Why Concrete Foundation Rebar is the Backbone of Structural Integrity

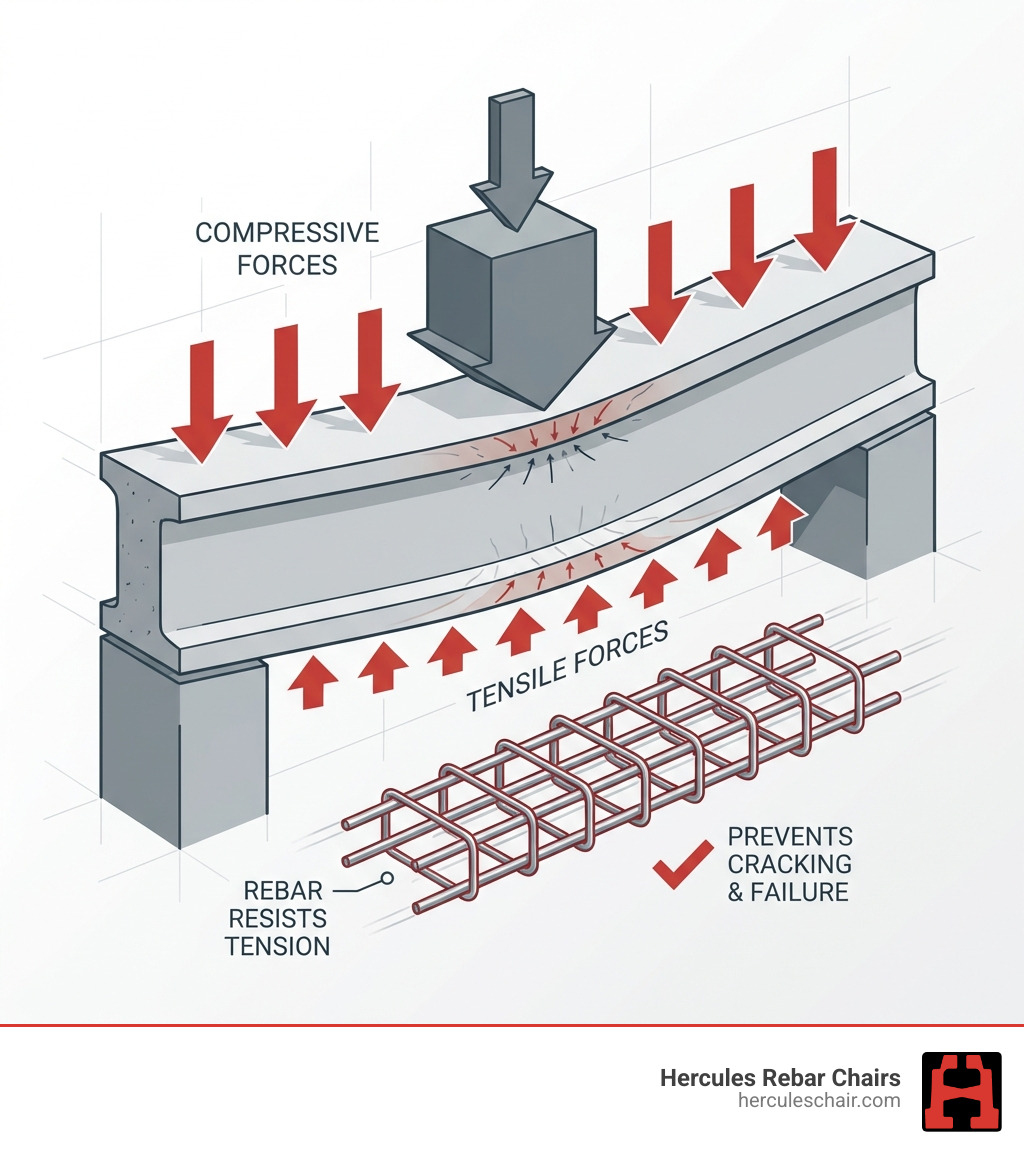

Concrete foundation rebar is essential because concrete, while incredibly strong under compression, is weak in tension—possessing only 10-15% of its compressive strength when pulled or bent. Rebar (reinforcing bar) solves this critical weakness by providing the tensile strength concrete lacks, changing it into a composite material that can withstand the complex forces acting on foundations.

