Why Accurate Rebar Estimation Matters for Every Concrete Pour

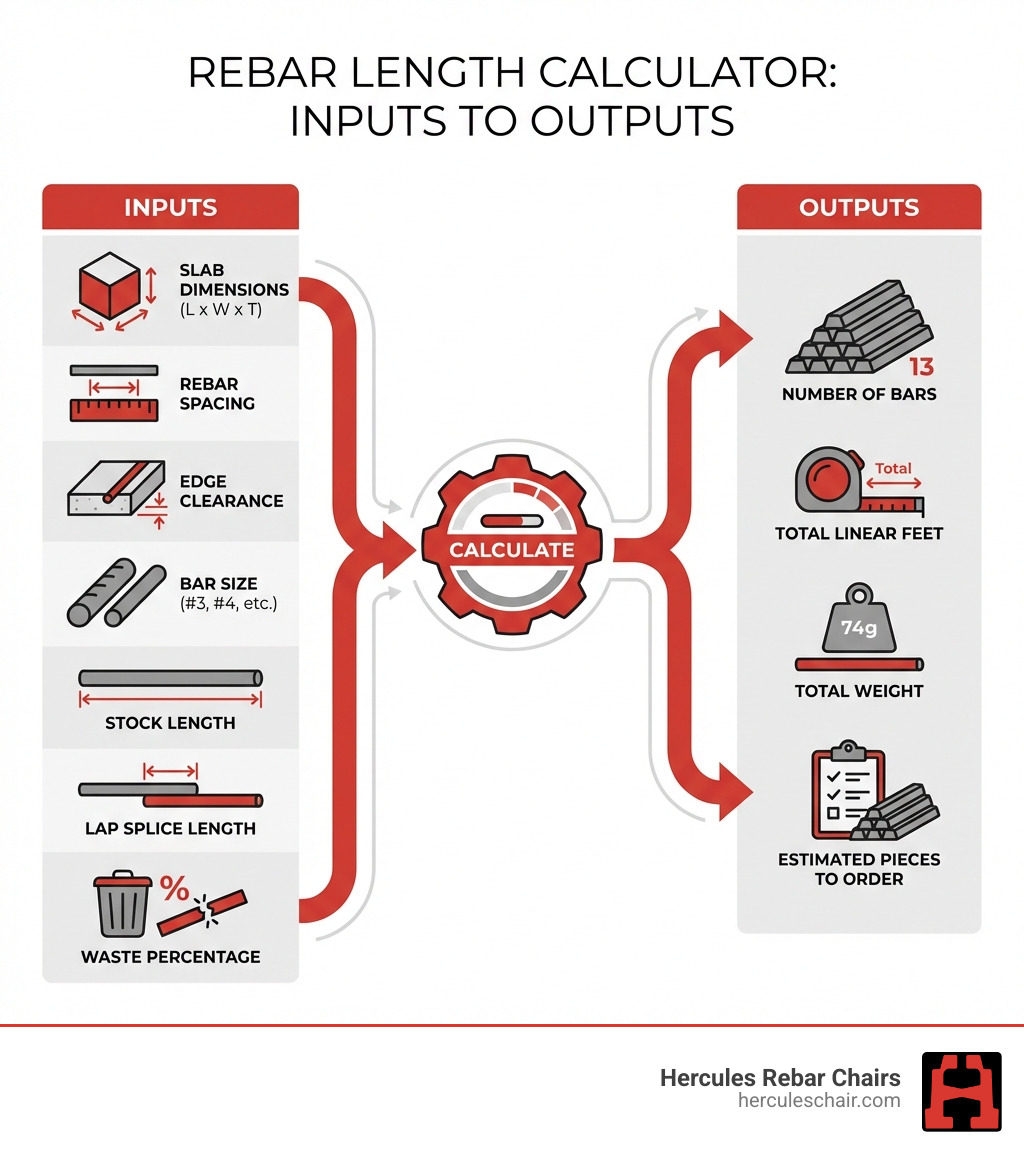

A rebar length calculator helps you determine exactly how much reinforcing steel you need for a concrete project by converting your slab dimensions, spacing requirements, and edge clearances into total linear feet, bar counts, and estimated weight.

