Why Bar Chairs Are the Foundation of Quality Concrete Work

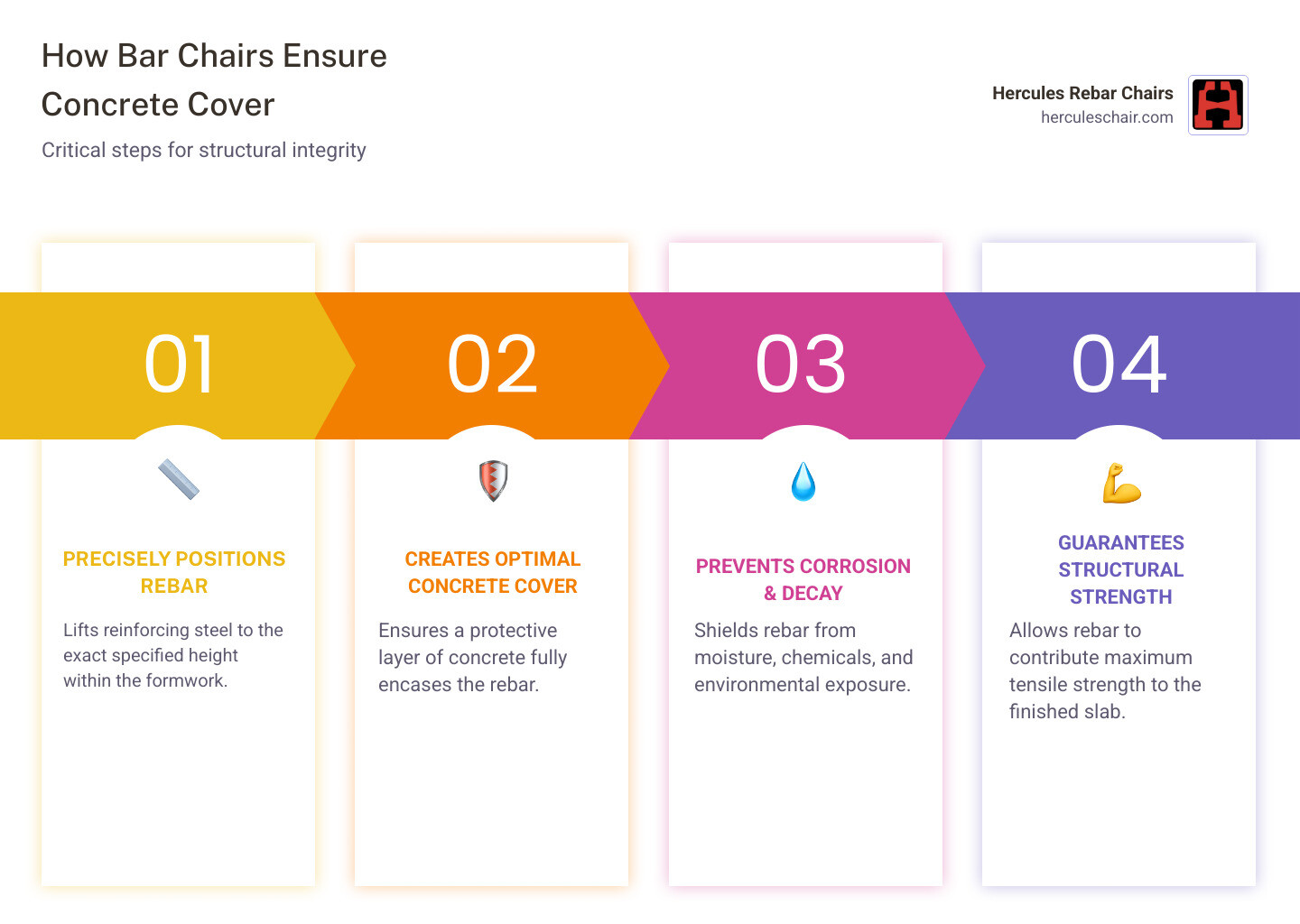

Bar chairs for concrete are small supports that hold reinforcing steel (rebar) at the correct height within concrete forms. This simple function is critical: it ensures proper concrete cover over the rebar, which protects the steel from corrosion and gives the finished slab its structural strength.

Quick Facts About Bar Chairs:

- Primary Function: Keep rebar positioned at a specified height to maintain proper concrete cover.