Quick Answer: Key Facts About Concrete Foundation Rebar

- Purpose: Provides tensile strength to concrete, which is naturally weak under tension

- Common Sizes: #3 (3/8″), #4 (1/2″), #5 (5/8″) for residential foundations

- Standard Spacing: Typically 12 inches on center (O.C.) for residential footings

- Concrete Cover: Minimum 3 inches for footings, 1.5-2 inches for walls

- When Required: Structural elements, heavy loads, poor soil, slabs over 5 inches deep

Think of rebar as the skeleton inside your foundation. Just as your bones give your body structure and bear loads your skin and muscles cannot, rebar gives concrete the internal framework it needs to resist bending, cracking, and settlement over decades of service.

Without proper reinforcement, a concrete foundation is brittle. It may look solid, but under stress—from soil movement, building loads, or freeze-thaw cycles—it will crack and fail far sooner than it should. Rebar transforms that brittle material into something ductile and resilient.

The difference is dramatic. Research shows that concrete with rebar has a breaking point nearly double that of plain concrete. More importantly, reinforced concrete shows warning signs (small cracks) before failure, while unreinforced concrete can fail suddenly and catastrophically.

But here’s the critical part: rebar only works if it’s placed correctly. The wrong size, improper spacing, insufficient concrete cover, or displacement during pouring can turn your reinforcement from an asset into a liability. Even small errors matter—placing rebar just half an inch off its intended position in a 6-inch slab can reduce its load-carrying capacity by 20%.

That’s why understanding the fundamentals of rebar placement isn’t just technical knowledge—it’s the foundation (literally) of building structures that last.

The Blueprint: Planning Your Concrete Foundation Rebar

Before a single drop of concrete is poured, careful planning and selection of your concrete foundation rebar are essential. This initial blueprint sets the stage for the entire project’s structural integrity and longevity.

Choosing the Right Type of Concrete Foundation Rebar

When it comes to reinforcing your foundation, not all rebar is created equal. We have several types available, each with its own advantages, especially concerning corrosion resistance and cost.

The most common type we encounter is Carbon Steel Rebar, often called “black bar.” It’s incredibly versatile and widely used in construction across the USA. However, it’s susceptible to corrosion, which makes it less ideal for areas with high humidity or frequent water exposure.

For situations demanding higher corrosion resistance, we turn to specialized options:

- Epoxy-Coated Rebar: This is carbon steel rebar coated with a thin layer of epoxy. It’s significantly more resistant to corrosion—up to 1,700 times more than standard carbon steel—making it excellent for foundations in contact with saltwater or where corrosion is a major concern.

- Galvanized Rebar: Coated with zinc, galvanized rebar offers about 40 times the corrosion resistance of black bar. It’s a good middle-ground option for many projects.

- Stainless Steel Rebar: While expensive (about eight times the price of epoxy-coated rebar), stainless steel rebar boasts exceptional corrosion resistance—up to 1,500 times more than black bars. We typically reserve this for the most extreme environments or projects with very long design lives.

- Glass-Fiber-Reinforced-Polymer (GFRP) Rebar: This non-metallic option is highly resistant to corrosion and lighter than steel. However, it’s also very costly, sometimes ten times the price of epoxy-coated rebar, and its mechanical properties differ from steel.

Here’s a quick comparison to help us decide:

| Rebar Type | Corrosion Resistance | Cost | Best Use Case |

|---|---|---|---|

| Carbon Steel | Low | Low | General construction, interior foundations, dry environments |

| Epoxy-Coated | High | Moderate | Marine environments, areas with de-icing salts, wet conditions |

| Galvanized | Moderate | Moderate-High | Moderate exposure to moisture or corrosive agents |

| Stainless Steel | Very High | Very High | Extreme corrosive environments, critical structures |

| Glass-Fiber-Polymer | Very High (non-metal) | Very High | Non-magnetic applications, highly corrosive environments |

Standard Sizes for Concrete Foundation Rebar

The size of the rebar we use is critical and directly relates to the loads our foundation will bear. In the US, rebar is sized using a numbering system, where the number indicates the bar’s diameter in eighths of an inch. So, a #3 bar is 3/8″ in diameter, a #4 is 4/8″ (or 1/2″), and a #5 is 5/8″.

