Why Concrete Cover Rebar Matters for Every Pour

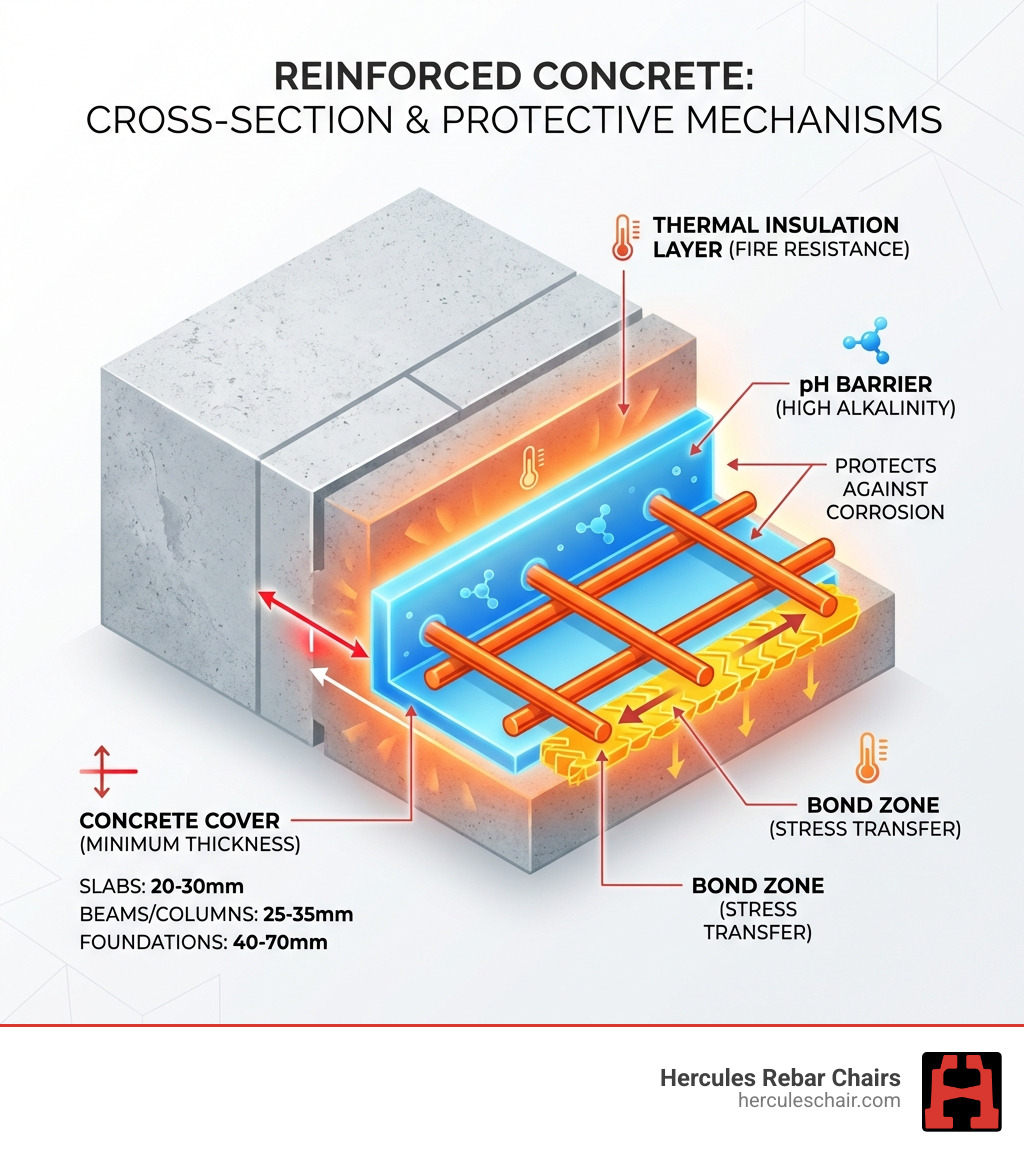

Concrete cover rebar is the distance between the outer surface of the concrete and the nearest surface of the embedded reinforcing steel. It’s not just a measurement—it’s the primary defense system that protects your rebar from corrosion, fire, and structural failure.