- Common Materials: Plastic (non-corrosive), Metal (high-strength), Concrete (maximum stability).

- Typical Heights: Range from 3/4″ to 5-3/4″ (20mm to 400mm), depending on slab specifications.

- Key Benefit: Prevent rebar from sinking during the pour, which would expose it to moisture and corrosion.

Without bar chairs, rebar can sink or shift during a concrete pour. This leads to exposed steel, rust, cracking, and structural failures that can cost thousands to repair. Bar chairs solve this by lifting the rebar to the exact specified position, ensuring the slab’s longevity.

Modern bar chairs also save time and money. For example, the Hercules Rebar Footer 2-Bar Chair features a snap-in design that eliminates wire tying. The rebar clicks into place and stays put, even under the weight of flowing concrete.

What Are Concrete Bar Chairs and Why Are They Crucial?

While the quality of the concrete mix and rebar are important, a small, often overlooked component is just as critical: the bar chair for concrete. These devices are the unsung heroes that ensure the structural integrity and longevity of reinforced concrete.

Supporting the Steel and Ensuring Proper Cover

The primary function of a bar chair is to support the rebar and reinforcing mesh at the exact height specified in the project plans. Without this support, the steel would sag under its own weight or be pushed down during the pour, ending up too close to the bottom.

This leads to a lack of “concrete cover”—the protective layer of concrete between the rebar and the exterior surface. Adequate concrete cover is vital for several reasons:

- Corrosion Protection: Steel rebar rusts when exposed to moisture and air. Concrete provides a naturally protective alkaline environment, but only if the rebar is fully encased. If it’s too close to the surface, moisture can seep in, causing the rebar to rust and expand. This expansion cracks the concrete, a process known as spalling, which severely compromises the structure. Bar chairs lift the rebar to create a sufficient moisture barrier.

- Fire Resistance: The concrete cover acts as an insulator, protecting the steel from the high temperatures of a fire that would otherwise weaken it and risk structural collapse.

- Meeting Structural Specifications: Engineering designs dictate a minimum concrete cover to ensure the structure performs as intended. Bar chairs are made in various heights to meet these precise requirements.

Ensuring Durability and Longevity

By holding rebar in the correct position, bar chairs directly contribute to the durability of concrete structures. They prevent the corrosion that leads to cracks and spalling, and they ensure the rebar is properly bonded within the concrete to provide its full tensile strength. Investing in quality bar chairs is a small upfront cost that prevents catastrophic failures and saves significantly on long-term repairs. They are a fundamental component for creating concrete that is strong, resilient, and built to last. For more detailed guidance, check out our Rebar Placement Guide.

Types and Materials: Choosing the Right Bar Chair

Choosing the right bar chair for concrete depends on your project’s specific demands, from load capacity to environmental factors. Different materials offer distinct advantages. You can explore our full range of options on our Our Products page.

Plastic Bar Chairs

Plastic bar chairs are popular for their durability and versatility.

Pros:

- Non-corrosive: Plastic won’t rust, eliminating the risk of stains or corrosion.

- Lightweight: Easy to transport, handle, and install.

- Cost-effective: An economical option for large projects.

- Versatile Designs: Available in many shapes to suit different rebar configurations. Our Hercules Precast X Series Chairs, for example, are made from durable plastic and have a 1000 lb. capacity.

- Recycled Materials: Many modern plastic chairs are made with recycled materials, offering a more sustainable option.

Cons:

- Load Capacity: While some are very strong (like our 1000 lb. X Series), the heaviest rebar cages may require metal alternatives.

- Temperature Sensitivity: Extreme temperatures can affect some plastics, though high-quality chairs are engineered to resist this.

Plastic chairs are ideal for slabs-on-ground and footers, and many feature snap-in designs like the Hercules Rebar Footer 2-Bar Chair, which eliminates the need for wire tying.

Metal Bar Chairs

Metal bar chairs are the workhorses for heavy-duty applications requiring superior strength.

Pros:

- High Strength: Can withstand substantial loads from heavy rebar and thick slabs.

- Rigidity: Ensures rebar remains precisely in place during the pour.

- Applications: Commonly used in suspended slabs and other demanding situations.

Cons:

- Corrosion Risk: Unprotected metal can rust. To prevent this, many metal chairs are plastic-tipped or coated.

