project is a recipe for disaster. It can lead to the issues mentioned above, such as sagging reinforcement and compromised structural integrity. When in doubt, consult your engineering drawings or use our Hercules Rebar Chair Estimator. For specific placement tips, check out our Footer Stand Placement Guide.

Technical Specifications, Standards, and Design Considerations

Beyond the practical aspects of placement, understanding the technical specifications and design considerations for a chair in slab reinforcement is essential for engineers and project managers. This involves delving into load calculations, material properties, and adherence to established industry standards like those from the American Concrete Institute (ACI) and the Concrete Reinforcing Steel Institute (CRSI).

Understanding Load and Design Calculations

Designing for the proper support of rebar chairs isn’t just guesswork; it involves careful calculations to ensure the chairs can withstand the forces they’ll encounter. Here’s how we approach it:

- Dead Load (Rebar Weight): This is the static weight of the reinforcing steel itself. We calculate the weight of the rebar per unit length (e.g., in kN/m) and then determine the total weight of rebar that each chair will support based on its tributary area. For example, the weight of rebar (W) in kN/m can be derived using the formula W = (10 * D^2) / 162,000, where D is the diameter of the rebar in mm.

- Live Load (Construction): This accounts for the dynamic loads during construction, including the weight of workers, equipment, and the wet concrete itself. A common live load to consider might be around 1.5 kN/m2, as referenced in some engineering guides, but always refer to ASCE-7 for specific live load considerations.

- Factored Load: To ensure a safety margin, we apply load factors to both dead and live loads. The factored load is typically calculated as (1.2 * Dead Load) + (1.6 * Live Load) as per ACI 318 guidelines. This factored load is what the chair must ultimately be able to support.

- Buckling Capacity (Euler’s Formula): For steel chairs, or even the rebar used to form chairs, we must check their buckling capacity. This is often done using Euler’s formula, which considers the chair’s material properties (like modulus of elasticity, typically 200,000 MPa for rebar), its cross-sectional properties (area moment of inertia), and its unsupported length. For example, a T25 rebar chair reinforcement with an unsupported length of 2.0m might have a maximum buckling force of 9.46 kN.

- Strength Reduction Factor (phi): As per ACI 318-14, a strength reduction factor (phi) is applied to the calculated buckling capacity to account for uncertainties in material properties, construction tolerances, and analysis methods. For buckling, this factor is typically less than 1.0 (e.g., 0.75). So, the allowable buckling force is (phi * Pcr).

- Example Calculation: For a heavy raft foundation, with specific top and bottom reinforcement, we might calculate a factored load of 2.85 kN/m2. If an allowable buckling force for a T25 reinforcement chair is 7.1 kN, the calculation might show a requirement of 1 T25 reinforcement chair per square meter. These detailed calculations ensure that our chairs are not just placed, but intelligently designed into the structure.

The Role of Chairs in Advanced Slab Systems

In more complex structural designs, such as two-way slab systems, the role of rebar chairs extends beyond simple elevation. Here, they are integral to the precise placement of reinforcement for critical elements like shear reinforcement.

- Shear Reinforcement: In two-way slab systems, particularly at slab-column connections, punching shear can be a significant concern. Shear reinforcement, often in the form of stirrups or headed studs, is crucial to resist these forces. While rebar chairs themselves don’t provide shear reinforcement, they are essential for holding these shear elements in their precise locations during the pour, ensuring they perform as designed. The ACI provides extensive guidance on this, including the Guide to Shear Reinforcement for Slabs, which details how punching shear can be effectively resisted by reinforcement consisting of vertical rods mechanically anchored at the top and bottom of slabs.

- Two-Way Slab Systems: These systems distribute loads in two directions, requiring a complex grid of reinforcement. Rebar chairs are indispensable for maintaining the correct spacing and cover for both top and bottom mats of reinforcement, ensuring the slab behaves as a single, integrated unit. For a deeper dive into the design of these complex systems, we recommend consulting the Guide to Design of Reinforced Two-Way Slab Systems.

- Punching Shear and Moment Transfer: At column connections in flat-plate floors, high shear stresses and moments are transferred between the columns and slabs. Proper placement of reinforcement, facilitated by rebar chairs, is vital to resist these forces and prevent catastrophic punching shear failures. Our chairs ensure that all reinforcing steel, including any specialized shear reinforcement, is exactly where it needs to be to handle these critical loads.

Frequently Asked Questions about Rebar Chairs

We often hear similar questions from our customers and partners. Here are some of the most common ones, answered directly to help you with your next project.

How many rebar chairs do I need per square meter?

As a general rule, plan for an average of 1 chair per square meter (or roughly 10 chairs per 100 sq ft), but always adjust based on rebar weight and project specifications. Heavier reinforcement requires closer spacing. This is a starting point, and we always encourage you to refer to your engineering drawings for precise requirements. Our Hercules Rebar Chair Estimator can also provide a more custom estimate for your specific needs.

What happens if you don’t use rebar chairs?

Without chairs, the rebar will sink to the bottom of the slab during the concrete pour. This eliminates the required concrete cover, exposing the steel to moisture and corrosion, which severely compromises the slab’s structural integrity and lifespan. It’s like building a house without a foundation – it simply won’t stand the test of time, leading to costly failures and potential safety hazards. The rebar needs to be correctly positioned to do its job, and chairs are the only reliable way to ensure this.

Can you use rocks or bricks instead of rebar chairs?

No, absolutely not! Rocks, bricks, or wood scraps are not acceptable substitutes for engineered rebar chairs. They are porous, have inconsistent heights, can absorb water, and can create weak points in the concrete. Furthermore, they do not meet building code requirements for proper reinforcement support. Using such makeshift supports can lead to non-compliant structures, premature failure, and significant liability. Always use purpose-designed, code-compliant rebar chairs for your concrete projects.

Conclusion: Building a Strong Foundation with the Right Support

In this extensive guide, we’ve explored the critical role of the chair in slab reinforcement, from its primary function in maintaining concrete cover to the intricate details of spacing, placement, and technical design. We’ve seen how these seemingly small components are, in fact, indispensable for ensuring the structural integrity, longevity, and safety of our concrete slabs.

The importance of using quality supports, adhering to precise spacing guidelines, and complying with industry standards cannot be overstated. By understanding the different types of chairs, the factors influencing their placement, and the common mistakes to avoid, we empower you to build stronger, more durable concrete structures.

At Hercules Rebar Chairs, we are dedicated to providing superior strength and reliability. Our chairs, identifiable by their iconic red color, are engineered to save you time and money on the job site by ensuring code compliance and preventing costly errors. We’re proud to be “America’s #1” choice, with millions of units sold, helping contractors across the nation build with confidence.

Don’t leave the strength of your concrete to chance. Ensure your next project is built to last by using the correct reinforcement supports. Learn more about us at About Hercules Rebar Chair and make the smart choice for your next pour. Buy Rebar Chairs today and experience the Hercules difference!