Quick Answer: What You Need to Know About Concrete Cover Rebar

- Definition: The minimum thickness of concrete surrounding and protecting reinforcing steel bars

- Primary Purpose: Protects rebar from corrosion, provides fire resistance, and ensures proper bond between steel and concrete

- Typical Requirements:

- Slabs: 20-30mm (dry to coastal)

- Beams/Columns: 25-35mm (dry to coastal)

- Foundations: 40-70mm (depending on soil contact)

- Key Risk: Inadequate cover can reduce a structure’s load capacity by 20% and lead to premature failure

- Critical Tool: Rebar chairs and spacers maintain proper positioning during concrete placement

Here’s what contractors face on every job: one contractor preparing a workshop floor wanted to use just 13/16 inch (about 20mm) of cover to save concrete. The response from experienced builders was swift—that’s far too little. Even a half-inch deviation in rebar placement can slash a slab’s load-carrying capacity by 20%.

The science is straightforward. Concrete naturally protects steel through its high pH level (around 12.5-13.5), which creates a passive layer on the rebar surface. But this protection only works when there’s enough concrete between the steel and the outside world. Without adequate cover, moisture, carbon dioxide, and chlorides from de-icing salts penetrate to the rebar. The steel corrodes, expands up to six times its original volume, and cracks the concrete from the inside out.

Different building codes worldwide recognize this critical relationship. ACI 318 in the USA specifies 40-75mm depending on exposure. Eurocode 2 ranges from diameter +10mm to 55mm. The Canadian CSA A23.1 requires 60mm minimum cover for concrete exposed to de-icing chemicals. These aren’t arbitrary numbers—they’re based on decades of structural performance data and failure analysis.

The challenge isn’t just knowing how much cover you need. It’s achieving it consistently on site, pour after pour, even when concrete flows around your carefully positioned rebar cage.

The “Why”: Primary Purposes of Concrete Cover

The steel reinforcement, or rebar, embedded within concrete is the backbone of modern construction. While concrete excels in compression, it’s relatively weak in tension. Rebar steps in to handle these tensile forces, preventing cracks and ensuring structural integrity. However, rebar itself needs protection. This is where concrete cover rebar comes into play, serving several crucial purposes that contribute to the longevity, safety, and performance of any concrete structure. For more on the fundamental aspects of concrete cover, you can refer to The Constructor’s guide on concrete cover for reinforcement.

Corrosion Protection: The Chemical Shield

One of the most vital roles of concrete cover rebar is to act as a chemical shield against corrosion. Steel is naturally susceptible to rust when exposed to oxygen and moisture. Fortunately, the alkaline environment of concrete provides a powerful defense.

Initially, fresh cement water boasts a high pH of about 13.5. Even as the concrete ages, its interstitial water maintains a pH around 12.5. This highly alkaline environment creates a passive, protective layer on the surface of the steel rebar, preventing oxidation. As long as the pH remains above 10.5, the rebar is effectively “passivated” and safe from corrosion.

However, this protective shield can be compromised by two primary threats:

- Carbonation: Carbon dioxide from the atmosphere diffuses into the concrete, reacting with the hydrated cement paste. This process, known as carbonation, gradually lowers the concrete’s pH. If the pH drops below 10.5 to 9.5, the passive layer on the rebar breaks down, leaving the steel vulnerable to rust. A sufficient thickness of concrete cover rebar significantly slows down this carbonation process, extending the rebar’s protected lifespan.

- Chloride Ingress: Chlorides, often from de-icing salts, saltwater in coastal areas, or certain industrial chemicals, can penetrate the concrete and reach the rebar. These chlorides actively destroy the passive layer, even at high pH levels, triggering localized corrosion. This is why areas exposed to de-icing salts or marine environments require substantially thicker concrete cover rebar.

Once corrosion begins, it’s a destructive cycle. Iron corrosion products (rust) expand up to six times their original volume. This expansion creates immense internal pressure within the concrete, leading to cracking, spalling (pieces of concrete breaking off), and delamination. This not only weakens the structure but also provides easier pathways for more aggressive agents to reach the rebar, accelerating deterioration and ultimately leading to premature structural failure.

Fire Resistance: Insulating the Steel Core

Beyond corrosion, concrete cover rebar is a critical component of a structure’s fire resistance. Steel loses a significant portion of its strength at liftd temperatures. When a concrete structure is exposed to fire, the rebar inside can quickly heat up, potentially leading to its yield strength being compromised and the structural element failing.