Quick answer: To use a rebar length calculator:

- Enter your project dimensions (length, width, thickness)

- Set rebar spacing (typically 18-24 inches on-center)

- Define edge clearance (cover distance from slab edge)

- Input bar size (#3, #4, #5, etc.)

- Add stock length and lap splice requirements

- Apply waste factor (usually 5-10%)

- Review outputs: total bars needed, linear feet, and weight

We’ve all been there. You’re halfway through a critical foundation pour when you realize you’re three bars short. Now you’re scrambling to source materials, delaying the entire job, and watching your budget evaporate with every passing hour.

Running short on rebar isn’t just frustrating—it creates project delays, wasted labor hours, and budget overruns that eat into your profit margins. On the flip side, overordering means you’re tying up cash in materials sitting unused on site.

Getting rebar quantities right matters for concrete reinforcement and structural integrity. Too little steel and you risk code violations or worse. Too much and you’ve wasted money. But manual calculations are time-consuming and error-prone, especially when you’re juggling multiple pours across different jobs.

That’s where accurate estimation tools become essential. Modern rebar calculators take the guesswork out of material takeoffs, helping you order exactly what you need—with the right contingency built in—so you can focus on getting quality pours done on schedule.

What is a Rebar Length Calculator and Why Use One?

A rebar length calculator is a digital tool designed to simplify and automate the complex process of estimating the amount of reinforcing steel needed for concrete construction projects. Instead of tedious manual measurements and calculations, this tool takes your project specifications and quickly provides precise quantities of rebar required. It’s an invaluable asset for contractors, estimators, and even DIY enthusiasts.

The primary purpose of rebar (reinforcing bar) in concrete is to improve its tensile strength. While concrete excels under compression, it is weak when subjected to pulling or stretching forces. Rebar, typically made of steel, provides that much-needed tensile reinforcement, preventing cracking and ensuring the long-term durability and structural integrity of concrete structures. You can learn more about the purpose of rebar in concrete.

This critical role of rebar means that accurate estimation of its quantity isn’t just about saving money, it’s about ensuring safety and compliance with building codes. A rebar length calculator automates the otherwise labor-intensive manual math, significantly reducing the chances of human error.

How a Calculator Helps Estimate Material Needs

At its core, a rebar length calculator works by converting your project’s physical dimensions and rebar layout requirements into quantifiable material needs. You input parameters like the length and width of your concrete slab, the desired spacing between rebar bars, and the necessary edge clearances. The calculator then processes this information to determine the total number of rebar pieces, their individual lengths, and the overall linear footage required.

The key inputs required for a rebar length calculator typically include:

- Project Dimensions: Length, width, and sometimes thickness of the concrete element (e.g., slab, footing, wall).

- Rebar Spacing: The distance between the center points of adjacent rebar bars, both in the length and width directions.

- Edge Clearance (Cover): The distance from the outermost rebar bar to the edge of the concrete.

- Rebar Size: The diameter or gauge of the rebar being used (e.g., #3, #4, #5).

- Stock Bar Length: The standard lengths in which rebar is purchased (e.g., 20 ft, 40 ft, 60 ft).

- Lap Splice Length: The required overlap when two rebar bars need to be joined to achieve a longer continuous length.

- Waste Factor: A percentage added to the total to account for cutting errors, off-cuts, and unforeseen circumstances.

Once these inputs are provided, the calculator performs the necessary computations. For instance, it will calculate how many runs of rebar are needed across the width and length of a slab, then sum these up to give you a theoretical total linear footage. It will also factor in lap splices and, crucially, a waste percentage. The calculator outputs are pure computed totals. If your workflow uses waste or trim, you’ll add it on top of Total Length as a percentage. For simple grids, a 5–8% waste factor is common; complex geometry, heavy splicing, or short stock lengths may justify 10%+ or more.

