Why Steel Chairs for Rebar Are the Foundation of Quality Concrete Work

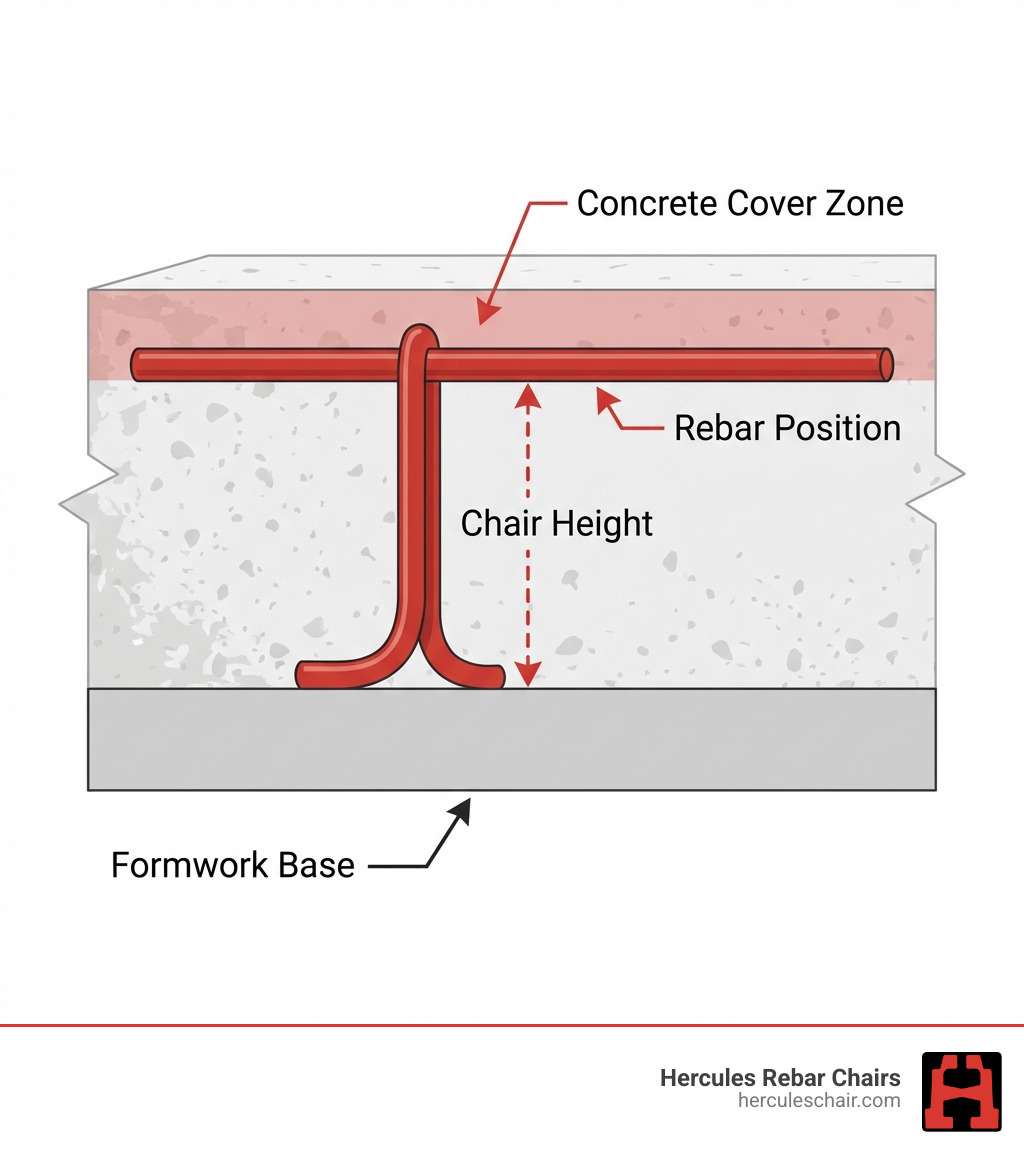

Steel chairs for rebar are wire or steel devices that lift and hold reinforcing bars (rebar) at the correct height within concrete formwork, ensuring proper concrete cover and structural integrity. They replace the time-consuming traditional method of tying rebar in place, providing consistent elevation and code-compliant placement for concrete pours in slabs, footings, and foundations.