The surrounding concrete acts as a thermal insulator. The thickness of the concrete cover rebar directly correlates with how long it takes for the rebar to reach critical temperatures during a fire. A thicker cover means more insulation, providing engineers and fire departments with crucial time to evacuate buildings and control the blaze. This insulation helps maintain the rebar’s structural integrity for a longer period, preventing premature collapse and enhancing overall building safety.

Bond and Structural Integrity

The strength of reinforced concrete relies heavily on the effective transfer of stress between the concrete and the embedded rebar. This stress transfer is facilitated by the bond between the two materials. Concrete cover rebar plays a crucial role in ensuring this bond remains strong and effective.

Modern rebar is typically “deformed,” meaning it has ribs or indentations along its surface. These deformations provide mechanical anchoring, significantly improving the bond with the concrete. Adequate cover ensures that there is enough concrete surrounding the rebar to allow this mechanical interlock to develop fully and to prevent the rebar from slipping under tensile loads.

Without sufficient cover, the concrete surrounding the rebar might be too thin to withstand the localized stresses generated during load transfer, leading to bond failure. Proper cover ensures that the rebar can be stressed without slipping, allowing the composite material to carry the intended load and contribute to the overall load-bearing capacity and ductility of the structure.

How Much is Enough? Factors Influencing Concrete Cover Rebar Thickness

Determining the appropriate thickness of concrete cover rebar isn’t a one-size-fits-all situation. It’s a carefully calculated decision based on a multitude of factors, all aimed at optimizing the long-term performance and safety of the structure. These factors include the environmental conditions the structure will face, the type of structural element, the specific building codes governing the region, the quality of the concrete used, and even the size of the rebar itself.

Environmental Exposure Conditions

The external environment is perhaps the most significant factor influencing concrete cover rebar requirements. The more aggressive the environment, the thicker the cover needs to be.

- Dry Climates: In dry, non-aggressive indoor environments or arid regions with minimal moisture, the risk of corrosion is lower, and minimum cover requirements can be less stringent.

- Coastal Areas and De-icing Salts: Areas exposed to saltwater spray or frequent application of de-icing salts on roads and bridges introduce chlorides, a major catalyst for rebar corrosion. In such aggressive conditions, significantly thicker concrete cover rebar is mandated. For instance, the Canadian CSA A23.1 standard stipulates a minimum of 60 mm (approximately 2.4 inches) of concrete cover rebar for elements exposed to chlorides from de-icing chemicals.

- Marine Environments: Structures submerged in or consistently exposed to seawater, such as piers, docks, and offshore platforms, face extreme corrosive conditions. Specialized codes like ACI 357 (for marine structures) often prescribe very generous cover depths and may necessitate corrosion-resistant rebar.

- Water Treatment Plants and Aggressive Chemicals: Structures in industrial settings, particularly water treatment plants (governed by codes like ACI 350), may be exposed to various corrosive chemicals. These applications demand increased concrete cover rebar and often specialized concrete mixes or protective coatings.

Minimum Concrete Cover Rebar Requirements by Structural Element

Different structural elements have varying functions, exposure levels, and load conditions, which influence their minimum concrete cover rebar requirements. Generally, elements directly exposed to the ground or weather require more cover than those protected indoors.

Here’s a general overview of typical minimum requirements, though specific project designs and local codes (like ACI 318) must always be consulted:

| Structural Element | Exposure Condition | Typical Minimum Cover (mm) | Typical Minimum Cover (inches) |

|---|---|---|---|

| Slabs | Dry climate | 20 | ~0.8 |

| Slabs | Seaside location | 30 | ~1.2 |

| Beams | Dry climate | 25 | ~1.0 |

| Beams | Seaside location | 35 | ~1.4 |

| Columns | Dry climate | 25 | ~1.0 |

| Columns | Seaside location | 35 | ~1.4 |

| Foundations | On lean concrete | 40 | ~1.6 |

| Foundations | Direct contact soil | 70 | ~2.8 |

| Walls (CSA C-1) | Exposed to chlorides | 60 | ~2.4 |

Note: These values are illustrative. Always refer to current building codes and project specifications.