This automation means:

- Accurate Material Estimation: It converts dimensions into precise quantities, ensuring you order neither too much nor too little.

- Simplified Ordering: By providing total linear feet, number of bars, and estimated weight, it makes the procurement process straightforward.

- Reduced Waste: Minimizing over-ordering directly translates to less material waste and lower disposal costs.

- Improved Logistics: Knowing the total weight helps plan for delivery, handling, and storage on site.

Using Calculator Outputs for Cost Estimation

Beyond simply telling you how much rebar you need, the outputs from a rebar length calculator are fundamental for comprehensive cost estimation in construction projects. This isn’t just about the price of the steel itself; it impacts various other financial aspects:

- Material Takeoff Accuracy: The precise total linear footage and weight directly feed into your material budget. When you know exactly how much rebar (and what sizes) you need, you can get accurate quotes from suppliers.

- Budgeting Accuracy: With reliable material quantities, you can create a more accurate project budget, reducing the risk of unexpected material overruns. This helps in securing financing and managing client expectations.

- Labor Planning: While the calculator focuses on material, knowing the quantity and complexity of rebar installation (e.g., many laps, different bar sizes) helps estimate the labor hours required for cutting, bending, tying, and placing the rebar.

- Weight-Based Shipping Costs: Rebar is heavy. The calculator’s ability to estimate total weight (using standard ASTM weight/ft for each bar size, e.g., #4 is 0.668 lb/ft, #5 is 1.043 lb/ft) is crucial for calculating transportation and delivery costs, especially for large projects.

- Project Bidding: For contractors, accurate cost estimation based on rebar length calculator outputs is vital for competitive bidding. Underestimate, and you risk losing money; overestimate, and you might lose the bid.

By integrating the calculator’s outputs into your project management, you gain a clearer financial picture, enabling better decision-making and more profitable projects.