Quick Answer – What You Need to Know:

- Primary Function: Lift rebar above formwork to maintain proper concrete cover (typically 3/4″ to 14″ height)

- Main Types: Individual high chairs, continuous chairs (bolsters), mesh chairs, and footer stands

- Key Materials: Bright basic steel, galvanized steel, epoxy-coated, or plastic-tipped for rust prevention

- Core Benefits: Faster installation than tying, consistent rebar placement, superior load-bearing strength, and code compliance

- Common Applications: Slabs-on-grade, liftd slabs, foundations, footings, tilt-wall panels, and precast concrete

If you’ve ever spent hours tying rebar with wire, only to watch it shift during the concrete pour, you understand the frustration. One contractor shared that after switching to steel chairs for rebar, they poured a garage slab with five workers standing directly on the chairs during placement—and the rebar didn’t move an inch. That’s the difference between guessing and knowing your concrete will cure correctly.

With over 14 million Hercules Rebar Chairs in use across America today, contractors have proven that the right support system saves both time and money while ensuring every pour meets code. The wide base prevents puncturing vapor barriers, the steel construction won’t crush under load, and repositioning rebar takes seconds instead of minutes of cutting and retying wire.

For concrete contractors, the question isn’t whether to use rebar chairs—it’s which type will work best for your specific project conditions. The wrong choice can mean sagging rebar, code violations, or structural problems that surface years later. The right choice means confidence in every pour.

What Are Steel Rebar Chairs and Why Are They Essential?

At its core, a steel rebar chair is a small but mighty component in concrete construction. Its primary function is deceptively simple: to lift and hold reinforcing bars (rebar) at a precise height within the concrete formwork. This seemingly minor task is, in fact, absolutely critical for the structural integrity and longevity of any concrete structure.

Imagine pouring concrete directly onto rebar lying on the ground. The rebar would sink, becoming ineffective. It needs to be suspended within the concrete matrix to work its magic. This elevation ensures what we call “concrete cover”—the minimum distance between the rebar and the surface of the concrete. Without adequate concrete cover, the rebar is exposed to moisture and oxygen, leading to corrosion. Corroding rebar expands, causing the concrete to crack and spall, ultimately compromising the entire structure.

Proper reinforcement placement, facilitated by steel chairs for rebar, means that the steel can effectively carry tensile loads, which concrete alone cannot. This prevents premature cracking and ensures that the structural components, whether a slab, a foundation, or a wall, can withstand anticipated stresses over their lifespan. By maintaining the correct position, these chairs contribute directly to the structural longevity and efficient load distribution throughout the concrete element. They are the unsung heroes that keep our concrete strong and sound for decades to come.

For readers who want a broader background on how reinforcing steel works with concrete in general, the overview on reinforced concrete is a useful reference alongside our product-specific resources.