The American Concrete Institute (ACI) 318 is the primary reference for clear cover in the USA. It differentiates requirements based on exposure and whether the concrete is cast-in-place or precast:

- Concrete cast against and permanently exposed to earth: ACI 318 typically requires 3 inches (approximately 75 mm) for all reinforcement, including bundled bars.

- Concrete exposed to earth or weather (cast-in-place):

- #6 through #18 bars: 2 inches (approximately 50 mm)

- #5 bars and smaller: 1½ inches (approximately 38 mm)

- Concrete not exposed to weather or in contact with ground (cast-in-place):

- Slabs, walls, joists: #14 and #18 bars: 1½ inches (approximately 38 mm); #11 bars and smaller: ¾ inch (approximately 19 mm)

- Beams and columns (primary reinforcement, ties, stirrups): 1½ inches (approximately 38 mm)

- Precast concrete manufactured under plant control conditions may have slightly different, often reduced, cover requirements due to tighter quality control. For example, for #11 bars and smaller in slabs, walls, and joists not exposed to weather, precast might require ⅝ inch (approximately 16 mm) cover.

A Global Perspective: Comparing Building Codes

While we primarily focus on practices applicable to our operations across the United States, it’s insightful to understand how different national building codes approach concrete cover rebar. These codes reflect local environmental conditions, construction practices, and safety philosophies.

- ACI 318 (USA): As mentioned, ACI 318 is the leading standard in the United States, with cover requirements generally ranging from 40-75 mm (approximately 1.5 to 3 inches) depending on exposure conditions, bar size, and member type.

- CSA A23.1 (Canada): This standard, often referenced in conjunction with US practices, specifies concrete cover rebar based on exposure classification. For instance, for a concrete wall with a CSA C-1 exposure classification (indicating exposure to de-icing chemicals), the minimum required cover for rebar on both faces would be 60 mm (approximately 2.4 inches).

- Eurocode 2 (EU): European standards often define cover as the bar diameter plus an additional value, typically ranging from diameter +10 mm to 55 mm.

- BS 8110 (UK): The British standard specifies a range for concrete cover rebar from 25-50 mm.

These variations highlight the importance of adhering to the specific building codes and engineering standards applicable to your project’s location.

The Risks of Getting It Wrong

Ignoring the prescribed concrete cover rebar is akin to building a house on sand. It might stand for a while, but its long-term stability and safety are severely compromised. Inadequate cover isn’t just a minor oversight; it’s a critical flaw that can lead to a cascade of problems, from expensive repairs to catastrophic structural failure.

Consequences of Inadequate Cover

The consequences of insufficient concrete cover rebar are far-reaching and detrimental:

- Corrosion Initiation: Without enough concrete to delay the ingress of moisture, oxygen, CO2, and chlorides, the rebar’s protective passive layer quickly breaks down. Corrosion begins prematurely, often years before it should.

- Cracking and Spalling: As the rebar rusts, it expands, exerting internal pressure on the surrounding concrete. This pressure causes the concrete to crack, first as hairline fissures, then as larger cracks, eventually leading to spalling. This exposes more rebar to the elements, accelerating the corrosion cycle.

- Reduced Load Capacity: Corroded rebar loses cross-sectional area and, consequently, its tensile strength. This directly reduces the load-carrying capacity of the structural element. As noted, a mere ½-inch deviation in rebar placement in a 6-inch slab can reduce its load-carrying capacity by 20%.

- Aesthetic Damage: Cracked, spalled, and rust-stained concrete is visually unappealing and signals structural distress, impacting property values and public perception.

- Compromised Structural Integrity: Severe corrosion and loss of bond between rebar and concrete lead to a compromised structural integrity, making the entire structure unsafe and potentially leading to collapse.

- Costly Repairs and Reduced Service Life: Repairing corroded structures is complex and expensive, often involving chipping away damaged concrete, cleaning or replacing rebar, and applying new concrete or protective coatings. In many cases, the structure’s service life is drastically reduced, requiring earlier replacement or demolition.

The Cover Paradox: Too Much of a Good Thing?

While the mantra is often “more cover is better,” there’s an interesting engineering paradox associated with concrete cover rebar: can it be too thick? Yes, in certain situations, particularly for flexural members (like beams and slabs) where cracking is expected under load.