How to Use a Rebar Length Calculator: A Step-by-Step Guide

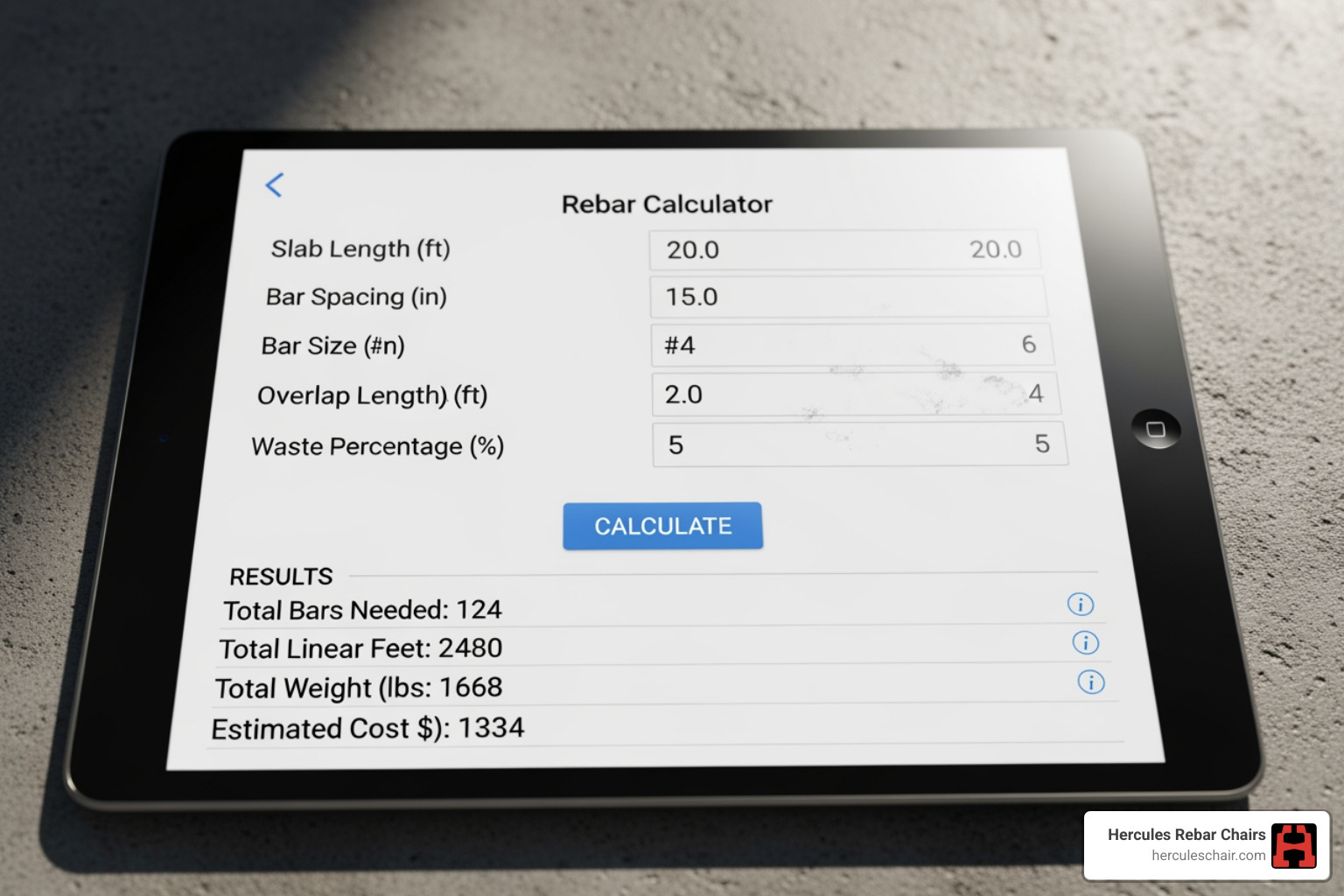

Using a rebar length calculator effectively is a straightforward process that hinges on accurate input data. Let’s walk through the essential steps to ensure you get reliable results for your concrete slabs, foundations, and other reinforced elements.

Step 1: Input Project Dimensions

The first crucial step is to accurately measure and input the dimensions of the concrete element you are reinforcing.

- Slab Length and Width: For a rectangular slab, this is simply the overall length and width of the area to be poured.

- Foundation Area: For foundations or footings, you’ll input the overall dimensions.

- Consistent Units: Always ensure you are using consistent units (e.g., all feet and inches, or all meters). Most calculators allow you to switch between US customary units (feet, inches) and metric units (meters, millimeters).

- Irregular Shapes: If your project involves irregular shapes, you’ll need to break them down into smaller, calculable geometric shapes (like rectangles or squares). Calculate the rebar for each section and sum them up for the total.

For example, if you have a 20 ft by 15 ft slab, these are your primary length and width inputs. This is the foundation upon which all other calculations will be built.

Step 2: Define Rebar Spacing and Edge Clearance

Once your overall dimensions are in, you need to tell the calculator how the rebar will be laid out within that space.

- On-Center Spacing: This refers to the distance from the center of one rebar bar to the center of the next. For flat slabs like driveways and patios, common spacing is roughly 18 to 24 inches on-center. For foundations, building codes often require rebar to be spaced no more than 18 inches apart. For walls, vertical rebar is typically spaced at a minimum of every 36 inches on center, and horizontally every 24 inches minimum. Always consult your project engineer, local building codes, or structural drawings for the exact required spacing.

- Edge Clearance (Cover): Also known as concrete cover, this is the distance from the outermost rebar bar to the finished surface or edge of the concrete. Edge clearance is critically important because it protects the steel from corrosion due to moisture and chemicals, and provides fire resistance. The calculator places the first bar near the cover and continues at your specified spacing until the far edge is satisfied. Changing this cover can subtly change the clear span and potentially add or subtract a bar on each edge.

- For example, if you have a 10 ft x 10 ft slab with a 3-inch clearance on all sides, the actual rebar grid dimensions would be 9 ft 6 inches x 9 ft 6 inches.

- Proper rebar placement is crucial for structural integrity. You can refer to our Rebar Placement Guide for more details on best practices.