How Rebar Chairs Improve Structural Integrity

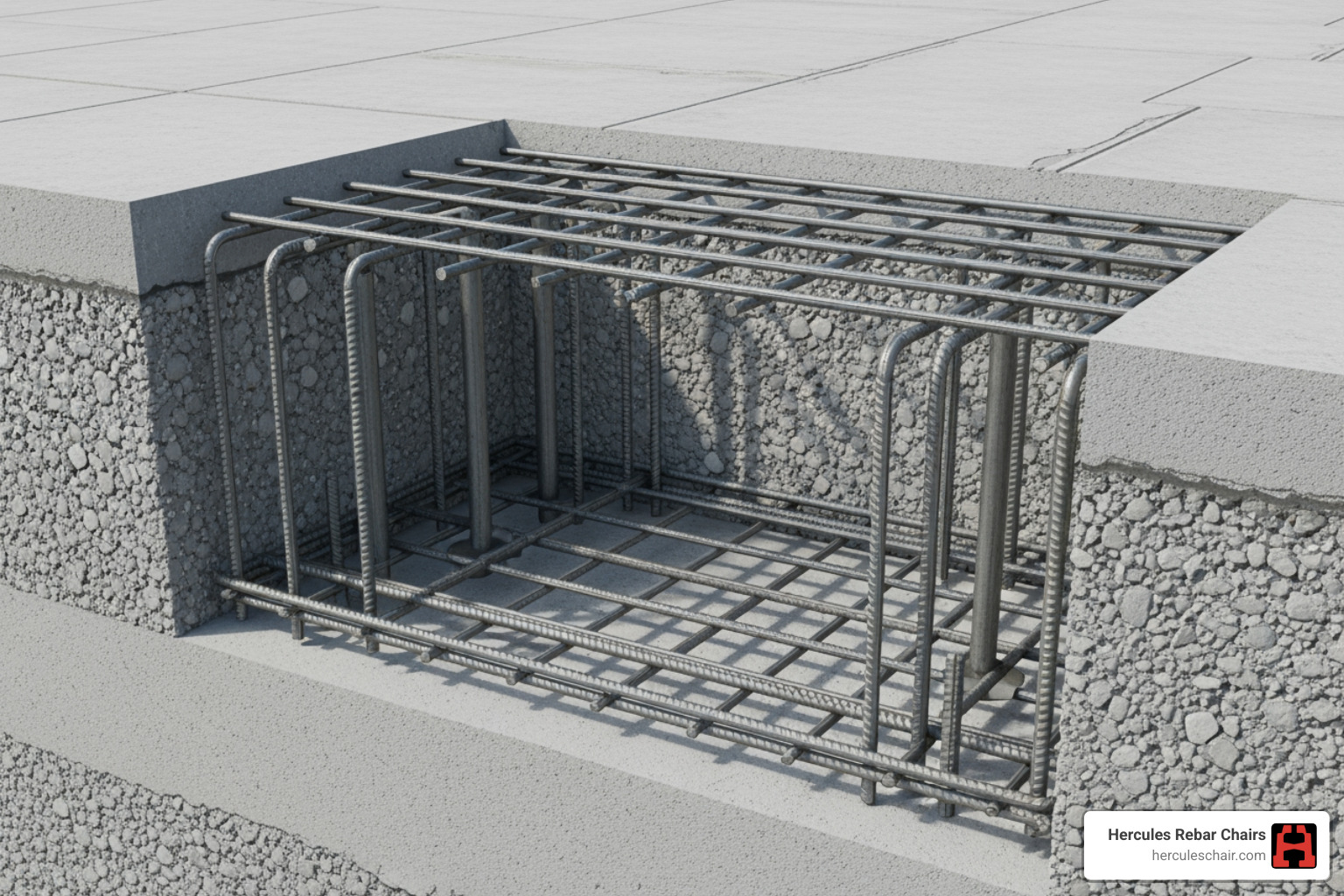

The impact of steel chairs for rebar on structural integrity cannot be overstated. When rebar is held at the proper depth, it is optimally positioned to resist tensile forces. This is crucial because concrete is strong in compression but weak in tension. The rebar provides the necessary tensile strength, working in conjunction with the concrete to create a robust composite material.

If rebar sags or is misplaced, its ability to resist these forces is compromised. This can lead to localized stress concentrations, increasing the likelihood of early cracking and potential structural failure. Steel chairs for rebar ensure uniform support, preventing such sagging and maintaining the designed rebar geometry throughout the pour. This precise placement is fundamental for the concrete to achieve its intended strength and for the overall structure to perform as designed, resisting everything from everyday wear and tear to seismic activity.

For a deeper dive into optimal rebar positioning, our Rebar Placement Guide offers valuable insights.

Exploring the Types of Steel Rebar Chairs

Just as there are many types of concrete projects, there are various types of steel chairs for rebar, each designed for specific applications and rebar configurations. Understanding these types helps us choose the right tool for the job.