Large cover depths (e.g., 50–75 mm or 2-3 inches) are indeed excellent for protecting reinforcement against corrosion in aggressive environments. However, research and observation have shown that excessively thick cover can lead to increased crack widths in flexural reinforced concrete members. The closer the reinforcement is to the surface, the smaller the surface crack widths will be, as the rebar can more effectively restrain the concrete. Conversely, if the rebar is too far from the surface, the cracks can become wider.

Cracks wider than 0.3 mm (approximately 0.012 inches) can permit the ingress of moisture and chemical attack, ironically defeating some of the benefits of a thick cover by creating pathways for aggressive agents to reach the rebar. This means that while the rebar might be deeply buried, the wider surface cracks could still allow corrosion to initiate.

Addressing this paradox involves a balanced approach:

- Optimizing Cover Thickness: Engineers must carefully balance corrosion protection with crack control.

- High-Quality Concrete: Using concrete with a low water-to-cement ratio results in lower porosity and reduced permeability, making it harder for corrosive agents to penetrate, even through cracks.

- Corrosion-Resistant Rebar: In highly aggressive environments, specifying stainless steel rebar, epoxy-coated rebar, or fiber-reinforced polymer (FRP) rebars can allow for reduced cover while maintaining durability.

- Effective Rebar Supports: Ensuring the rebar is precisely placed and held firm by quality supports helps achieve the intended cover and crack control.

For more detailed information on this topic, refer to the Wikipedia article on concrete cover.

On-Site Execution: Ensuring Proper Cover During Construction

Knowing the correct concrete cover rebar is one thing; achieving it reliably on a construction site is another. This requires meticulous workmanship, stringent quality control, and the right tools. The best designs can be undermined by poor execution, leading to costly failures down the line. We understand this challenge, which is why we focus on providing solutions that make achieving proper cover straightforward and reliable. You can find more practical guidance on placing reinforcing steel correctly.

The Role of Rebar Chairs and Spacers in a Proper Concrete Cover Rebar

The primary method for maintaining the correct position of concrete cover rebar during construction is through the use of specialized supports: rebar chairs and spacers. These unassuming devices are absolutely critical. They ensure that the rebar cage remains at the precise height and location specified in the design drawings, preventing it from sinking to the bottom of the formwork or being displaced during the concrete pour.

We pride ourselves on manufacturing strong rebar chairs and concrete supports designed for durability and precision. Our chairs are engineered to hold rebar firmly in place, ensuring that the specified concrete cover rebar is achieved every time. It’s crucial to use supports that are themselves non-corrosive and durable, which is why plastic rebar chairs are often preferred. Steel rebar spacers, for example, are generally discouraged or even forbidden in many applications because they are susceptible to corrosion. If a steel spacer rusts, it can cause spalling and staining, defeating the very purpose of the cover it’s meant to maintain.

Our products are designed to save time and money on the job site by simplifying accurate rebar placement, ensuring code compliance, and contributing to the overall longevity of your structures. You can explore our range of high-quality supports on our Our Products page.

Best Practices for Rebar Placement

Achieving the correct concrete cover rebar goes hand-in-hand with best practices for rebar placement:

- Tying Rebar Intersections: Rebar should be placed every 45-60 cm (18-24 inches) in both directions and tied at every second intersection. This creates a rigid cage that is less likely to deform during concrete placement. Typically, 16½- or 16-gauge tie wire is used, with heavier gauges for larger rebar.

- Support Spacing: Rebar chairs and spacers must be placed at appropriate intervals to prevent sagging. For slabs, spacers are often placed approximately every 1.00 meter (3.3 feet). The spacing will vary depending on the rebar size and stiffness of the cage. Our Rebar Placement Guide offers detailed recommendations.

- Avoiding “Hooking”: A common, but unacceptable, practice is to lay rebar directly on the subgrade and then “hook” or pull it up into position as the concrete is poured. This leads to inconsistent and inadequate concrete cover rebar. Rebar must be supported from below before concrete placement begins.

- ACI 117 Tolerances: Adhering to standards like ACI 117 for concrete construction tolerances is essential. While these tolerances allow for some deviation (e.g., ±3 inches for longitudinal bar position, provided cover and bar count are maintained), the goal is always to achieve the specified placement as accurately as possible to avoid reducing load capacity.