For residential foundations, we commonly see:

- #3 bars (3/8″): Often used for smaller projects, such as driveways or patios.

- #4 bars (1/2″): Widely used in standard residential footings, walls, and columns. Generally, a minimum of two #4 bars are required for residential footings.

- #5 bars (5/8″): Employed for larger homes or commercial buildings, especially in footings and foundations that need to support heavier loads.

- #6 bars (3/4″) and larger: Typically reserved for commercial building footings, foundation walls, or structures with significant load requirements.

The specific size and quantity of concrete foundation rebar are determined by structural engineers, who consider factors like the building’s weight, soil conditions, and local building codes. Their specifications, detailed in blueprints, are our guiding stars.

When Is Rebar Reinforcement Necessary?

The question of “when” rebar is needed is crucial. While concrete is often perceived as an indestructible material, we know its Achilles’ heel: tensile stress. This fundamental weakness means that for any structural element, or where significant forces are at play, rebar is not just recommended—it’s essential.

We rely on rebar for:

- Structural Concrete: This includes virtually all building walls, foundations, footings, and columns. If a concrete element is designed to carry a load or transfer forces, it needs rebar.

- Heavy Loads: Any concrete surface expected to support substantial weight, such as large trucks, heavy machinery, or steady traffic (like in a driveway), requires rebar. For example, a driveway designed to support a family minivan might not need the heaviest rebar, but one for large trucks certainly does.

- Poor Soil Conditions: If our foundation is being laid on expansive soils, shifting ground, or soft subgrades, rebar becomes even more vital. It helps distribute loads and resist settlement and shifting, which can cause catastrophic foundation failure.

- Slabs Over 5 Inches Deep: For thicker slabs, especially those supporting heavy loads, rebar is generally recommended to control cracking and provide structural integrity.

- Footings and Foundation Walls: These are the backbone of any structure. Footings carry the building’s entire weight, distributing it evenly across the soil. Foundation walls transfer these loads from the structure to the footing. Both require rebar to handle the tensile, shear, and bending forces they constantly endure. As the experts at Gra-Rock remind us, it can be catastrophic if your concrete isn’t properly reinforced.

When in doubt, we always lean towards including rebar. It’s often “low-cost insurance” against future cracking and structural issues, making the concrete stronger and more durable in the long run.

The Critical Steps: Proper Rebar Placement and Spacing

Once we’ve selected the right type and size of concrete foundation rebar, the next crucial phase is its precise placement. This isn’t just about throwing steel into the forms; it’s a meticulous process that directly impacts the foundation’s performance.

Achieving Correct Rebar Spacing

The spacing of rebar within our foundation is a delicate balance. Too wide, and the concrete lacks the necessary tensile support, leading to weakness. Too close, and the concrete mix struggles to flow around the bars, creating voids and a poor bond. This can result in a “honeycomb” effect, compromising the composite strength of the reinforced concrete. Imagine trying to pour thick batter through a fine sieve—it just won’t work well!

A common rule of thumb for residential and light commercial footings is to space rebar 12 inches on center (O.C.). However, for larger or more heavily loaded footings, this spacing is often reduced to 6″ or 8″ O.C. For light-duty 4-inch slabs, 12 inches O.C. is also typical.

The specific spacing is determined by engineers based on:

- Footing Dimensions: Wider or deeper footings might require different spacing patterns.

- Load Considerations: Heavier loads necessitate closer rebar spacing to effectively distribute stress.

- Soil Conditions: Expansive or unstable soils often demand more robust reinforcement layouts.

Consequences of improper spacing are severe. As one source highlighted, if rebar is placed at 5-inch spacing rather than the specified 4-inch spacing, the product’s strength can be reduced by 20%. This shows how easily a foundation’s structural integrity can be compromised. We emphasize precision in every project. For more detailed guidance, our Rebar Placement Guide provides invaluable information.

The Importance of Concrete Cover

Concrete cover refers to the amount of concrete between the reinforcing steel and the surface of the concrete element. This seemingly simple detail is, in fact, the single most important factor in protecting our concrete foundation rebar from corrosion. It also ensures a proper bond between the steel and concrete, allowing the rebar to develop its full strength.