Among our product line, you’ll find solutions for virtually any concrete reinforcement need. Let’s look at some common types:

- Individual High Chairs: These are single-point supports, often featuring a ‘Z’ top design for maximum strength and easy rebar tying. They are excellent for supporting upper steel directly or with a carrier bar, ensuring proper concrete coverage in flat slabs, liftd slabs, and precast panels. Some even come with a formed cradle design to hold reinforcing bars securely.

- Continuous High Chairs (Slab Bolsters): These are longer, continuous supports with multiple legs, designed to support rebar over a wider area. Slab bolsters are ideal for large slab applications, providing consistent elevation across extended spans. They are available in various heights, typically from 1″ to 6″ in 1/4″ increments, and come in standard lengths of 5 feet.

- Mesh Chairs: Specifically designed to support wire mesh reinforcement, these chairs often have a wider top to accommodate the mesh grid, ensuring it stays at the desired height within the concrete. Our 2-inch steel mesh chairs, for example, are robust solutions for mesh applications.

- Footer Stands: These are specialized chairs designed for foundation footings. They typically support multiple bars (e.g., 2-bar or 3-bar configurations) at a fixed height, ensuring the rebar cage for a footing is correctly positioned before the concrete pour.

You can explore our full range of solutions and their specific applications on our Our Products page.

Common Materials and Finishes

The choice of material and finish for steel chairs for rebar is crucial for their performance and durability, especially considering the harsh environments they often face.

- Bright Basic Steel: This is the most common and economical option. It’s plain steel wire, strong and effective for most general applications where corrosion is not a primary concern, or where the chair will be fully encased in concrete and not exposed to the elements.

- Galvanized Steel: For improved corrosion resistance, steel chairs can be galvanized. This process involves coating the steel with a layer of zinc, which acts as a sacrificial barrier, protecting the underlying steel from rust. This is often preferred in environments where moisture is prevalent.

- Epoxy-Coated: An epoxy coating provides an excellent barrier against corrosion, making these chairs suitable for more aggressive environments or when specific project specifications require superior rust protection.

- Plastic-Tipped: Many steel chairs for rebar come with plastic-tipped feet. This is particularly important when the chairs rest on a finished surface, such as a vapor barrier or formwork, to prevent rust stains on the concrete surface or punctures in membranes. The plastic tips ensure rust-free contact and protect sensitive surfaces.

These material choices ensure that our metal supports are not only strong but also adapted to diverse project needs, prolonging the life of the concrete structure by preventing rust bleed and maintaining structural integrity.

Common Applications for steel chairs for rebar

The versatility of steel chairs for rebar makes them indispensable across a wide range of concrete construction projects. Their ability to precisely position rebar is critical for success in many applications:

- Slabs-on-Grade: For ground-supported concrete slabs like garage floors, driveways, and patios, chairs ensure the rebar or mesh is centered within the slab, providing maximum strength.

- Liftd Slabs: In multi-story buildings, parking structures, and bridge decks, liftd slabs require precise rebar placement to handle complex loading conditions.

- Foundations: Whether for residential homes or commercial buildings, strong foundations are paramount. Chairs ensure that the rebar cage in footings and foundation walls is correctly positioned.

- Footings: Our 2-bar and 3-bar footer stands are specifically designed for these applications, ensuring the rebar in foundation footings is held securely at the correct height. See our 2 Bar Footer Stand and 3 Bar Footer Stand for examples.

- Tilt-Wall Panels: These precast concrete wall panels, often cast horizontally on-site and then tilted into place, demand exact rebar alignment. Plastic-dipped or plastic-tipped chairs are often used to prevent staining on exposed surfaces.

- Precast Concrete: In manufacturing facilities, precast concrete elements (beams, columns, wall panels) are produced under controlled conditions, where precise rebar placement using chairs is essential for quality and consistency.

These applications highlight how steel chairs for rebar are fundamental to achieving durable, code-compliant concrete structures, from the ground up to the highest elevations.

Why Choose Steel Rebar Chairs from Hercules?

When it comes to supporting the backbone of your concrete project, the choice of rebar chairs matters. While other support methods exist, we believe our steel chairs for rebar offer unparalleled advantages when compared to plastic chairs or traditional rebar tying:

- Strength: Hercules Steel Chairs provide superior strength and will not crush under load. In contrast, plastic chairs can deform or crush, and traditional wire tying often results in sagging rebar.