- Weight: Heavier than plastic chairs.

- Compliance: Ensure any metal chair used meets all local US building codes and project specifications. Some may be designed to meet other standards, such as AS/NZS 2425:2015.

Concrete Bar Chairs (Dobies)

Concrete bar chairs, or “dobies,” are blocks of concrete with embedded wires for holding rebar.

Pros:

- Maximum Stability: Their weight provides exceptional stability during pours.

- Chemical Bonding: Made of concrete, they bond seamlessly with the poured concrete.

- High Compressive Strength: Can withstand immense pressure.

Cons:

- Heavy: Significantly heavier and more difficult to handle than plastic or metal.

- Brittle: Can crack if dropped before being encased in concrete.

- Labor-Intensive: Can be more time-consuming to place than snap-on plastic chairs.

Concrete chairs are often specified for massive structural elements or in highly corrosive environments.

| Feature | Plastic Bar Chairs | Metal Bar Chairs | Concrete Bar Chairs (Dobies) |

|---|---|---|---|

| Load Capacity | Moderate to High (e.g., Hercules X Series: 1000 lb.) | High (Excellent for heavy rebar) | Very High (Exceptional stability) |

| Cost | Most Cost-effective | Moderate | Higher |

| Corrosion Risk | None (Non-corrosive) | Low (if plastic-tipped/coated) to Moderate (if exposed) | None (Bonds with concrete) |

| Best Use Case | Slabs-on-ground, Footers, Precast, General purpose | Suspended slabs, Heavy rebar, Thick concrete | Massive structures, Corrosive environments, High stability needs |

Selecting and Using Bar Chairs for Concrete Projects

Selecting and correctly using bar chairs for concrete is a pivotal step that directly impacts your project’s structural integrity. It’s about making informed choices and adhering to best practices. Our Hercules Rebar Chair Estimator can help you plan effectively.

Key Features to Look For

When choosing bar chairs, consider these critical features:

- Height Selection: This is paramount. The chair’s height determines the concrete cover. We offer chairs in a wide range of heights, from 3/4″ up to 5-3/4″, to meet design specifications.

- Load Capacity: The chair must support the rebar’s weight plus incidental loads from workers or flowing concrete. Our Hercules X Series Chairs, for example, boast a 1000 lb. capacity. A chair that collapses is a failed chair.

- Base Design: A stable base prevents the chair from sinking or tipping. For projects with vapor barriers, choose chairs with wide, flat bases or use a dedicated Vapor Barrier Mat to prevent punctures.

- Material: As discussed, choose plastic, metal, or concrete based on the environment, required strength, and budget.

Typical Applications and Uses

Bar chairs are indispensable across a broad spectrum of projects:

- Foundations and Footers: They support rebar in the structural base of buildings. Our Hercules Rebar Footer 2-Bar Chair and 2-Bar Footer Stand are designed for these elements.

- Slabs-on-Ground: Chairs lift mesh or rebar off the sub-base to provide the necessary cover.

- Suspended Slabs: For upper floors or bridge decks, chairs are critical for holding complex rebar cages in place over a void.

- Tilt-Up Construction: Specialized chairs are used to ensure precise rebar placement in wall panels that are cast horizontally and tilted into place.

- Precast Elements: In off-site manufacturing, chairs maintain rebar position during casting. Our Hercules Precast X Series Chairs are ideal for these applications.

Common Mistakes to Avoid When Using Bar Chairs

Even the right chairs can be ineffective if used improperly. Avoid these common pitfalls:

- Incorrect Spacing: Placing chairs too far apart allows rebar to sag. Use our Hercules Rebar Chair Estimator to determine optimal spacing.

- Wrong Height: Using a chair that is too tall or short results in incorrect concrete cover. Always double-check project specifications.

- Insufficient Load Capacity: Using chairs that aren’t strong enough will cause them to collapse during the pour.

- Unstable Placement: Place chairs on a firm, level surface to prevent tipping or sinking.

- Chair Collapse During Pour: The dynamic forces of a pour can dislodge flimsy chairs. Invest in high-quality, sturdy chairs, like ours, to prevent this.

The Business Case: Cost, Compliance, and Sustainability

Beyond the structural benefits, bar chairs for concrete have a significant impact on a project’s economics, regulatory compliance, and environmental footprint. Investing in quality rebar support is smart business. You can find more helpful information on our Resources page.

