Why Understanding Types of Rebar Couplers Matters for Modern Construction

Types of rebar couplers are mechanical devices that connect reinforcing bars in concrete construction, offering a stronger and more efficient alternative to traditional lap splices. The main categories include:

- Threaded Couplers – Tapered thread and parallel thread systems that require bar end preparation

- Shear-Bolt (Bolted) Couplers – Set screw systems requiring no bar end preparation

- Grouted Sleeve Couplers – Grout-filled sleeves commonly used in precast concrete

- Cold Swaged Couplers – Hydraulically pressed sleeves that deform around the bar

- Specialized Couplers – Weldable, cryogenic, and other application-specific designs

If you’ve ever struggled with congested rebar cages where lap splices create a tangled mess, you know the frustration. Traditional lap splicing consumes extra material, requires complex calculations, and can make concrete placement a nightmare in heavily reinforced sections.

Mechanical rebar couplers solve these problems by transmitting load directly from one bar to another without relying on concrete bond. They’re not just a convenience—they’re often a necessity for large diameter bars, seismic applications, and projects where space is at a premium.

The construction industry has acceptd mechanical splicing because couplers deliver typically 125% greater capacity than lap splices, reduce material waste, and simplify design calculations. Building codes like ACI 318 now recognize mechanical splices as a superior connection method when properly specified and installed.

Whether you’re working on a high-rise column with #10 bars or a seismic zone project requiring ductile connections, understanding which coupler type fits your specific needs can save time, money, and headaches on site.

The Case for Mechanical Splicing: Couplers vs. Lap Splices

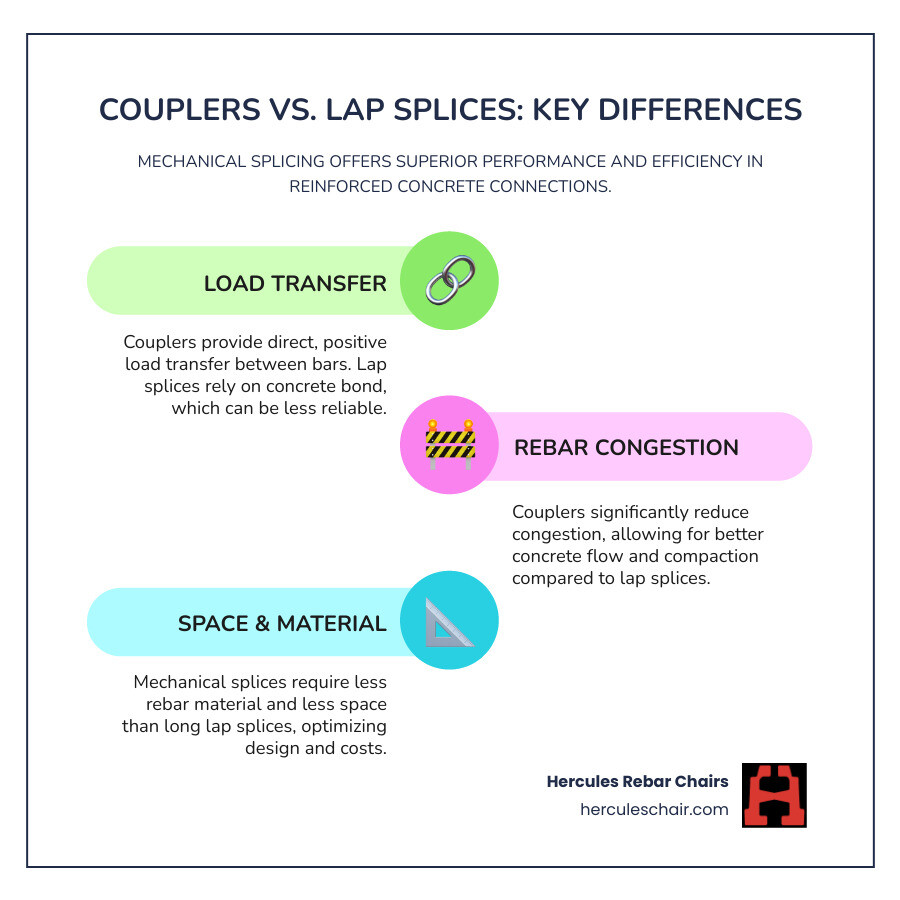

When we talk about connecting rebar, the traditional method has long been the lap splice, where two bars overlap and transfer stress through the surrounding concrete. However, this method has its limitations, especially in modern construction with larger rebar sizes, complex designs, and stringent performance requirements. This is where mechanical rebar couplers shine, offering a robust and often superior alternative.