- Stability: Our chairs feature an excellent wide base for stability on soft surfaces. Plastic chairs can be unstable on soft ground, and wire tying is prone to shifting during the pour.

- Durability: Made from long-lasting steel, our chairs are highly durable. Plastic alternatives can become brittle over time.

- Load Capacity: Hercules chairs have a high load capacity, easily supporting heavy rebar and foot traffic. Plastic chairs have a low to moderate load capacity.

- Ease of Use: Our chairs are extremely easy to use, allowing for quick placement and adjustment. While plastic chairs are also quick to place, traditional wire tying is a time-consuming and tedious process.

- Temperature Resistance: Steel offers excellent stability in extreme heat and cold. Plastic chairs can warp in the heat and become brittle in the cold.

- Code Compliance: Our chairs are designed for precise cover, ensuring code compliance. Both plastic chairs and traditional tying can lead to inconsistent placement that is difficult to verify and may not meet all codes.

Our steel chairs for rebar are designed with the reality of construction sites in mind. They offer superior load-bearing capacity, meaning they won’t buckle or deform under the weight of heavy rebar or the foot traffic of crew members during a pour. This stability is crucial, especially when working on soft substrates or vapor barriers, where a wide base prevents sinking or puncturing. Unlike plastic alternatives, steel maintains its integrity across extreme temperature fluctuations, ensuring consistent performance whether it’s a scorching summer day or a freezing winter morning.

This robust performance translates directly into time savings and reduced labor costs. Imagine the efficiency gained when your crew isn’t constantly re-adjusting sagging rebar or re-tying connections. It’s a game-changer for project timelines and budgets.

Advantages of Hercules Steel Chairs

The advantages of choosing our steel chairs for rebar are clear and impactful, contributing significantly to project success and peace of mind.

- Superior Strength: Our chairs are engineered to withstand substantial loads. This means your rebar stays precisely where you put it, even under the weight of heavy rebar mats or the inevitable foot traffic during concrete placement. We are proud of our “strongest rebar products” claim, backed by over 25 years of design and production experience.

- No Crushing Under Load: Unlike some alternatives that can deform or crush, our steel construction maintains its height, ensuring that the critical concrete cover is consistently achieved. This is vital for meeting structural specifications and preventing long-term issues.

- Stability in Hot Weather: Plastic chairs can soften and deform in high temperatures, leading to rebar sag. Steel remains rigid and stable, providing reliable support regardless of the weather conditions on your job site.

- Longevity: Made from durable steel, our chairs are built to last. While their primary job is temporary support during the pour, their inherent durability speaks to the quality of the product.

Benefits Over Traditional Rebar Tying

For decades, tying rebar with wire has been the standard practice. However, our steel chairs for rebar offer significant benefits that streamline the process and improve the quality of your concrete work.

- Speed of Installation: One of the most immediate benefits is the drastic reduction in setup time. Instead of laboriously tying every intersection, our chairs allow for rapid placement of rebar, saving precious hours on the job site. Contractors report significant time savings compared to traditional tying.

- Consistent Height: Achieving uniform concrete cover is effortless with our chairs. Each chair is manufactured to a precise height, guaranteeing that your rebar is consistently liftd, which is difficult to achieve with manual tying.

- Easy Adjustments: Sometimes, rebar needs to be repositioned. With traditional tying, this means cutting and re-tying. Our chairs allow for easy repositioning by simply unsnapping and relocating the rebar, saving time and frustration.

- Reduced Labor: The combined effect of faster installation and easier adjustments leads to a substantial reduction in labor requirements. This frees up your crew for other critical tasks, optimizing project efficiency.

- Code Compliance: Our products are designed to ensure your concrete pour always meets code requirements. The precise and consistent placement of rebar is a fundamental aspect of code compliance, and our chairs provide that assurance.

Our customers frequently share positive feedback, highlighting the ease of use and time savings our chairs provide. Read what they’re saying and see for yourself on our About Hercules Rebar Chair / Reviews page.