Cost Implications

When evaluating cost, look beyond the price per unit to the overall return on investment.

- Material vs. Labor Costs: While material costs vary, the real savings come from reduced labor. Well-designed products like our Hercules rebar chairs feature a snap-in design that eliminates the need for time-consuming wire tying. This efficiency translates directly into lower project expenses and faster completion times.

- Long-Term Repair Savings: The most significant savings come from preventing future problems. A structure with correctly placed rebar will last longer and require fewer repairs. The cost of fixing corrosion-induced damage far outweighs the initial investment in quality bar chairs.

Industry Standards and Code Compliance

Building codes are mandates designed to ensure public safety. Bar chairs are crucial for meeting these requirements.

- Passing Inspections: Codes specify minimum concrete cover for different elements. Using chairs of the correct height and spacing ensures your project meets these specifications, avoiding costly delays and rework.

- Structural Safety: Compliance equals safety. When rebar is correctly positioned, the concrete element can perform as designed, resisting loads and stresses throughout its service life. Our Hercules rebar chairs are designed to help you meet the demanding specifications of your local US codes.

Sustainability Aspects

In modern construction, sustainability is a key consideration. Bar chairs contribute in several ways:

- Recycled Materials: Many plastic bar chairs are now produced from recycled materials, reducing the demand for virgin plastics and diverting waste from landfills.

- Durability as Sustainability: By ensuring the longevity of concrete structures, bar chairs reduce the need for resource-intensive repairs or replacements. A structure that lasts for decades is inherently sustainable.

- Reducing Waste: Proper rebar placement minimizes the chance of having to demolish and rebuild sections of concrete due to structural deficiencies, which in turn reduces construction waste.

Frequently Asked Questions about Bar Chairs for Concrete

We get a lot of questions about bar chairs for concrete. Here are some of the most common ones, with our expert answers.

How many rebar chairs do I need for my project?

The exact number depends on your project, but here are some solid guidelines:

- Spacing: A general rule is to place chairs every 2 to 4 feet in both directions for mesh or light rebar. For heavier rebar, closer spacing of 1 to 2 feet may be needed to prevent sagging.

- Check Your Plans: The most accurate method is to consult your project’s engineering drawings, which will specify the required chair type and spacing.

- Use an Estimator: To simplify planning, we developed the Hercules Rebar Chair Estimator. This tool helps you accurately calculate the quantity of chairs needed for your project dimensions.

It’s always better to have slightly more support than not enough.

Can I reuse rebar chairs?

In professional construction, the answer is no. Bar chairs are designed for single use.

Once embedded in concrete, they become an integral part of the structure. Attempting to remove them would damage the concrete and compromise the rebar’s position. Furthermore, an extracted chair would likely be damaged and unreliable for a new pour. For guaranteed stability and performance, always use new, undamaged bar chairs that meet your project’s specifications.

What happens if I don’t use bar chairs?

Not using bar chairs for concrete is a critical mistake with severe consequences. Without support, rebar will sink to the bottom of the formwork during the pour.

This results in a lack of concrete cover, leaving the steel exposed to moisture and oxygen. The rebar will inevitably rust. As it rusts, it expands, exerting immense pressure that cracks and spalls the concrete. This destructive cycle compromises the rebar’s ability to provide tensile strength.

In the worst-case scenario, this can lead to structural failure, posing significant safety risks and incurring enormous repair or replacement costs. Using bar chairs is a small, simple step that prevents these catastrophic outcomes.

Conclusion

We’ve seen that bar chairs for concrete are far more than minor accessories; they are essential for the strength, durability, and longevity of any reinforced concrete structure.

By ensuring adequate concrete cover, bar chairs protect rebar from corrosion, improve fire resistance, and allow the structure to achieve its full design strength. This prevents cracking, spalling, and costly premature failures.

At Hercules Rebar Chairs, we are proud to manufacture strong, reliable concrete supports for the construction industry across the USA. Our products are designed to save you time and money, simplify rebar placement, and ensure you meet code compliance.

Choosing the right bar chairs is an investment in your build’s structural integrity and long-term performance. Don’t compromise on this critical component.

Ready to secure your next concrete project? Explore our range and Buy Rebar Chairs from Hercules Rebar Chairs today.