Step 3: Factor in Lap Splices and Waste Using a Rebar Length Calculator

This step accounts for the realities of working with rebar—it doesn’t always come in the exact length you need, and mistakes or off-cuts happen.

- Stock Bar Length: Rebar is typically sold in standard lengths such as 20 ft, 30 ft, 40 ft, or 60 ft. You’ll input the stock length you plan to purchase. The calculator will determine how many pieces of this stock length are needed to cover your project’s dimensions. A clever trick: if your stock length is longer than the span of your concrete element in a particular direction, each line in that direction becomes a single piece, eliminating the need for lap splices and reducing total weight.

- Lap Splice Length: When your concrete element is longer than a single stock bar, you’ll need to join two bars together using a lap splice. This involves overlapping the ends of the bars by a specified length to ensure proper stress transfer between them. Typical tension lap splices range from 40d–60d (where ‘d’ is the bar diameter). For example, for a #4 bar (1/2 inch diameter), a 40d lap would be 40 * 0.5 inches = 20 inches. Lap splices add significantly to your total rebar length, and large grids with segmented bars can accumulate substantial lap length – make sure your calculator accounts for this. Always follow your project specifications and local code for lap development. You can find more on rebar standards.

- Waste Percentage (5-10%): Even with perfect planning, some rebar will be wasted due to cutting errors, necessary off-cuts that are too short to use, or unforeseen field adjustments. It’s standard practice to add a waste factor to your calculated total. For simple grids, 5–8% is common; for complex geometry, heavy splicing, or when using short stock lengths, 10% or more might be justified. This buffer helps prevent frustrating shortages and keeps your project on track.

By carefully following these steps, your rebar length calculator will provide a highly accurate estimate, setting you up for a smooth and efficient rebar installation.

Understanding Key Rebar Details for Accurate Calculations

While a rebar length calculator handles the math, understanding the properties and types of rebar is essential for making informed decisions and ensuring the structural integrity of your concrete project.

Rebar Sizing and Types Explained

Rebar comes in various sizes and types, each suited for different applications and structural demands.

- US Sizing System: In the United States, rebar is typically designated by a number (e.g., #3, #4, #5). This number correlates directly to its nominal diameter in eighths of an inch.

- #3 Rebar: 3/8 inch diameter. Commonly used for light residential work, such as patios, sidewalks, and small slabs.

- #4 Rebar: 4/8 inch or 1/2 inch diameter. A versatile size, often used for driveways, garage slabs, walls, and columns.

- #5 Rebar: 5/8 inch diameter. Frequently specified for foundations, footings, and more heavily loaded concrete structures.

- Larger sizes like #6 (3/4 inch) and beyond are typically reserved for industrial, commercial, or heavy civil projects.

| Rebar Size (US #) | Nominal Diameter (inches) | Typical Applications |

|---|---|---|

| #3 | 0.375 (3/8) | Patios, sidewalks, light slabs |

| #4 | 0.500 (1/2) | Driveways, garage slabs, walls, columns |

| #5 | 0.625 (5/8) | Foundations, footings, heavy slabs |

| #6 | 0.750 (3/4) | Commercial, industrial, large foundations |

- Bar Grades: Rebar also comes in different grades, indicating its yield strength (e.g., Grade 40, Grade 60). Grade 60 (420 MPa) is a very common choice for general construction due to its strength. The grade chosen will depend on the structural requirements of your project, as specified by an engineer.

- Types of Steel and Coatings: Most rebar is made from carbon steel, which is cost-effective and strong. However, for projects in corrosive environments (e.g., coastal areas, bridge decks exposed to de-icing salts), specialized types of rebar are used:

- Epoxy-Coated Rebar: Has a protective epoxy coating to resist corrosion. This can sometimes require longer lap splices or development lengths due to reduced bond with concrete, so consult your engineer.

- Galvanized Rebar: Coated with zinc for corrosion resistance.

- Stainless Steel Rebar: Offers superior corrosion resistance but is more expensive.

Always ensure the rebar size and type you input into the rebar length calculator match the specifications in your project’s structural drawings.