How to Select the Right Steel Rebar Chairs for Your Project

Choosing the correct steel chairs for rebar is a critical step that directly impacts the success and longevity of your concrete structure. It’s not a one-size-fits-all situation; careful consideration of your project’s unique specifications is essential.

First, always consult your project’s blueprints and engineering specifications. These documents will explicitly state the required concrete cover for your rebar, the size of the rebar being used, and often, the type of support system. The rebar size (e.g., #3, #4, #5) will dictate the slot size needed in the chair. The required concrete cover directly translates to the necessary chair height. For instance, if your specifications call for a 2-inch concrete cover, you’ll need chairs that lift the rebar 2 inches from the formwork.

Load capacity is another vital factor. For heavily reinforced slabs or areas expecting significant foot traffic during the pour, you’ll need chairs designed to withstand greater weight without deforming. We offer various options to accommodate different load requirements.

To help you steer these choices, our Hercules Rebar Chair Estimator can assist in determining the right chairs and quantities for your project. You can also review our full range of Rebar Supports & Accessories to find the perfect fit.

Key Features to Consider in steel chairs for rebar

When making your selection, several key features of steel chairs for rebar deserve your attention:

- Chair Height: This is perhaps the most critical feature, directly corresponding to the specified concrete cover. Chairs are available in a wide range of heights, typically from 3/4 inch to 14 inches, often in 1/4-inch increments, allowing for precise elevation.

- Base Design: The design of the chair’s base is crucial for stability and protection of underlying surfaces. A wide, stable base is ideal for soft ground or when placing chairs on vapor barriers, preventing punctures and ensuring the chair doesn’t sink. Our wide-based chairs are specifically designed to protect vapor barriers, as highlighted on our Vapor Barrier Mat page.

- Vapor Barrier Protection: If your project involves a vapor barrier, choosing chairs with a design that minimizes puncture risk is paramount. Our chairs are designed with wide bases to spread the load and prevent damage to these critical membranes.

- Load Capacity: As mentioned, consider the weight of the rebar, any subsequent layers, and the anticipated foot traffic. Heavy-duty options are available for demanding applications.

- Material Finish: For projects where rust staining is a concern (e.g., exposed concrete surfaces) or in corrosive environments, select chairs with protective finishes like galvanization, epoxy coating, or plastic-tipped feet. Our 2 Inch Steel Mesh Chair Product 944 is an example of a robust support designed for various applications.

Understanding Industry Standards and Spacing

Adhering to industry standards and proper spacing guidelines is not just good practice; it’s essential for structural integrity and code compliance. In the United States, the American Concrete Institute (ACI) specifications and Concrete Reinforcing Steel Institute (CRSI) standards are the primary authorities governing concrete reinforcement.

These standards provide detailed requirements for rebar placement, concrete cover, and the use of rebar supports. Our steel chairs for rebar are designed to help you meet these specifications, ensuring your project is always code-compliant. For instance, chairs over 12 inches in height often require cross bracing or lacing of legs for added stability, a detail we take into account in our product designs.

Regarding spacing, while specific requirements vary based on the rebar size, slab thickness, and load, general guidelines suggest that chairs should be spaced to prevent rebar sag and maintain consistent cover. For example, for some applications, a recommended spacing of around 5 feet apart for supports is common. However, always refer to your project’s specific plans and our detailed product data sheets, available in our Resources / Data Sheet section, for precise spacing recommendations. Proper spacing ensures uniform support and prevents rebar from shifting during the concrete pour, contributing to a stronger, more durable finished product.

Frequently Asked Questions about Steel Rebar Chairs

We understand you might have more questions about these essential components. Here are some of the most common inquiries we receive:

How far apart should you space rebar chairs?

The optimal spacing for steel chairs for rebar is not a fixed number; it depends on several factors:

- Rebar Size and Weight: Heavier rebar (larger diameter) or multiple layers of rebar will require closer spacing to prevent sagging.

- Slab Thickness: Thicker slabs generally allow for slightly wider spacing, but the overall load still needs to be considered.