Think of it as a protective shield. Without adequate cover, moisture and corrosive agents can reach the steel, causing it to rust and expand. This expansion creates internal pressure, leading to cracking and spalling (concrete breaking away)—a process that can ultimately destroy the foundation. Proper cover also contributes to fire resistance, helping the steel maintain its strength longer in extreme heat.

Minimum concrete cover requirements vary depending on the foundation element and its exposure:

- Footings (permanently exposed to earth): A minimum of 3 inches of cover is needed for rebar cast against and permanently exposed to earth.

- Concrete Exposed to Weather or Earth (e.g., basement walls): For #6 bars and larger, a minimum of 2 inches of cover is required. For #5 bars or smaller, 1½ inches is needed.

- Concrete Not Exposed to Weather or Earth (e.g., interior slabs, walls, joists): For #14 and #18 bars, ½ inch apart is required. For beams and columns, no less than 1½ inches apart.

- Slabs: For a solid slab using #5 temperature-shrinkage bars, we lift the rebar horizontally by a minimum of 3 inches.

Maintaining this precise cover is where specialized tools come into play. Our Footer Stand Placement Guide offers practical advice for ensuring rebar is correctly liftd and positioned.

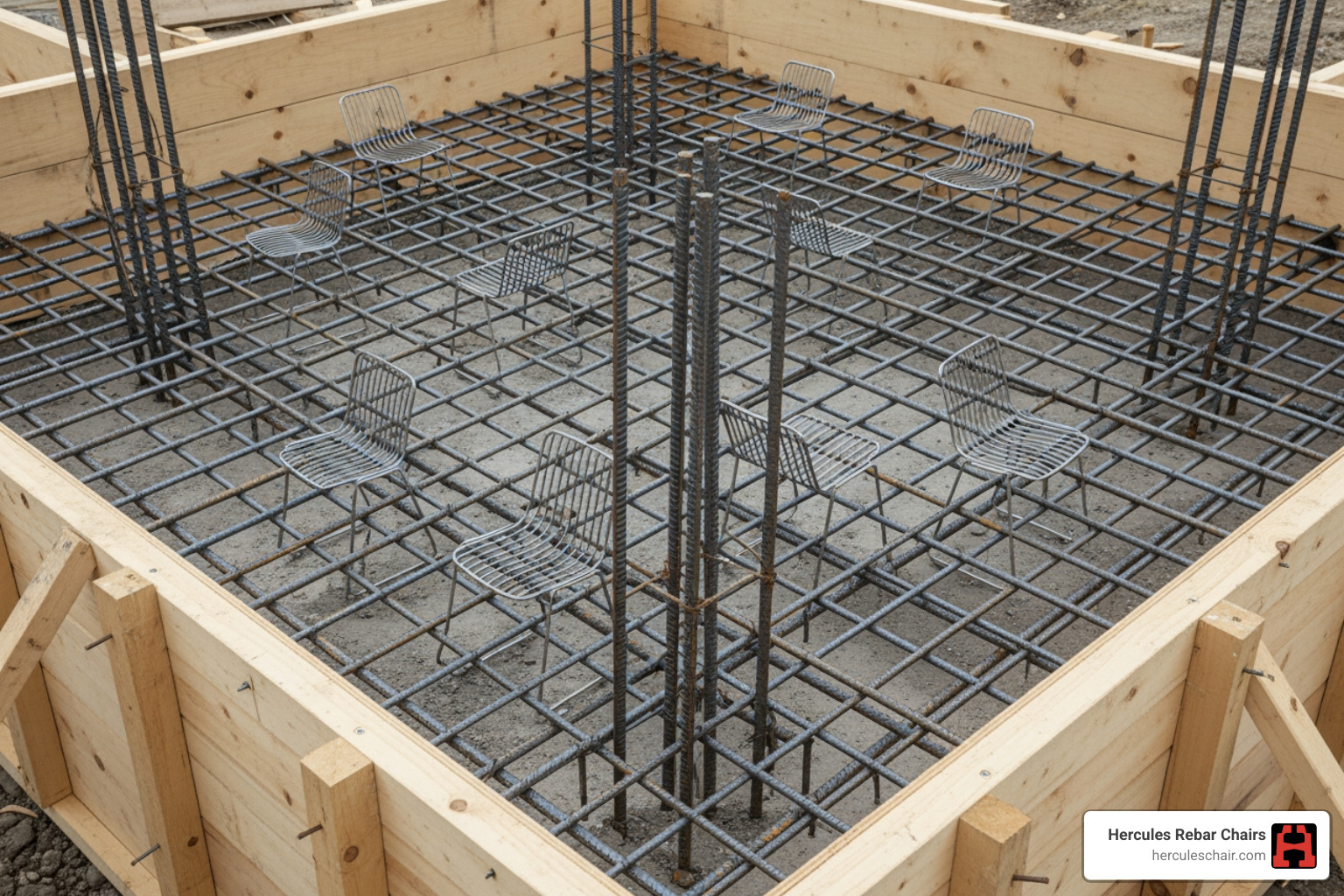

Securing the Grid: Supports and Tying

Once the rebar grid is laid out with the correct spacing and cover, it needs to be secured to prevent any movement during the concrete pour. This is where our trusty allies, rebar chairs and other supports, become indispensable.

We use rebar chairs and other supports to keep the reinforcing steel at the proper elevation and position. Placing rebar directly on the subgrade or on fresh concrete and then trying to pull it up (a practice sometimes called “hooking”) is a big no-no. It’s often ineffective and can lead to structural failures. That’s why we pride ourselves on manufacturing strong, red rebar chairs—they’re designed to ensure your rebar grid stays exactly where it needs to be. With 14 million units sold, our chairs save time, money, and ensure code compliance.

To further secure the rebar grid, we use tie wire. Its main purpose is to prevent displacement during concrete placement, not to add structural strength. We typically use 16½- or 16-gauge black, soft, annealed wire. While it might seem intuitive to tie every intersection, it’s usually unnecessary. Tying every fourth or fifth intersection is often sufficient, unless we’re dealing with a preassembled mat that needs to be rigid for placement. We always make sure tie wire ends are kept away from the concrete surface to prevent rust stains later on.

For a comprehensive look at our range of solutions designed to keep your rebar perfectly positioned, explore Our Products.