Primary Advantages of Rebar Couplers

The shift towards mechanical couplers isn’t just a trend; it’s driven by tangible benefits that improve structural integrity, efficiency, and safety on our construction sites across the USA.

One of the most significant advantages is the direct load transfer. Unlike lap splices that rely on the bond between rebar and concrete, mechanical couplers transmit the rebar load directly from one bar to another. This means the connection doesn’t depend on the concrete’s strength or condition, leading to more reliable and predictable structural performance.

This direct load transfer mechanism also contributes to improved seismic performance. During an earthquake, concrete surrounding lap splices can crack, leading to bond failure. Couplers, especially those designed for seismic applications, maintain the continuity of the rebar, ensuring the structure can withstand dynamic forces. They offer improved structural integrity, particularly during seismic events, by not relying on concrete for load transfer.

Another huge benefit is the reduced rebar congestion. If you’ve ever tried to pour concrete into a dense forest of lapped rebar, you know the struggle. Lap splices can create bottlenecks, making it difficult to place and compact concrete effectively. Couplers, being more compact, significantly reduce congestion, allowing for better concrete flow and compaction, which in turn leads to a stronger, more durable concrete element. This also helps in creating smaller columns with larger diameter rebar.

We also see considerable material savings. Traditional lap splices require a significant overlap, meaning we use more rebar than structurally necessary. This extra material translates directly to higher costs. Couplers eliminate this waste, leading to a reduction in steel consumption. For instance, building codes often require up to 50% longer splice laps for epoxy-coated bars compared to standard rebars, making couplers even more attractive for these specialized applications.

Beyond material, couplers offer simplified design. They eliminate the need for complex lap-splice calculations, which can be time-consuming and prone to error. This streamlines the design process and reduces hidden costs associated with preparing lap splices and additional transverse reinforcement.

Finally, improved site safety is a critical, often overlooked, advantage. Protruding rebar from lap splices can pose a significant hazard on a busy construction site. Couplers, with their compact and contained nature, eliminate these dangerous protrusions, making the work environment safer for everyone. Plus, mechanical splices deliver higher performance than lap splices, typically offering 125% greater capacity, a testament to their strength and reliability.

Cost and Material Considerations

While the upfront cost of a rebar coupler might seem higher than simply overlapping two bars, a closer look at the overall project economics often reveals a different story.

Lap splice costs accrue not just from the extra rebar length required for the overlap, but also from the increased labor to tie these longer sections, the potential for re-work due to poor concrete consolidation in congested areas, and the need for additional transverse reinforcement to prevent splitting. When considering expensive epoxy-coated bars, the requirement for significantly longer lap lengths further inflates costs.

In contrast, while the initial purchase price of couplers might be higher, they lead to significant material savings by eliminating the need for excessive rebar overlap. This reduction in steel can offset the coupler cost, especially for larger diameter bars.

Research from as far back as 1998 found that the additional cost of using mechanical butt splices was about 0.2 percent of the total cost of the structure. This suggests that the impact on overall project budget is minimal, especially when considering the numerous benefits. The cost-effectiveness with large rebar is particularly pronounced: the cost advantage of using a coupler instead of lapping may increase with rebar size, ranging from approximately 11% for #5 bars to 140% for #10 bars. This is because larger bars require proportionally longer lap lengths, making couplers relatively more economical. The overall minimal total project cost impact makes them a compelling choice.

Couplers also optimize installation labor. While lap splices require careful measurement and tying, many couplers are designed for quick and easy assembly, sometimes without specialized tools, saving valuable time on site.

Potential Limitations and Disadvantages

No solution is without its trade-offs, and rebar couplers are no exception. While their advantages are compelling, we must also acknowledge their potential limitations.

One of the most immediate considerations is the initial material cost. As we discussed, while often offset by other savings, the unit cost of a coupler can be higher than the equivalent length of rebar for a lap splice. This upfront expense needs to be factored into budgeting.

Another critical aspect is the required technical knowledge and supervision needs. Installing couplers correctly isn’t always as intuitive as tying rebar. Many systems require specific procedures, torque settings, or special tools. This demands that our teams are properly trained and that there is high attention and proper supervision during installation to ensure the connection performs as designed.

Closely related to this is the importance of quality control. Poorly installed or incompatible coupler joints can lead to structural failures, undermining the very purpose of using them. This is why rigorous adherence to manufacturer guidelines and project specifications is paramount.