- Load on Rebar: If workers will be walking on the rebar mat before the pour, or if heavy equipment will be used nearby, closer spacing will be necessary to prevent deformation.

- Project Specifications: Always refer to your project’s engineering drawings and ACI guidelines. These documents will often provide specific spacing requirements.

- Manufacturer Recommendations: Our product data sheets and guides offer specific spacing recommendations for our chairs. For example, our Footer Stand Placement Guide provides detailed instructions for optimal use of our footer stands.

As a general rule, chairs should be spaced closely enough to prevent any noticeable sag in the rebar between supports. A common guideline might be 3 to 5 feet apart, but this can vary significantly. When in doubt, err on the side of closer spacing to ensure maximum support and compliance.

Do steel rebar chairs cause rust spots in the concrete?

This is a common concern, and the short answer is: typically no, if the correct type of steel chairs for rebar are used and they are properly encased in concrete.

The primary cause of rust spots (known as “rust bleed” or “rust staining”) occurs when metal components are too close to the concrete surface and moisture allows the metal to corrode, staining the concrete. To mitigate this:

- Proper Concrete Cover: The most crucial factor is ensuring the rebar chair is fully encapsulated within the concrete, maintaining the specified concrete cover. If the chair is adequately covered, it won’t be exposed to the elements that cause rust.

- Protective Finishes: For situations where chairs might be close to an exposed surface, or in particularly corrosive environments, we offer chairs with protective finishes:

- Plastic-Tipped Feet: These are excellent for preventing rust marks on the visible concrete surface, especially when the chair legs might otherwise be too close to the finish. The plastic creates a barrier, ensuring rust-free contact.

- Epoxy-Coated or Galvanized Wire: These coatings provide an additional layer of protection against corrosion for the entire chair, making them ideal for projects with strict aesthetic or durability requirements.

By selecting the appropriate chair finish and ensuring proper concrete cover, you can effectively prevent rust spots and maintain the aesthetic and structural integrity of your concrete.

What are the sustainability aspects of using steel rebar chairs?

In today’s construction landscape, sustainability is an increasingly important consideration. When it comes to steel chairs for rebar, there are several positive environmental aspects:

- Steel Recyclability: Steel is one of the most recycled materials globally. At the end of a structure’s life, the steel used in rebar and, by extension, steel chairs, can be recovered and recycled, reducing the demand for virgin materials and saving energy.

- Recycled Material Content: Many steel products, including rebar chairs, are manufactured using a significant percentage of recycled steel. This closed-loop system minimizes waste and conserves natural resources.

- Durability vs. Disposable Alternatives: While some plastic rebar chairs are made from recycled materials, steel chairs often offer superior durability and load-bearing capacity. Their robust nature means less chance of failure and replacement, contributing to a longer-lasting, more resilient structure. The longevity of the concrete structure itself, supported by reliable steel chairs, means less frequent reconstruction and associated environmental impact.

- USA Manufacturing: We are proud that our products are 100% made in the USA. This reduces the carbon footprint associated with long-distance transportation of goods from overseas, supporting local economies and adhering to stringent environmental regulations.

By choosing durable, high-quality steel chairs for rebar, we contribute to more sustainable construction practices, ensuring our projects are not only strong but also environmentally conscious.

Conclusion: Build with Confidence and Strength

The seemingly small detail of choosing the right steel chairs for rebar can have an outsized impact on the success and longevity of your concrete projects. We’ve seen how these “strong silent types” are fundamental to ensuring proper rebar placement, maintaining critical concrete cover, and ultimately, safeguarding the structural integrity of everything from humble patios to towering foundations.

By understanding the different types of steel chairs for rebar, their materials, and their applications, you’re empowered to make informed decisions that benefit your projects in multiple ways. The advantages are clear: superior strength and stability, significant time and labor savings compared to traditional tying methods, and the assurance of meeting crucial industry standards and building codes. We believe that when you choose our steel chairs for rebar, you’re not just buying a product; you’re investing in the confidence that comes with every pour.

For a proven solution trusted on millions of projects, explore the American-made Hercules Rebar Chair product line. Your next project deserves the best foundation, both literally and figuratively.