Staying Compliant: Navigating Building Codes and Special Conditions

Building a strong foundation isn’t just about getting the rebar in the right place; it’s also about adhering to the strict guidelines set forth by building codes. These codes are our guardians, ensuring safety and structural integrity for every project.

Understanding Code Requirements (IRC & ACI)

In the United States, we primarily steer concrete foundation rebar requirements through two key documents: the International Residential Code (IRC) and the American Concrete Institute (ACI) standards, particularly ACI 318.

- International Residential Code (IRC): The 2024 International Residential Code (IRC®) provides specific guidelines for one- and two-family dwellings. While home inspectors aren’t code enforcers, understanding these rules helps us ensure homes are built safely. The IRC covers everything from footing depth and width to minimum rebar requirements for residential foundations.

- ACI 318 (Building Code Requirements for Structural Concrete): This is the gold standard for structural concrete design and construction. ACI 318 provides minimum requirements for materials, design, and construction of structural concrete elements, including detailed specifications for reinforcement placement, spacing, and protection. It’s a comprehensive document that engineers and detailers rely on heavily.

It’s crucial to remember that local building officials may have amendments or specific interpretations of these codes, so we always check local regulations in states like Alabama, Alaska, Arizona, and across the US.

The role of engineers and detailers here is paramount. Engineers design the foundation, specifying the rebar size, grade, and placement based on structural calculations. Detailers then translate these engineering drawings into precise placing drawings, indicating the number of bars, lengths, bends, and positions. Their meticulous work is then executed by the construction team, with an eye towards proper placement, as detailed in guides like Placing Reinforcing Steel.

Rebar in Seismic Zones

If we’re building in earthquake-prone regions, our approach to concrete foundation rebar reinforcement becomes even more critical. Areas categorized as Seismic Design Categories D0, D1, and D2 require special attention to structural details because, as some say, “your coffee might jump out of the cup all on its own” during a seismic event!

For these zones, the IRC specifies increased reinforcement to help foundations resist the intense lateral, uplift, and shear forces generated by earthquakes. According to IRC Section R403.1.3, concrete footings in these categories must include:

- Vertical Reinforcement: A minimum of one No. 4 bar (1/2 inch diameter) at maximum 48-inch intervals.