Special Considerations for Harsh Environments

In particularly harsh environments, achieving and maintaining concrete cover rebar becomes even more critical.

- Marine Structures: For structures in marine environments, such as those covered by ACI 357, significantly increased concrete cover rebar requirements are common. This is due to the constant exposure to chlorides and the corrosive nature of saltwater. Often, these applications also call for specialized concrete mixes and/or corrosion-resistant rebar like stainless steel.

- Water Treatment Plants: Structures in water treatment plants, often governed by ACI 350, face exposure to various aggressive chemicals. These environments necessitate not only increased concrete cover rebar but also careful selection of concrete materials and reinforcement types to resist chemical attack.

- Durable, Non-Corrosive Supports: In these aggressive settings, the choice of rebar supports is paramount. Any support material that can corrode or degrade will compromise the entire system. This underscores the importance of using high-quality, non-corrosive plastic supports that can withstand the specific environmental challenges.

Frequently Asked Questions about Concrete Cover

What happens if rebar cover is too thin?

If the concrete cover rebar is too thin, the rebar is left vulnerable to its worst enemies: moisture, oxygen, carbon dioxide (leading to carbonation), and chlorides (from de-icing salts or marine environments). This vulnerability allows corrosion to initiate rapidly. As the rebar rusts, it expands significantly—up to six times its original volume. This expansion creates immense internal pressure within the concrete, causing it to crack and spall (break off in pieces). This not only exposes more rebar to corrosive agents, accelerating the damage, but also severely compromises the structure’s strength, reduces its load-carrying capacity, and drastically shortens its service life.

Can concrete cover be too thick?

Yes, surprisingly, concrete cover rebar can be too thick, especially in certain types of structural elements like beams and slabs that are designed to flex under load. This is known as the “cover paradox.” While a very thick cover provides excellent corrosion protection for the rebar itself, it can lead to wider surface cracks in the concrete when the member deflects. The further the rebar is from the concrete surface, the less effectively it can restrain these cracks. Cracks that are too wide (e.g., greater than 0.3 mm) can act as direct pathways for moisture, chlorides, and CO2 to penetrate deep into the concrete, potentially reaching the rebar despite its deep embedment. This can, in effect, defeat the purpose of the thick cover by allowing aggressive agents to bypass the protective layer through the cracks.

How is the correct concrete cover maintained during construction?

The correct concrete cover rebar is maintained during construction through the diligent use of specialized rebar supports, primarily rebar chairs and spacers. These devices are strategically placed throughout the rebar cage before concrete is poured. Rebar chairs are typically used for horizontal reinforcement (like in slabs and footings) to lift the rebar to the precise height required for the specified cover. Spacers, often wheel-shaped or linear, are used for vertical reinforcement (like in columns and walls) to maintain the correct distance from the formwork. These supports ensure that the rebar cage remains stable and in its designed position, preventing it from sinking, shifting, or coming into contact with the formwork during the often-turbulent process of concrete placement and vibration. It’s crucial to use high-quality, durable, and non-corrosive supports to ensure the cover is maintained effectively throughout the life of the structure.

Conclusion

The importance of concrete cover rebar cannot be overstated. It is the silent guardian of our infrastructure, protecting the steel reinforcement that gives concrete its incredible strength and durability. From shielding rebar against corrosive elements like moisture and chlorides to insulating it from the devastating heat of fire, adequate cover is fundamental to the longevity, safety, and structural integrity of every reinforced concrete project.

Achieving the correct concrete cover rebar requires meticulous design, adherence to stringent building codes, and flawless execution on the job site. This means understanding the specific environmental conditions, the type of structural element, and the precise requirements of codes like ACI 318 and CSA A23.1. It also means recognizing the critical role of quality control and the tools that make it possible.

For us, ensuring proper concrete cover rebar is at the heart of what we do. We believe that using quality supports is key to achieving specified cover, protecting your investment, and building structures that stand the test of time. Our Hercules Rebar Chairs are engineered to be America’s #1 choice, helping contractors save time and money while ensuring code compliance and delivering superior results. When you choose our red chairs, you’re choosing reliability and peace of mind for every pour.

Ready to ensure your next project benefits from superior concrete cover rebar? Explore our range of high-quality rebar chairs and supports. Buy Rebar Chairs directly from us and build with confidence.