Finally, we need to consider concrete cover considerations. Mechanical couplers are inherently bulkier than a single rebar. When using mechanical splices, we must provide cover similar to that specified for reinforcement, and sometimes even more, due to the larger coupler size. This can occasionally impact architectural finishes or require slight adjustments to formwork.

An In-Depth Look at the Different Types of Rebar Couplers

The world of rebar couplers is diverse, with various types designed to meet specific project demands and installation conditions. Understanding these types of rebar couplers is key to making the right choice for your build.

Threaded Couplers: The Industry Standard

Threaded couplers are arguably the most common and versatile types of rebar couplers we encounter. They fundamentally consist of an annular sleeve with internal threads designed to engage with external threads on the rebar ends.

The installation process typically involves preparing the bar ends by threading them. One bar is then screwed into one end of the coupler, and the other bar is screwed into the opposite end, usually until a predetermined torque is reached or the bars meet in the middle.

Common applications for threaded couplers include:

- Connecting vertical rebar in columns and walls.

- Splicing rebar in beams and slabs.

- Creating continuity in precast concrete elements.

- Extending existing rebar in renovation or expansion projects.

- Anywhere a full-strength, positive connection is required.

Tapered Thread Couplers

Tapered thread couplers are engineered for efficiency. They feature a pronounced taper angle on their threads, which allows for extremely fast installation with minimal turning of the rebar or coupler. This design makes them particularly robust and less susceptible to cross-threading, saving significant time on site. Think of it like a quick-release mechanism for your rebar connections.

Parallel (Straight) Thread Couplers

In contrast, parallel (straight) thread couplers use threads that run straight along the bar. These often require the rebar to have an upset thread diameter, meaning the end of the bar is expanded before threading, ensuring the thread pitch is larger than the rebar’s normal diameter for optimal strength. Alternatively, some systems cut threads directly onto the rebar.

A major advantage of straight threaded couplers is their compliance with UNC bolt thread specifications, which allows for greater interoperability between rebar and couplers from different manufacturers. However, they typically involve a longer installation process compared to tapered threads, as more rotations are required to achieve a full engagement.

Shear-Bolt / Bolted Couplers

For situations where bar end preparation like threading isn’t feasible or desired, shear-bolt or bolted couplers offer an excellent solution. These are often referred to as set screw type couplers.

The beauty of these types of rebar couplers is that they require no bar end preparation. The coupler consists of a sleeve with a series of special shear-head bolts or set screws. During installation, the rebar ends are inserted into the coupler, and the bolts are tightened. Each bolt is designed to shear off at a predetermined torque, ensuring the correct clamping force is applied to the rebar.

This system allows for simple visual inspection: once the heads of the bolts have sheared off, you know the connection is properly made. This makes them ideal for repairs or situations where quick, straightforward installation is paramount.

Other Specialized types of rebar couplers

Beyond the mainstream threaded and bolted options, we have specialized types of rebar couplers designed for unique applications.

Grouted sleeve couplers are commonly used in precast concrete construction. These couplers consist of a steel sleeve into which the rebar ends are inserted. The void between the rebar and the sleeve is then filled with a high-strength, non-shrink grout, which cures to create a robust connection. They are excellent for connecting precast elements on-site.

Cold swaged couplers involve a process where a steel sleeve is hydraulically pressed onto the rebar ends. A powerful hydraulic press deforms the sleeve around the bar, creating a mechanical interlock. This method creates a very strong, full-capacity connection without heat or threading.

For situations requiring connections to structural steel elements, weldable couplers are invaluable. These couplers are designed to be welded directly to steel plates or sections, providing a secure anchorage for the rebar. This is particularly useful in complex connections where rebar needs to tie into steel frameworks.

And for the most extreme environments, we have cryogenic couplers. These specialized couplers are engineered to maintain their performance and integrity at extremely low temperatures. For instance, some tapered thread cryogenic couplers are tested at -168°C (-270°F), making them essential for applications like LNG facilities or other structures in ultra-cold conditions.

Key Applications and Scenarios for Rebar Couplers

Understanding the different types of rebar couplers is one thing, but knowing when and where to use them is where the real expertise lies. Couplers are not just an alternative; they are often the preferred or even necessary solution in specific construction scenarios across the USA.

High-Congestion Reinforcement Areas

Imagine a column, a beam-column joint, or a raft foundation designed for heavy loads. These areas often require a dense network of rebar. If we were to rely solely on lap splices here, we’d quickly end up with a tangled mess, a “rebar jungle” that makes concrete placement a nightmare.