The Importance of Lap Splices and Development Length

While we’ve touched on lap splices as a factor in calculating total rebar length, it’s crucial to understand their structural significance, along with the concept of development length.

- Lap Splices: These are the most common way to join two pieces of rebar to achieve a continuous longer length. They work by overlapping the bars, allowing the stress to transfer from one bar to the concrete, and then back into the other bar. The required lap splice length is critical for ensuring the structural continuity of the reinforcement. If the lap is too short, the connection can fail, compromising the entire structure. Lap lengths are typically specified as a multiple of the bar diameter (e.g., 40d, 60d) and are influenced by concrete strength, rebar grade, coating, and the location within the concrete element.

- Development Length: This refers to the minimum length of rebar that must be embedded in concrete to ensure that the bar can develop its full yield strength without pulling out. It’s a critical design consideration, especially at points where rebar terminates, changes direction, or enters another structural element (like a beam entering a column). Development length calculations are complex and governed by specific building codes like ACI 318 (American Concrete Institute) and CSA A23.3 (Canadian Standards Association). Specialized engineering calculators can assist with these specific calculations. While a standard rebar length calculator for material takeoff might not directly calculate development length, it’s an underlying principle that informs the lap splice requirements you input.

Both lap splices and development length are fundamental to transferring stress within the reinforced concrete structure, ensuring it performs as designed. Miscalculating or improperly implementing these can lead to serious structural failures, which is why professional engineering consultation is paramount for all but the simplest projects.

From Calculation to Construction: Ordering and Best Practices

Once your rebar length calculator has provided you with precise quantities, the next phase involves ordering materials and implementing best practices on site. This is where efficient logistics and proper rebar support come into play.

Practical Considerations When Ordering Rebar

Ordering rebar isn’t just about quantity; it’s about making smart choices that streamline your project.

- Standard Stock Lengths: Rebar is commonly available in standard lengths such as 20 ft, 40 ft, and 60 ft. When generating your cut list from the calculator’s output, try to optimize your order to minimize waste from these stock lengths. This can significantly reduce costs.

- Total Weight for Delivery: Rebar is heavy. The total weight calculated by your rebar length calculator is crucial for logistics. It informs the type of transportation needed, whether a crane is required for offloading, and how the rebar will be moved around the job site. Planning for this in advance prevents delays.

- Staging Materials: Once delivered, rebar should be staged efficiently. Organize bundles by size and the section of the project they are intended for. Labeling bundles clearly to match your rebar plan grids will save significant time during placement.

- Cut Lists: Use the detailed output from your rebar length calculator to create precise cut lists for your rebar fabricator or for on-site cutting.

- Rebar Supports: Don’t forget the unsung heroes of rebar placement: rebar chairs and supports. These ensure the rebar is held at the correct height and spacing within the concrete pour, maintaining the crucial edge clearance (cover). We are proud to be America’s #1 in rebar chairs, having sold over 14 million units. Our red Hercules Rebar Chairs save time, money, and ensure code compliance. You can use our Hercules Rebar Chair Estimator to figure out exactly how many you’ll need for your project. Browse Our Products to see our full range of concrete supports.

Limitations of a Rebar Length Calculator and When to Seek Advice

While incredibly useful, it’s important to understand that a rebar length calculator provides estimates and has certain limitations.

- Estimates vs. Exact Plans: The calculator provides a highly accurate estimate, but it’s not a substitute for detailed structural engineering drawings or a comprehensive rebar bending schedule. Always compare the calculator’s output with your project’s official plans.

- Excludes Hooks and Bends: Most basic rebar length calculators primarily focus on straight lengths for slabs and linear elements. They typically do not account for complex bends, hooks (e.g., at the ends of beams or columns), or intricate shapes that require specialized fabrication.

- Complex Geometry: While you can break down irregular shapes into simpler ones, highly complex or curved concrete elements will require more advanced software or professional engineering input.