- Horizontal Reinforcement: One No. 4 bar within 12 inches of the stem wall’s top and another placed 3-4 inches from the bottom of the footing.

For monolithic slabs with turned-down footings in seismic zones, the IRC requires either one No. 4 bar at both the top and bottom of the footing, OR one No. 5 bar or two No. 4 bars in the middle third of the footing depth.

Beyond the rebar itself, anchor bolts play a critical role in connecting the structure to the foundation. In seismic zones, these must be embedded at least 7 inches into the concrete and typically spaced a maximum of 6 feet apart, though this spacing may be reduced to 4 feet or less in higher risk areas. These anchor bolts, along with proper rebar, prevent the structure from shifting off its foundation during an earthquake, a lesson learned tragically from events like the 1994 Northridge earthquake.

It’s a complex dance of engineering and construction, all aimed at protecting lives and property. We encourage homeowners and builders alike to join the discussion on footing and stem wall reinforcement requirements to better understand these vital safeguards.

Frequently Asked Questions about Foundation Rebar

We often get asked about the practical implications of rebar in foundations. Here are some common questions and our expert answers.

What happens if rebar is placed incorrectly?

Incorrect placement of concrete foundation rebar is like building a house on a foundation of sand—it looks fine until the storm hits. If rebar is too close to the surface, it’s vulnerable to corrosion from moisture, leading to rust, expansion, and eventually cracking and spalling of the concrete. This not only looks bad but severely compromises the foundation’s integrity. If it’s too close to the bottom, it can’t effectively provide tensile strength where it’s needed most to resist bending forces from upward pressure or differential settlement.

The consequences are not just theoretical. Research shows that lowering top bars or raising bottom bars by just 1/2 inch in a 6-inch slab can reduce its load-carrying capacity by a staggering 20%. This seemingly small error can lead to premature cracking, reduced lifespan, and even catastrophic structural failure, requiring costly repairs or complete replacement.

Can rebar be too close together?

Yes, absolutely! While proper spacing is crucial, placing rebar too closely can also weaken the foundation. The problem arises during the concrete pour. When rebar is too dense, it prevents the larger aggregate (stones) in the concrete mix from flowing freely around the bars. This creates voids or “honeycombing” within the concrete, where the aggregate is missing, and only cement paste and sand are present. These voids significantly reduce the concrete’s compressive strength and its ability to bond effectively with the rebar. The result is a weaker composite material that is more prone to cracking and failure, compromising the structural integrity of the entire foundation.

Do I need rebar for a small patio slab?

For a small, simple patio slab that isn’t expected to bear significant weight and is placed on a well-compacted, stable subgrade, you might consider minimal reinforcement or even none, relying instead on proper control joints to manage cracking. However, we generally recommend some form of reinforcement as inexpensive insurance. For such light-duty applications, smaller rebar, like #3 bars, placed at wider spacing (e.g., 12 inches O.C.), can help control shrinkage cracks and provide a little extra resilience. If the patio will support heavy items like a hot tub, an outdoor kitchen, or is on questionable soil, then using rebar is highly advisable to prevent cracking, settlement, and ensure longevity. It’s always better to over-reinforce slightly than to under-reinforce and face costly repairs later.

Conclusion: Building a Foundation That Lasts a Lifetime

Mastering the art and science of concrete foundation rebar placement is paramount to building structures that stand the test of time. We’ve explored the critical role rebar plays in providing tensile strength to otherwise brittle concrete, changing it into a robust, resilient foundation.

From understanding the different types and sizes of rebar to carefully adhering to spacing guidelines and concrete cover requirements, every step in the process contributes to the overall structural integrity and longevity of your foundation. It’s a detailed endeavor that demands precision, knowledge, and the right tools.

Staying compliant with building codes like the IRC and ACI standards, especially in seismic zones, isn’t just a legal obligation; it’s a commitment to safety and durability. The consequences of improper placement—from reduced load-carrying capacity to premature corrosion—are too significant to overlook.

A strong foundation begins with proper planning, correct rebar placement, and adequate cover. This attention to detail ensures that your investment is protected for decades to come. Using quality supports like Hercules Rebar Chairs ensures your rebar grid is perfectly positioned for maximum strength and durability, preventing costly errors and ensuring your foundation is truly built to last. For help selecting the right supports for your project, Buy Rebar Chairs.