This is precisely where mechanical couplers become indispensable. By using compact couplers instead of lengthy overlaps, we can drastically reduce rebar congestion. This leads to improved concrete flow during pouring, ensuring the concrete reaches every corner and encapsulates the rebar properly. The result is better compaction, fewer voids, and ultimately, a stronger, more durable concrete element.

For these critical areas, ensuring proper rebar placement is paramount. That’s why high-quality rebar chairs and supports, like those we offer, are essential to maintain the design integrity of your reinforcement cage. Explore our comprehensive range of rebar support solutions to ensure your rebar stays exactly where it needs to be, even in the most congested sections. Our Products

Splicing Large Diameter Bars

When we’re working with large diameter rebar, such as bars greater than #11 (or greater than 32mm, as often referenced in other international standards), the impracticality of lapping becomes glaringly obvious. The required lap lengths for these bars can be excessively long, making them unwieldy, difficult to manage on site, and highly inefficient in terms of material use and space.

In these situations, mechanical couplers provide a straightforward and efficient way to achieve a full-strength connection. They ensure the entire load-carrying capacity of the large bar is transferred, which is critical for the structural integrity of heavy-duty elements like those found in bridge piers or large foundations.

Seismic and Dynamic Loading Applications

For structures in seismic zones or those subjected to significant dynamic loading, the performance of rebar connections is paramount. The ability of the rebar to exhibit ductility – to deform without fracturing – is crucial for a structure to safely absorb seismic energy.

This is where “bar break” performance comes into play. A coupler with “bar break” performance ensures that the ultimate tensile strength of the rebar is exceeded by the coupler itself. This means that if failure occurs, it will happen in the rebar away from the coupler, allowing the rebar to achieve its full ductility. This is a critical feature for maintaining structural integrity during an earthquake.

In these demanding applications, Type 2 couplers are the heroes. The ACI 318 code specifies that Type 2 couplers are designed to develop the specified tensile strength of the spliced bars and are intended for yielding regions where the rebar is expected to undergo significant inelastic deformation. This ensures a reliable load path throughout the structure, even under extreme seismic events.

Understanding Rebar Coupler Standards and Performance

To ensure the safety and reliability of our structures, rebar couplers must adhere to rigorous performance requirements and standards. In the United States, the American Concrete Institute (ACI) is the primary authority. However, understanding global perspectives can provide valuable context on what defines a high-quality coupler.

| Feature / Standard | ACI 318 (USA) | Eurocode 2 (Europe) | BS 8597 (UK) |

|---|---|---|---|

| Strength Req. | Type 1: 125% of yield strength (1.25Abfy) | Full capacity (e.g., characteristic strength of 500 MPa rebar) | Tensile strength based on rebar grade (e.g., 525 MPa for B500A) at 99% char. str. |

| Type 2: Specified tensile strength (1.0 f_u) | |||

| Ductility Req. | Maintain bar ductility, esp. Type 2 for yielding regions | Maintain bar ductility, especially for seismic (e.g., ‘bar break’ systems) | Residual elongation (slip) ≤ 0.10mm or strain < 0.16% |

| Fatigue Classes | Implied by application (e.g., seismic) | Not explicitly categorized in general, but assessed for fatigue performance | Class F, Class D, Class R (for different fatigue loading levels) |

| Large Bar Def. | #11 and larger | > 32mm | No specific definition, but lapping issues with larger bars are acknowledged |

| Seismic Req. | Type 2 in yielding regions; staggering required (30 in / 750mm) | ‘Bar break’ systems crucial; specific detailing for ductile frames | ‘Bar break’ systems for seismic; CARES TA1-C for nuclear |

Performance Classifications: Type 1 vs. Type 2 Couplers

In the US, ACI 318 provides clear distinctions for coupler performance, primarily categorizing them into Type 1 and Type 2.

A Type 1 coupler is a mechanical splice that can develop 125% of the yield strength of the bars in tension or compression. These are suitable for locations where yielding of the reinforcement is not anticipated. Think of areas under normal service loads where the rebar isn’t expected to stretch significantly.

However, for critical applications, especially those subject to seismic forces, we turn to Type 2 couplers. These couplers not only meet the requirements of Type 1 couplers but also can develop the specified tensile strength of the spliced bars. This means they are designed to perform even when the rebar itself is stretching into its plastic range, making them essential for seismic applications and other yielding regions where we need the rebar to maintain its integrity under extreme stress.