- Seismic Zones and Special Detailing: Projects in seismic zones or those requiring specific structural detailing (e.g., shear reinforcement, confinement ties) often have unique rebar requirements that go beyond simple linear length calculations. These necessitate an engineer’s expertise.

- Verifying with Structural Engineer: For any significant structural element—foundations, load-bearing walls, beams, or columns—always have your rebar plan and quantities verified by a licensed structural engineer. Their expertise ensures that the design meets all applicable building codes and can safely carry the intended loads. The calculator is a tool to assist, not replace, professional judgment.

Frequently Asked Questions about Rebar Estimation

How much extra rebar should I order for waste?

A common waste factor to add to your calculated rebar length is between 5% and 10%. For simple grids and straightforward projects, 5-8% might suffice. However, for projects with complex geometry, extensive splicing, or if you’re working with short stock lengths that lead to more off-cuts, it’s safer to budget for 10% or even slightly more. The goal is always to have slightly more material than you strictly need to avoid costly delays from running short.

What is edge clearance and why is it important?

Edge clearance, also known as concrete cover, is the distance from the surface of the rebar to the nearest exterior surface of the concrete. It’s incredibly important for several reasons:

- Corrosion Protection: The concrete cover protects the steel rebar from moisture, oxygen, and corrosive agents (like chlorides from de-icing salts), which can cause rust. Rusting rebar expands, leading to cracking and spalling of the concrete.

- Fire Resistance: Adequate concrete cover provides a thermal barrier, protecting the rebar from high temperatures during a fire, which could otherwise weaken the steel and compromise structural integrity.

- Bonding and Structural Performance: Proper cover ensures sufficient concrete surrounds the rebar for optimal bond development, allowing the rebar to effectively transfer tensile forces within the concrete.

- Code Compliance: Building codes specify minimum concrete cover requirements based on the type of concrete element (e.g., slab, beam, column), exposure conditions, and fire rating. Meeting these requirements is mandatory for safety and structural longevity.

How are different rebar sizes determined for a project?

Rebar size is primarily determined by the structural load requirements of the concrete element, as specified by a licensed structural engineer. It’s a critical design decision based on calculations of anticipated forces, concrete strength, and building codes.

- Light Residential Work: For projects like small patios, sidewalks, or thin slabs with minimal load, #3 rebar (3/8 inch diameter) is often sufficient.

- General Residential/Commercial: For more substantial elements like driveways, standard garage slabs, and non-load-bearing walls, #4 rebar (1/2 inch diameter) is a common choice.

- Foundations and Load-Bearing Structures: For foundations, footings, load-bearing walls, and beams that support significant weight, #5 rebar (5/8 inch diameter) or larger will typically be specified.

An engineer will consider the concrete’s compressive strength, the rebar’s yield strength, the element’s dimensions, and environmental factors to select the appropriate rebar size and spacing to ensure the structure can safely handle its intended loads. Never guess on rebar size for structural applications; always follow the engineer’s specifications.

Conclusion: Build with Confidence and Precision

In concrete construction, precision is paramount. A reliable rebar length calculator is an indispensable tool that empowers you to approach your projects with confidence and accuracy. By automating complex material takeoffs, it provides a clear roadmap for your rebar needs, translating directly into tangible benefits for your bottom line and project schedule.

Embracing the use of a rebar length calculator means:

- Accurate Budgeting: No more guesswork, leading to tighter financial control and fewer unexpected costs.

- Reduced Waste: Optimizing your rebar orders minimizes material waste, saving money and benefiting the environment.

- Time Savings: Quickly generate precise quantities, freeing up valuable time for other critical project tasks.

- Improved Structural Integrity: By ensuring you have the right amount of rebar, you contribute directly to the strength and longevity of your concrete structures.

And when it comes to proper rebar placement and maintaining that critical concrete cover, remember our red Hercules Rebar Chairs. As America’s #1 choice, with over 14 million units sold, our chairs save time, money, and ensure your rebar is perfectly positioned for code compliance and maximum structural performance.

For your next project, build with the confidence that comes from precise planning. Use our estimator for your next project and experience the Hercules difference!