International Standards and Certifications

While ACI 318 guides our projects in the USA, it’s worth noting that other regions have their own rigorous standards. For example, Eurocode 2 and BS 8597 from the UK detail specific performance criteria, including tensile strength, residual elongation (slip), and fatigue classes.

These various standards, along with certifications from bodies like CARES (Certification Authority for Reinforcing Steels) in the UK, serve a common purpose: to ensure the quality and reliability of rebar couplers. Such certifications involve extensive testing and auditing of manufacturing processes, giving engineers and contractors confidence in the performance of the products they specify. They help us verify that the couplers we use are robust, durable, and capable of performing as designed.

Code Requirements for Placement and Staggering

The placement of mechanical splices is not arbitrary; it’s governed by strict code requirements to ensure structural integrity. ACI 318 specifies location restrictions, stating that mechanical splices generally should not be located within a distance equal to twice the member depth from the column or beam face for special moment frames or from critical sections where yielding of the reinforcement is likely to occur. An exception is made for Type 2 mechanical splices on Grade 420 reinforcement, which are designed for such demanding conditions.

Furthermore, staggering in seismic zones is a non-negotiable requirement. In special moment frames and special structural walls, the ACI 318 Code mandates that mechanical splices be staggered at least 30 inches (750 mm). This means that adjacent bars should not be spliced at the same location. Why the staggering? It helps to reduce stress concentration, improves concrete placement (as it prevents a dense cluster of couplers), and minimizes the risk of cracking in the concrete around the splice regions. Essentially, staggering distributes the load transfer more effectively, enhancing the overall performance of the structure during an earthquake.

Frequently Asked Questions about Rebar Couplers

We often get asked practical questions about rebar couplers. Here are some common ones that help clarify their use on our construction sites.

Can you mix different types of rebar couplers in a project?

Generally, we do not recommend mixing different types or brands of rebar couplers within the same structural element or even throughout a project without explicit engineering approval. Each coupler system is designed with specific tolerances, materials, and installation procedures. Mixing them can lead to unpredictable performance, compromise the structural integrity, and complicate quality control. It’s always best to follow engineer specifications and adhere to a single, approved system to ensure predictable performance and maintain consistency. If you’re unsure, consult with your structural engineer.

Do rebar couplers require special tools for installation?

The need for special tools largely depends on the type of rebar coupler.

- Threaded couplers often require a torque wrench to ensure proper tightening to the manufacturer’s specified torque value, or a standard wrench for manual turning.

- Shear-bolt couplers are designed so that their bolts shear off at a predetermined torque, making a standard wrench sufficient for installation and providing a visual confirmation.

- Cold swaged couplers require a hydraulic press to deform the sleeve onto the rebar.

- Grouted sleeve couplers require equipment for mixing and injecting the grout.

Always refer to the manufacturer’s installation instructions for the specific coupler you are using to determine the necessary tools.

How do you inspect a rebar coupler connection?

Inspection methods vary by type of coupler:

- For threaded couplers, inspection often involves visual checks to ensure full thread engagement and sometimes torque verification using a torque wrench. Some systems might have visual indicators like exposed threads or alignment marks.

- For shear-bolt couplers, inspection is straightforward: you simply confirm that the heads of all the bolts have sheared off, indicating that the correct clamping force has been applied.

- For grouted sleeve couplers, inspection typically involves procedural checks during installation to ensure proper grout mixing and injection, and sometimes testing of grout samples.

- For swaged couplers, visual inspection confirms the sleeve has been properly deformed, and sometimes dimensional checks are performed.

Regardless of the type, thorough documentation of the installation process and adherence to manufacturer guidelines are crucial for effective quality control.

Conclusion: Building Stronger with the Right Connections

As we’ve explored, mechanical rebar couplers offer compelling advantages over traditional lap splices, providing improved structural integrity, reduced congestion, and improved safety across our construction projects in the USA. From the robust threaded varieties to the no-prep shear-bolt systems and specialized solutions for extreme conditions, the types of rebar couplers available empower us to build smarter and stronger.

Choosing the correct coupler type, understanding its performance characteristics, and ensuring adherence to standards like ACI 318 are critical steps in any successful project. For a solid foundation, every component matters, from the rebar connections to the supports that ensure proper placement. Hercules Rebar Chairs provides robust support solutions, ensuring that your reinforcement remains perfectly positioned, allowing your couplers to perform optimally.

To learn more about high-quality components for your concrete projects, explore our splicer products.